44

6 Commissioning

6.6 O

2

Trim

6.6.1 Automatic Function Monitoring During Operation

6.6.1.1 Adjusted The Integrated O2 Controller (Optional)

This section explains only the operating steps needed to input the O

2

curve. Further informa-

tion on O

2

controller is contained in the publication DLT 5002 Commissioning Supplement for

the Optional ’Integrated O

2

Controller’.

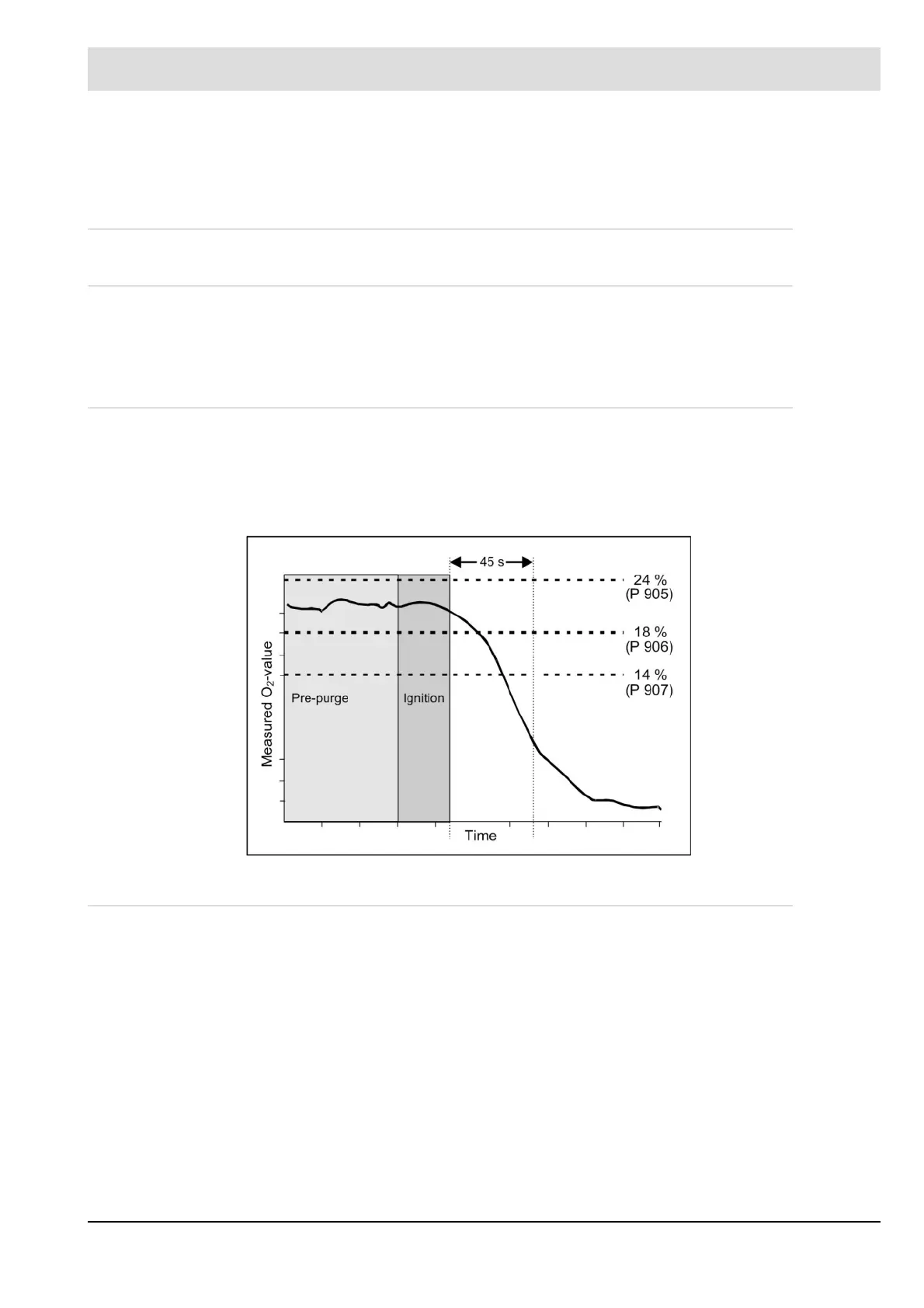

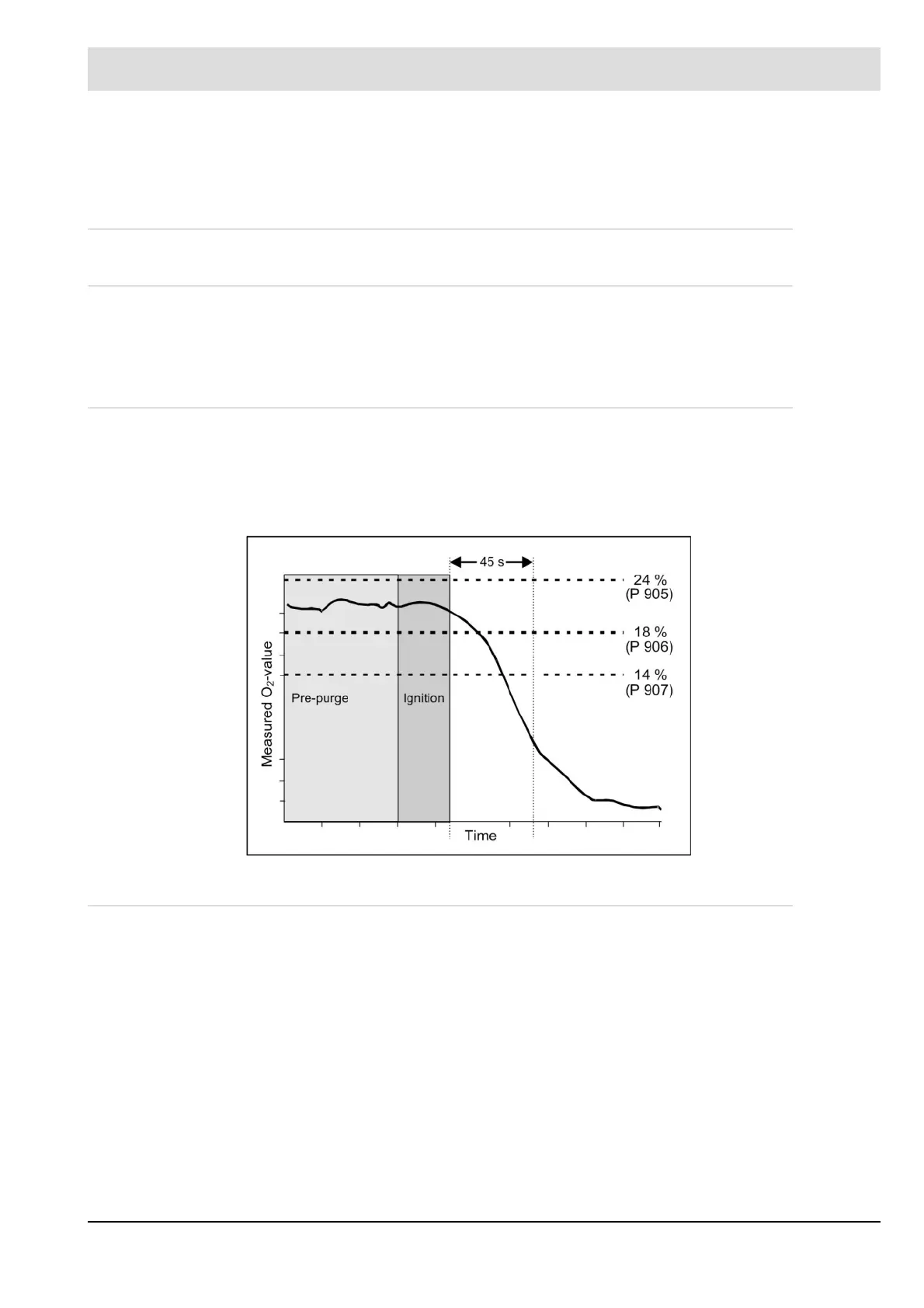

6.6.1.2 Test During Burner Start

The actual O

2

value is checked to ensure that during pre-purge it corresponds to the air value

(equal to or greater than 18 vol.% O

2

and less than 24 vol.% O

2

).

After ignition, the actual O

2

value must reach a value equal to or below 14% within 45 seconds.

Reaching the threshold value is monitored. If one of the two parameters is not met, O

2

trim is

deactivated. The control unit outputs the value “Base value without control”.

6.6.1.3 O

2

Monitoring Band

During burner operation, the actual O

2

value is continuously monitored for one maximum and

two minimum permissible values. These ranges are located around the O

2

setpoint as a func-

tion of firing rate. If the actual values stay outside these bands for a defined period, the control

system is deactivated and a “Fault” warning is output.

Thereafter, the control unit’s output (correction input) corresponds to “Base value without con-

trol” or “Base value with air deficiency”.

Loading...

Loading...