19

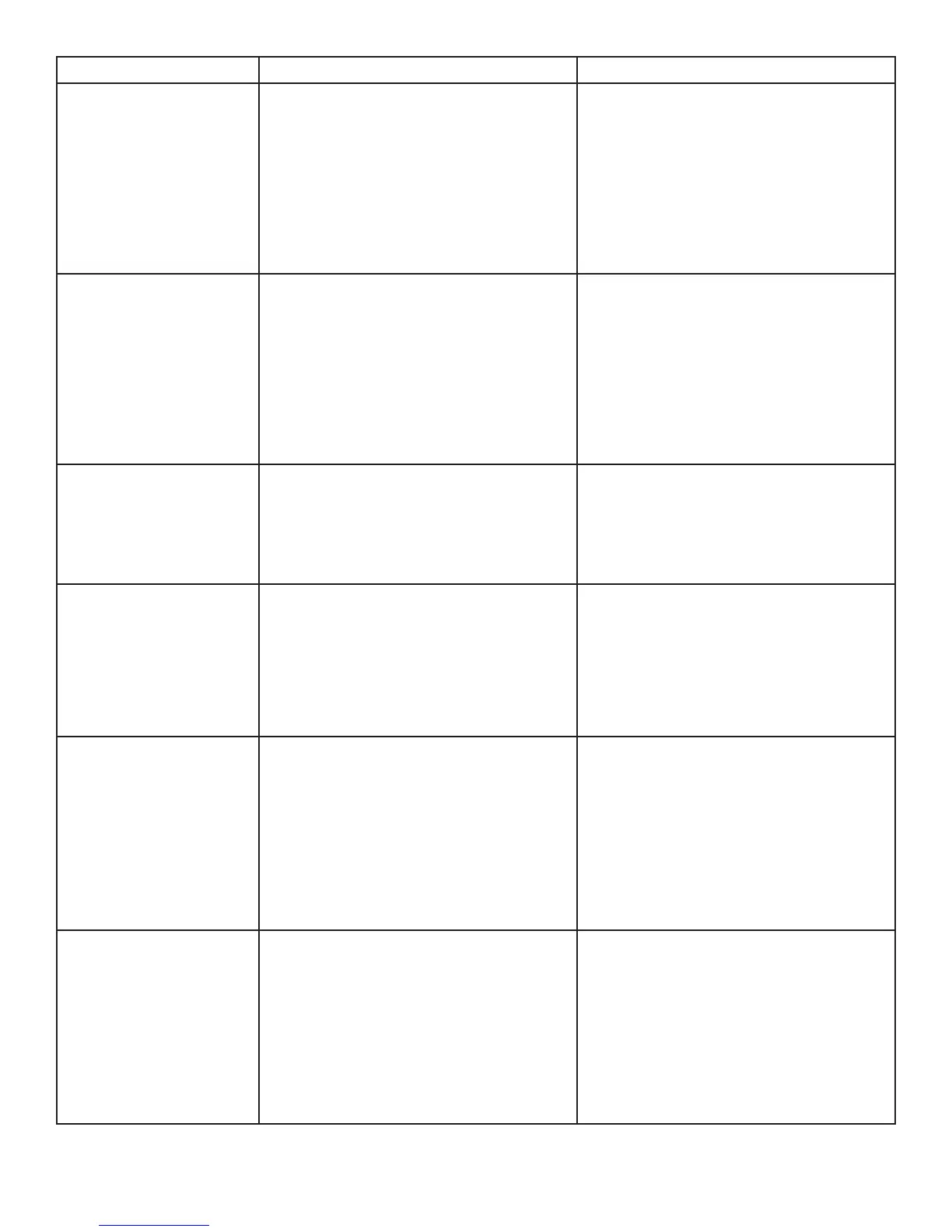

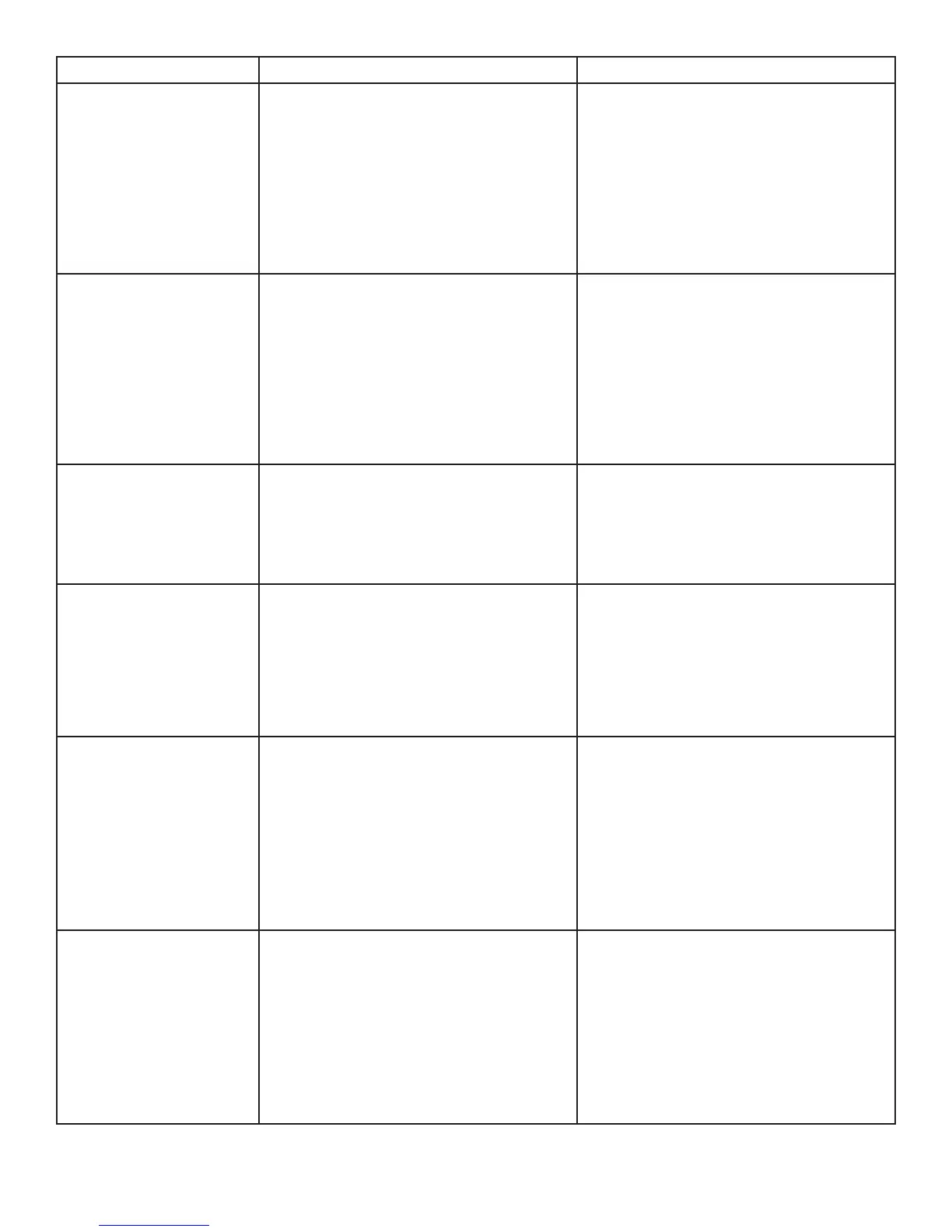

TROUBLE CAUSE REMEDY

Excessive foaming. 1. No ice in bin.

2. Incoming water or syrup temperature too

high.

3. CO

2

pressure too high.

4. Water ow rate too high.

5. Nozzle and diuser not clean.

6. Air in BIB lines.

1. Fill bin with ice and allow coldplate to

re-stabilize.

2. Correct prior to dispenser.

3. Adjust CO

2

pressure downward, but not less

than 70 PSI (0.483 MPA).

4. Re-adjust and reset ratio.

5. Remove and clean.

6. Bleed air from BIB lines.

Low or no carbonation. 1. Low or no CO

2

.

2. Low water pressure.

3. Worn or defective carbonator pump.

4. Backow preventer not allowing water to

ow.

5. Probe malfunctioning.

6. PCB malfunctioning.

1. Check CO

2

supply. Adjust CO

2

pressure to

70 PSI (0.483 MPA).

2. Need water booster kit.

3. Replace carbonator pump.

4. Replace backow preventer, noting the ow

direction arrow from pump to coldplate.

5. Replace probe.

6. Replace PCB.

Erratic ratio. 1. Incoming water and/or syrup supply not at

minimum owing pressure.

2. Foreign debris in water and/or syrup ow

control.

3. CO

2

regulator malfunction.

1. Check pressure and adjust.

2. Remove ow control from suspected valve

and clean out any foreign material to ensure

smooth spool movement.

3. Repair or replace CO

2

regulator.

Insucient soda ow

(carbonated drinks).

1. Insucient CO

2

supply pressure.

2. Shuto on mounting block is not fully open.

3. Foreign debris in soda ow control.

1. Verify incoming CO

2

pressure is between

70 PSIG (0.483 MPA) and 80 PSIG (0.552

MPA)

2. Open shuto fully.

3. Remove soda ow control from valve and

clean out any foreign material to ensure

smooth spool movement.

Insucient water ow (plain

water drinks).

1. Insucient incoming supply pressure.

2. Shuto on mounting block not fully open.

3. Foreign debris in water ow control.

4. Water ltration problem.

1. Verify incoming supply water pressure to

plain water inlet is a minimum of 50 PSI

(0.345 MPA) and a maximum of 100 PSI

(0.689 MPA).

2. Open shuto fully.

3. Remove water ow control from valve and

clean out any foreign material to ensure

smooth spool movement.

4. Service water system as required.

Insucient syrup ow. 1. Insucient CO

2

pressure to BIB pumps.

2. Shuto on mounting block not fully open.

3. Foreign debris in syrup ow control.

4. Defective BIB pump.

1. Adjust CO

2

pressure to BIB pumps to 80 PSI

(0.552 MPA) (min. 70 PSI (0.483 MPA). Do

not exceed manufacturer’s recommenda-

tions.

2. Open shuto fully.

3. Remove syrup ow control from valve and

clean out any foreign material to ensure

smooth spool movement.

4. Replace pump.

Loading...

Loading...