6300 Rev H User’s Manual

125-9106A Page 68

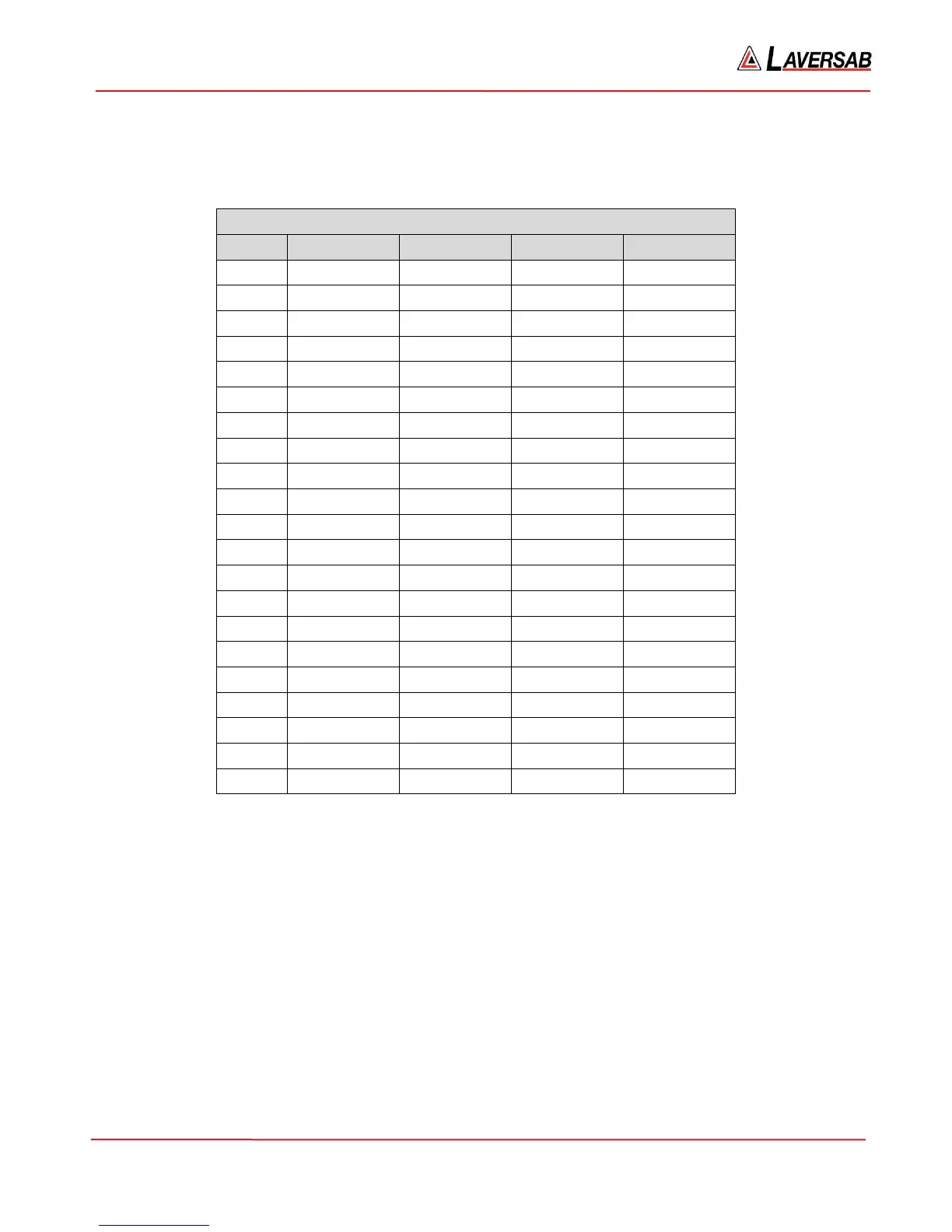

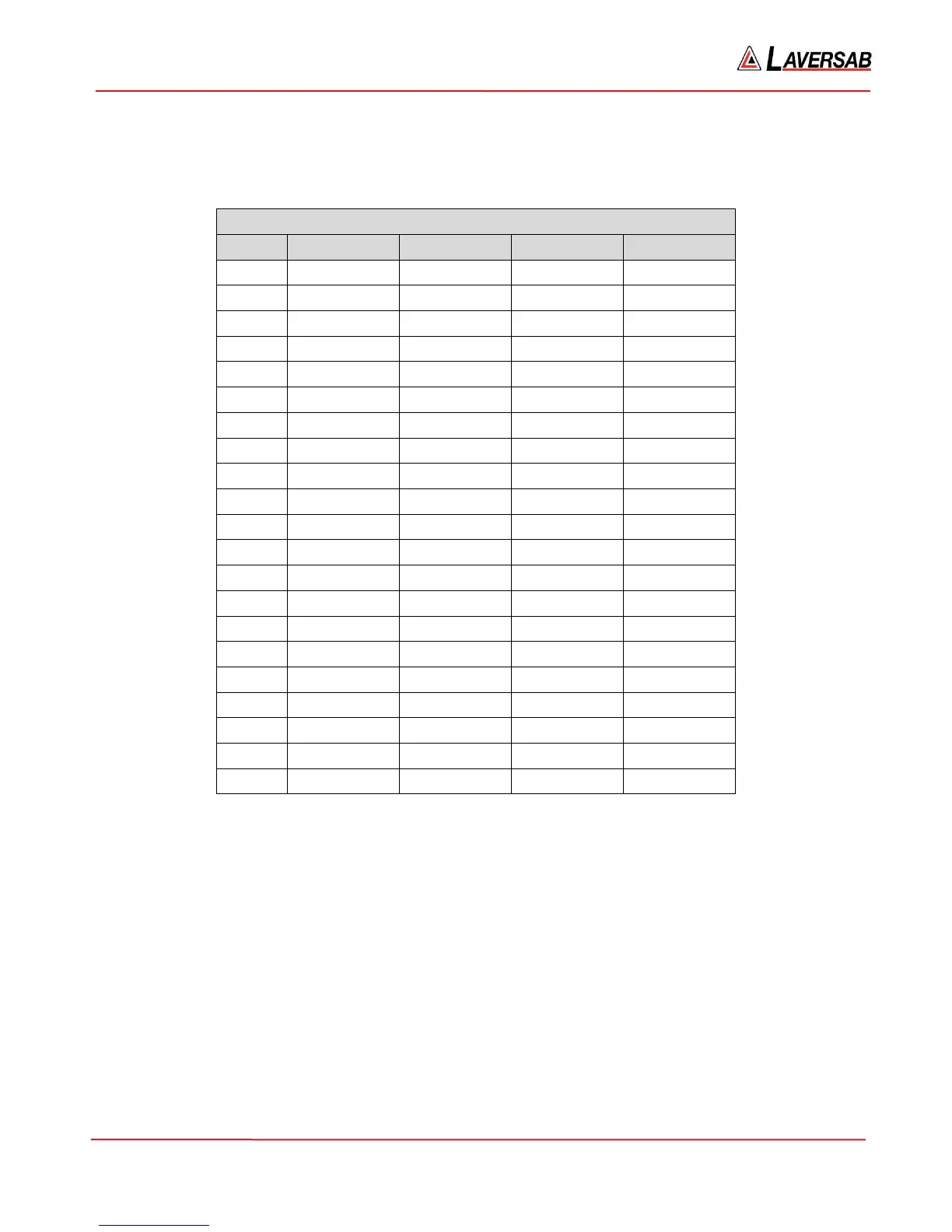

The table shown below provides the pressure values for QcinHg and PsinHg that need to be generated

for each point of the verification process. It also includes, for each point, the offset commands (followed

by specific values) that may be entered through the RS232 port. This table is referenced in the procedure

that follows.

Verification points

Point QcinHg Pitot offset PsinHg Static offset

1 0.000

1.600 No offset

2 0.000

3.200 S1 (10%)

3 0.000

6.400 S2 (20%)

4 0.000

9.600 S3 (30%)

5 0.000

12.800 S4 (40%)

6 0.000 No offset 16.000 S5 (50%)

7 3.000 P1 (10%) 16.000

8 6.000 P2 (20%) 16.000

9 9.000 P3 (30%) 16.000

10 12.000 P4 (40%) 16.000

11 15.000 P5 (50%) 16.000

12 18.000 P6 (60%) 16.000

13 21.000 P7 (70%) 16.000

14 24.000 P8 (80%) 16.000

15 27.000 P9 (90%) 16.000

16 30.000 No offset 16.000

17 0.000

19.200 S6 (60%)

18 0.000

22.400 S7 (70%)

19 0.000

25.600 S8 (80%)

20 0.000

28.800 S9 (90%)

21 0.000

32.000 No offset

Offsets are entered through Hyperterminal as follows:

For Static offsets: Sn=xxxx followed by ENTER

For Pitot offsets: Pn=xxxx followed by ENTER

where n is the offset number between 1 and 9, and ‘xxxx’ is the positive or negative offset value equal to

(Actual value – Pressure Standard value).

For example, at point 2 (Pressure Standard = 3.200 PsinHg), if the 6300 Static Actual value is 3.198, the

offset value will be (3.198 – 3.200 = -0.002), and the command sent to the 6300 would be:

S1=-0.002 followed by ENTER

At point 2, if the 6300 Static Actual value is 3.201, the offset value will be (3.201 – 3.200 = 0.001), and the

command sent to the 6300 would be:

S1=0.001 followed by ENTER

Loading...

Loading...