6300 Rev H User’s Manual

125-9106A Page 67

16. The calibration points have now been entered. Press GO to save the points and exit this screen.

If you press CANC, the calibration will be void. When GO is pressed, the screen will appear

similar to the one shown below.

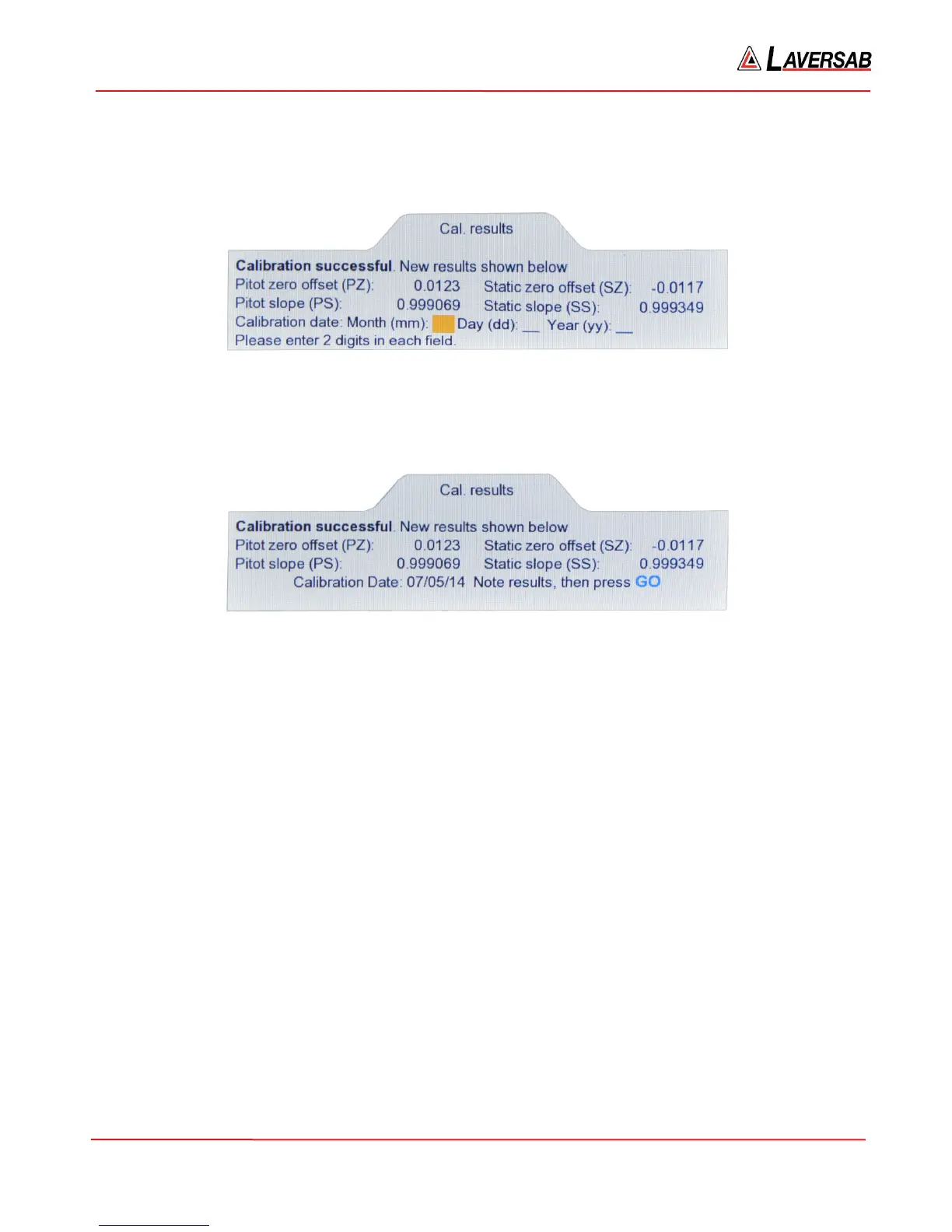

Figure 6.8

17. The calibration results showing the zero offset values and slope values are displayed in this

screen. Enter the current date as the ‘Calibration date’. After the Year has been entered, the

screen will appear similar to the one shown below.

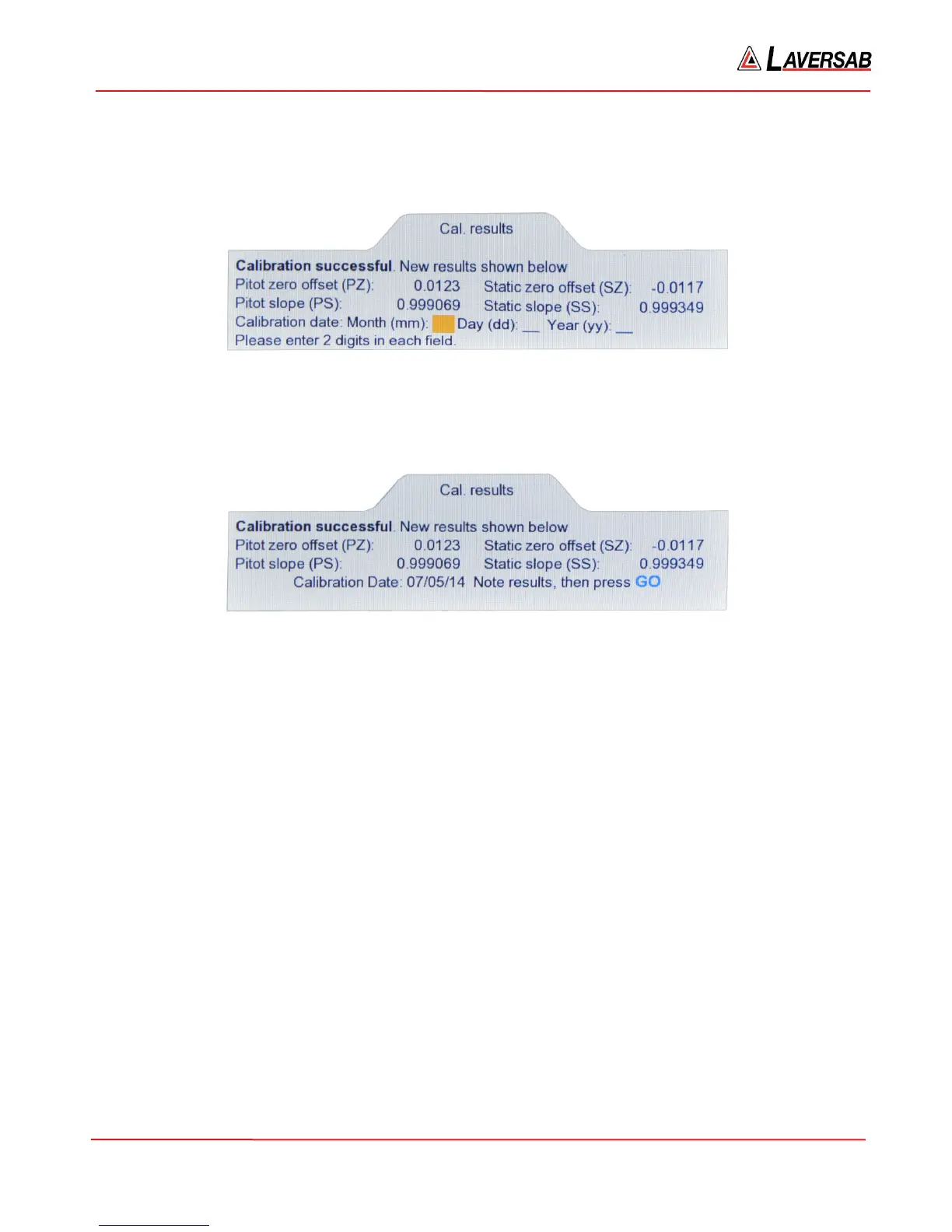

Figure 6.9

18. Note the calibration results, then press GO. Calibration is complete. The Lower section of the

screen will blank out. The Actual values displayed in the Upper section should typically be 0.000

QcinHg for Pitot and 32.000 inHg for Static.

19. Do not disconnect the Pressure Standard. It will be required for the verification process shown

below.

6.5 VERIFICATION PROCEDURE

During the verification process, it is possible to correct for the non-linearity of the transducers at each

verification point. To do this, it is necessary to send the non-linearity offsets from a PC to the RS232 serial

port on the 6300, using a program similar to Hyperterminal. Details of this setup are provided in Section

8.1.

Once communication between the 6300 and the PC has been setup and verified, in Hyperterminal, enter

the command:

CP=xxxxxx followed by ENTER, where ‘xxxxxx’ is the calibration password.

If the password is correct, the 6300 will echo back a ‘0’. This completes the setup required for entering the

non-linearity offsets, which will be entered at various points in the verification process detailed below.

Loading...

Loading...