A

A

C

C

S

S

6

6

0

0

6

6

D

D

i

i

g

g

i

i

t

t

a

a

l

l

A

A

C

C

S

S

e

e

r

r

v

v

o

o

d

d

r

r

i

i

v

v

e

e

M

M

a

a

n

n

u

u

a

a

l

l

R

R

e

e

v

v

1

1

.

.

0

0

Tel: (86)755-26434369 20 Website: www.leadshine.com

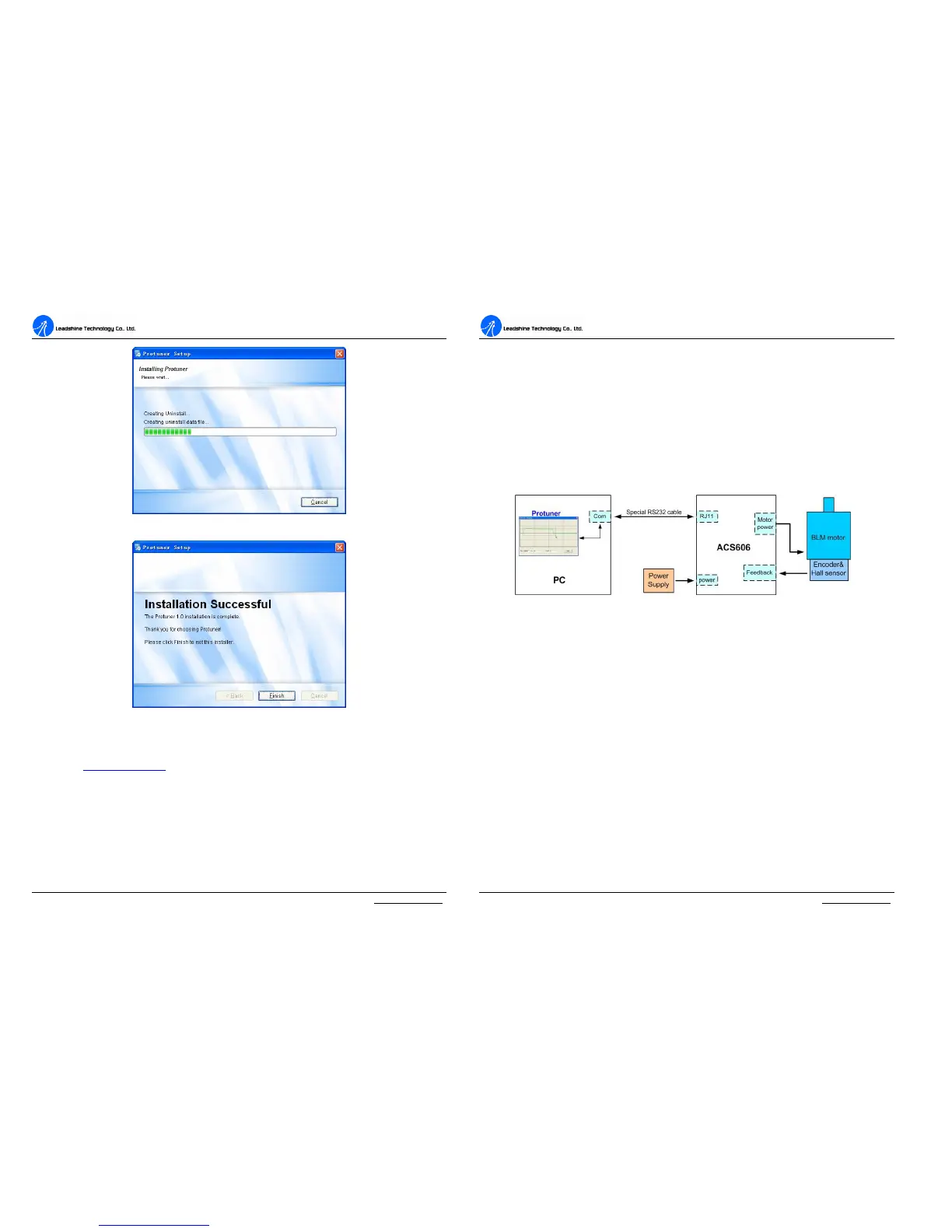

Figure 18: Installing the ProTuner

Figure 19: Finish installation

Note: Leadshine also offers special version ProTuner which does not need installation. Please visit

our website www.leadshine.com for latest ProTuner.

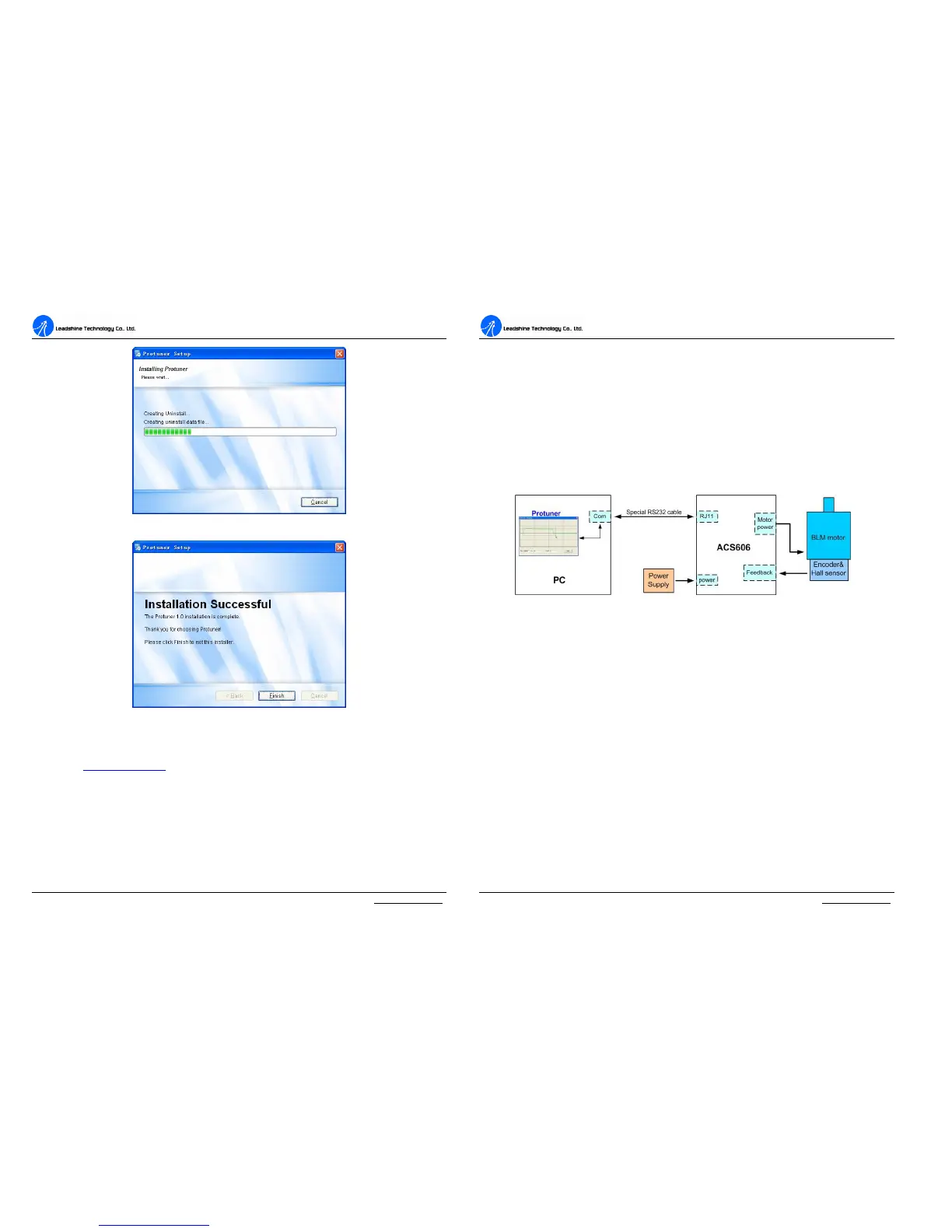

Hardware Configurations before Tuning

ProTuner uses PC RS232 port to communicate with the ACS606. The ACS606 has a

RJ-11 connector in which a special RS232 cable is connected to PC RS232 port.

Before opening ProTuner to tune the ACS606, the following configuration must be

A

A

C

C

S

S

6

6

0

0

6

6

D

D

i

i

g

g

i

i

t

t

a

a

l

l

A

A

C

C

S

S

e

e

r

r

v

v

o

o

d

d

r

r

i

i

v

v

e

e

M

M

a

a

n

n

u

u

a

a

l

l

R

R

e

e

v

v

1

1

.

.

0

0

Tel: (86)755-26434369 21 Website: www.leadshine.com

achieved as figure 20.

1. A power supply which has sufficient output current at related voltage;

2. DC brushless servo or AC servo motor(power range: 10 – 200W) with

encoder and hall sensor feedback.

3. Table PC/Notebook with one RS232 communication port at least or a USB

to RS232 adapter. Recommend using Table PC with RS232 port.

4. A special RS232 cable offered by Leadsine in which one end is a RJ-11

connector and the other end is a DB9 connector.

Figure 20: Configuration and connections before Tuning

Note:

1. If it is the first installation, strongly recommended that tuning the ACS606

and AC servo motor without motor shaft coupling to any load. After basic

values of the parameters are achieved, connect the motor to the load for

further tuning. These basic parameters can also be used for other drives

with the same servo motors.

2. Please double check the connections and make sure the motor would not

jump off before powering on the drive if start at a high acceleration.

3. In order to setup communication between the drive and ProTuner, the

ACS606 should be powered.

ProTuner for the ACS606 at Startup Window

Power on the ACS606. The green LED indicator should be on and the motor shaft

should be locked if the servo system is OK. Please refer to the protection functions

Loading...

Loading...