5.4303.8558.0 -

7-12 Maintenance

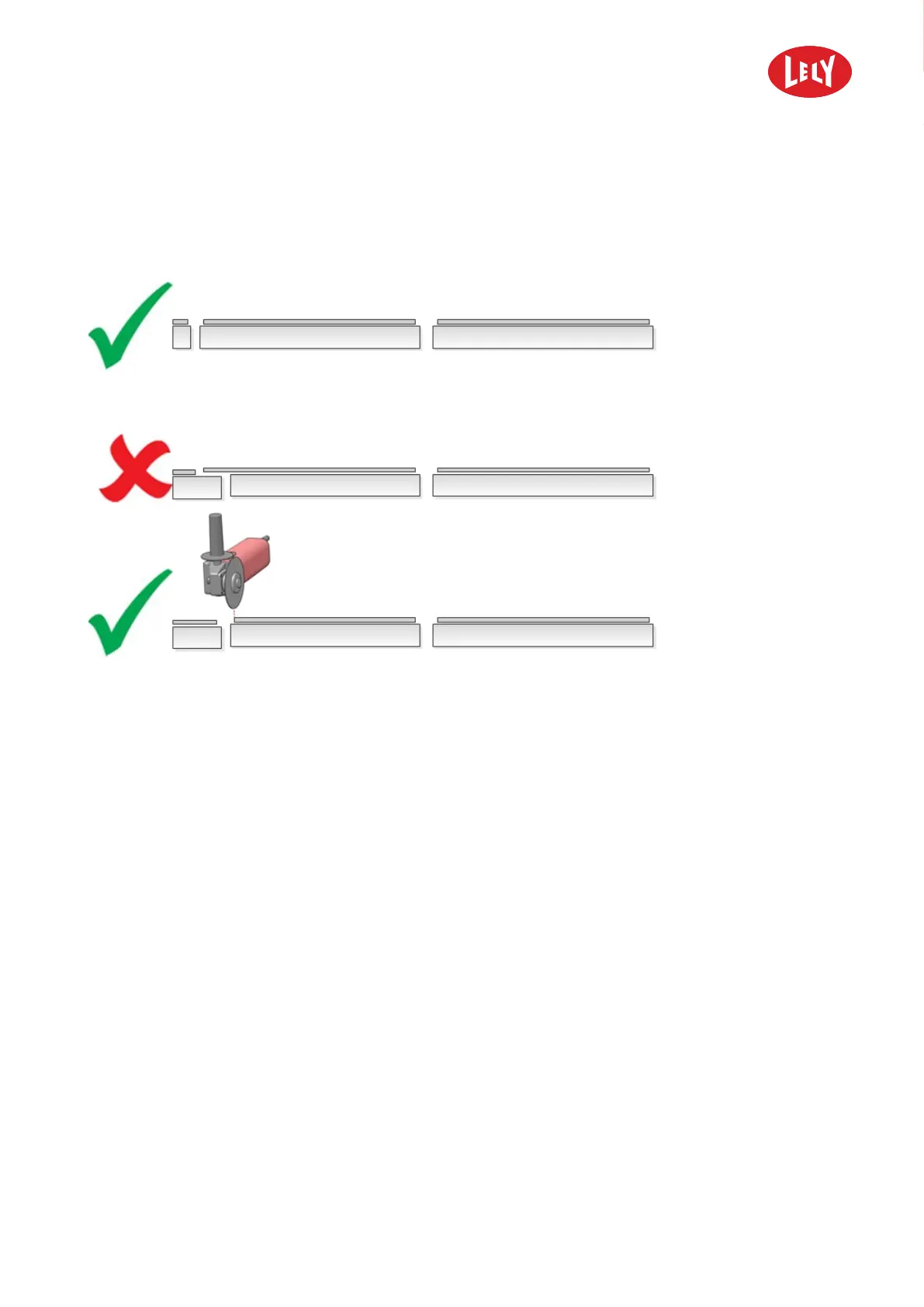

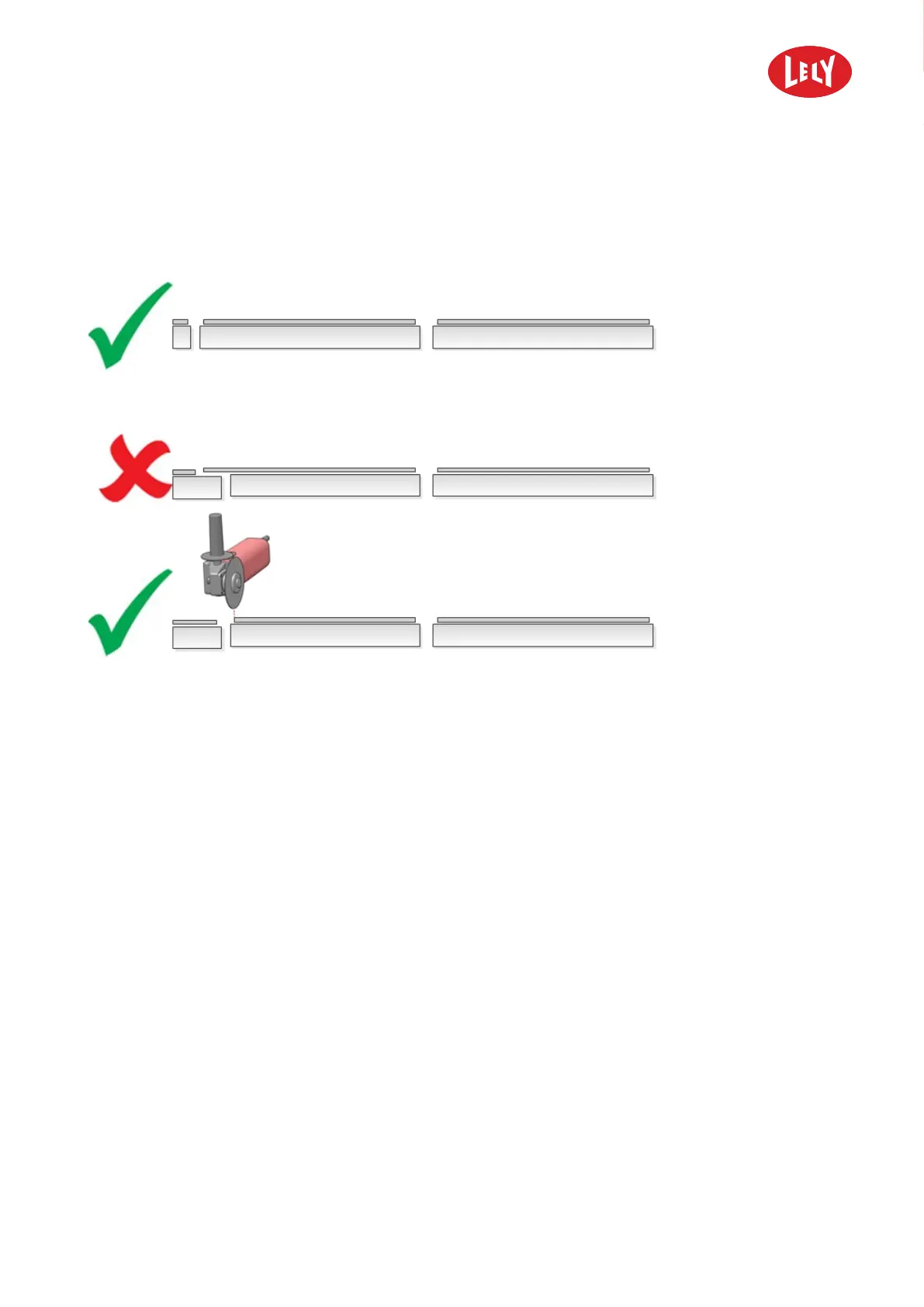

2. Put the new strip on the floor. If necessary cut the strip with a grinder. Make sure:

• The machine will find the metal strip on the exact same position as the old one.

• The strip does not stick out over the edge of the concrete plate or on other surfaces than concrete

plates: leave at least 10 mm of space between two metal strips.

Figure 31. Metal strip positioning (2)

3. Mark the position of the holes. Start to mark the hole in the center (A) of the strip. Mark the slotted

holes (B) and (C) in the center of the holes.

4. Drill new holes in the floor with a 10 mm drill and >65 mm deep.

5. Clean the holes.

6. Insert S10 plugs.

7. Use a bit T30 to tighten the metal strip with the screws (BT 6x65). Tighten only with a torque of 20 Nm.

It must still be possible that the metal strip can shrink and expand a bit when temperature changes

occur.

Close-up

1. Manually drive the machine to the charger.

2. Put the machine into operation.

7.3.11 Test the Inductive Sensors

Preparation

1. Take the machine out of operation.

2. Drive the machine to the charging station.

in n o vato rs in agriculture

Loading...

Loading...