Page 42

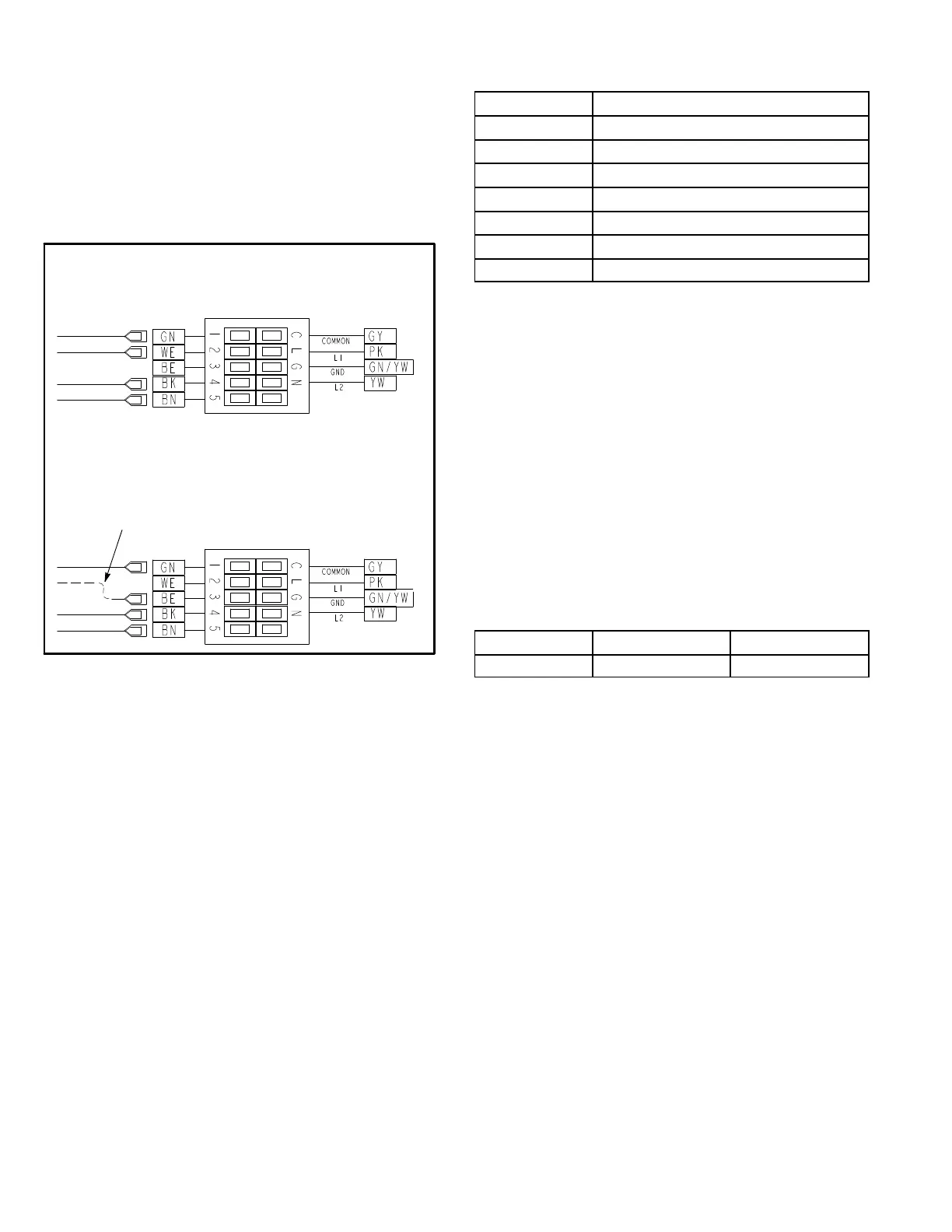

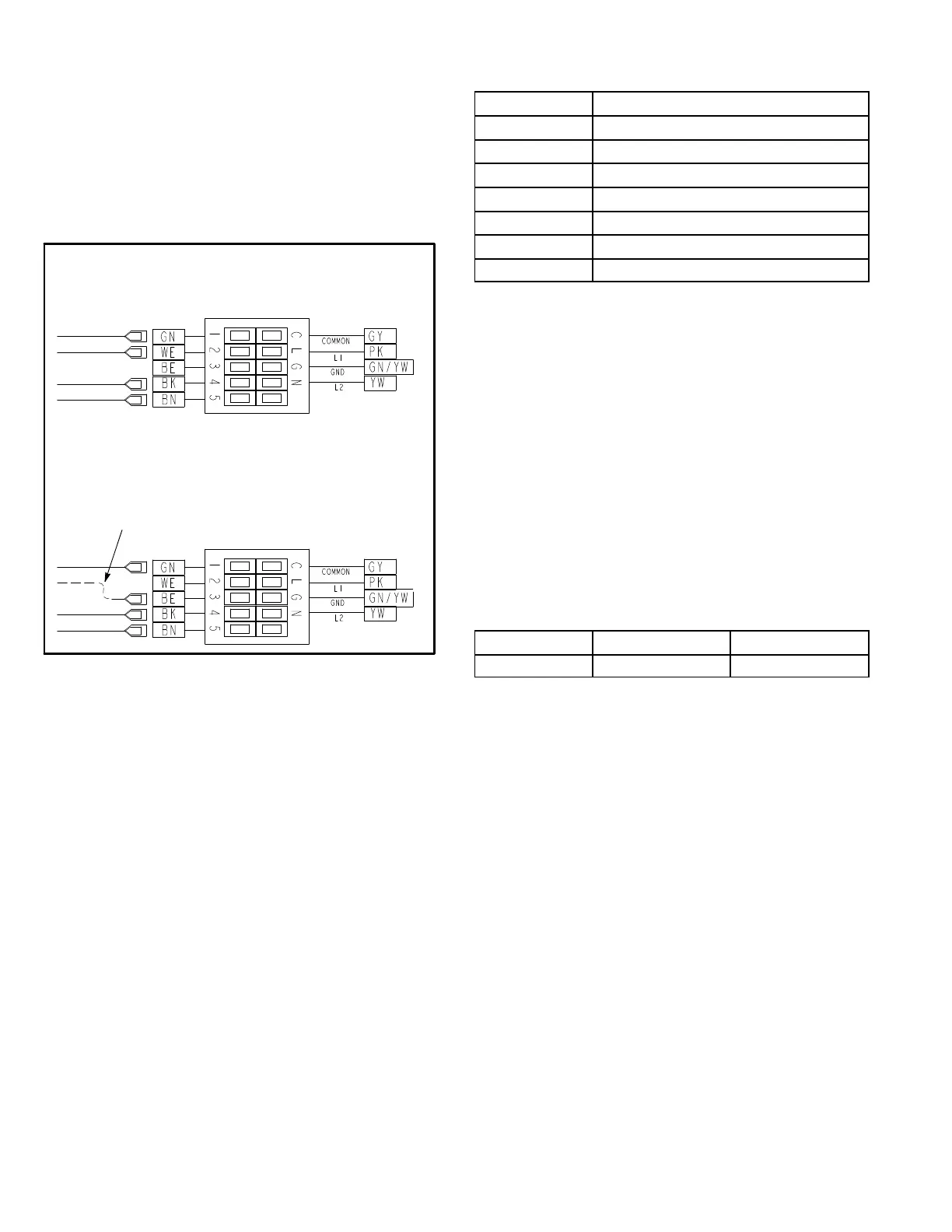

C-Determining Unit CFM - Multi-Stage, Direct Drive

Blowers

1- Refer to multi-stage direct drive blower tables, the

measured static pressure, and the factory-set blower

speed to determine CFM.

2- If CFM is lower than the design specified CFM, move

the leads as shown in figure 10 for 208/230 volt single

phase units.

DIRECT DRIVE BLOWER LEADS

1 PHASE

B3-W1

B3-G

B3-Y1

B3-W2

B3-W1

B3-G

B3-Y1

B3-W2

DEFAULT

Line Voltage24VAC

INCREASE SPEED

To increase the speed, move the

lead labeled B3-W1 from the white

(WE) wire to the blue (BE) wire.

Note - Operating units using other wire

connections in heating mode may result in

operation outside of this unit's FER rating.

FIGURE 10

D-Determining Unit CFM - Belt Drive Blowers

IMPORTANT - KGB074, 090S4T blower (G thermostat)

CFM MUST BE ADJUSTED IN HIGH SPEED. Discon

nect factory-installed J350 low speed connector from

P350. Connectors are located near the bottom of the

control box. Connect J351 high speed connector to

P350. Once blower CFM is set, J350 can be reconnect

ed to operate the blower on low during ventilation only

demands. See table 4.

1- The following measurements must be made with air fil

ters in place.

2- With all access panels in place, measure static pres

sure external to unit (from supply to return). Blower per

formance data is based on static pressure readings

taken in locations shown in figure 7.

Note - Static pressure readings can vary if not taken where

shown.

TABLE 4

TWO-SPEED BLOWER OPERATION

KGB074, 090S4T UNITS

Thermostat Blower Speed

G (P350/J350)* Low

G (P350/J351) High

W1 High

W2 High

Y1 Low

Y2 High

Dehum High

*Factory-installed jack/plug connection.

3- Measure the indoor blower wheel RPM.

4- Referring to belt drive blower tables, use static pres

sure and RPM readings to determine unit CFM. Use

the air resistance tables when installing units with any

of the options or accessories listed.

5- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clock

wise to increase CFM. Turn counterclockwise to de

crease CFM. See figure 11 Do not exceed minimum

and maximum number of pulley turns as shown in table

5.

6- KGB074S4T and 090S4T Unit Only -

If low speed during ventilation is desired, replace J351

connector with J350.

TABLE 5

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Min. Turns Open Maxi. Turns Open

A Section No minimum 5

E-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main

tained. Tension new belts after a 24-48 hour period of op

eration. This will allow belt to stretch and seat grooves.

Make sure blower and motor pulley are aligned as shown in

figure 12.

1- Loosen four bolts securing motor base to mounting

frame. See figure 11.

2- To increase belt tension -

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

3- To loosen belt tension -

Slide blower motor upward to loosen the belt. This de

creases the distance between the blower motor and

the blower housing.

4- Tighten four bolts securing motor base to the mounting

frame.

Loading...

Loading...