Page 61

3-Testing Gas Supply Pressure

When testing gas supply pressure, connect test gauge to the

inlet pressure tap located on unit gas valve GV1. Test sup

ply gas pressure with unit firing at maximum rate (both

stages energized). Make sure the reading falls within the

range of the following values. Low pressure may result in

erratic operation or “underfire.” High pressure can result in

permanent damage to the gas valve or “overfire.” For nat

ural gas units, operating pressure at the unit gas connec

tion must be between 4.5”W.C. and 10.5”W.C. For L.P.

gas units, operating pressure at the unit gas connection

must be between 10.5”W.C. and 13.0”W.C.

On multiple unit installations, each unit should be checked

separately while operating at maximum rate, beginning with

the one closest to the supply gas main and progressing to

the one furthest from the main. Multiple units should also

be tested with and without the other units operating.

Supply pressure must fall within the range listed in the

previous paragraph.

4-Check and Adjust Manifold Pressure

After line pressure has been checked and adjusted, check

manifold pressure. Move test gauge to the outlet pressure

tap located on unit gas valve GV1. See figures 20 and 21

for location of pressure tap on the gas valve.

The manifold pressure is factory set and should not re

quire adjustment. If manifold pressure is incorrect and no

other source of improper manifold pressure can be found,

the valve must be replaced. See figure 20 and 21 for loca

tion of gas valve (manifold pressure) adjustment screw.

All gas valves are factory regulated. The gas valve should

completely and immediately cycle off in the event of gas or

power failure. The manual shut‐off knob can be used to im

mediately shut off gas supply.

CAUTION

For safety, connect a shut‐off valve between the

manometer and the gas tap to permit shut off of

gas pressure to the manometer.

Manifold Adjustment Procedure

1- Connect test gauge to the outlet pressure tap on the

gas valve. Start the unit (call for second stage heat)

and allow five minutes for the unit to reach steady

state.

2- While waiting for the unit to stabilize, notice the

flame. The flame should be stable without flashback

and should not lift from the burner heads. Natural

gas should burn basically blue with some clear

streaks. L.P. gas should burn mostly blue with some

clear yellow streaks.

3- After allowing the unit to stabilize for five minutes,

record the manifold pressure and compare to the val

ues below.

Natural Gas Units - Low Fire - 2.0” w.c.

Natural Gas Units - High Fire - 3.5” w.c.

LP Gas Units - Low Fire - 5.9” w.c.

LP Gas Units - High Fire - 10.5” w.c.

5-Proper Gas Flow

Furnace should operate at least 5 minutes before checking

gas flow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more ac

curate time.) Divide by two and compare to time in table 24.

Seconds in table 24 are based on a 1 cu.ft. dial and gas val

ue of 1000 btu/ft

3

for natural and 2500 btu/ft

3

' for LP. Adjust

manifold pressure on gas valve to match time needed.

NOTE - To obtain accurate reading, shut off all other gas

appliances connected to meter.

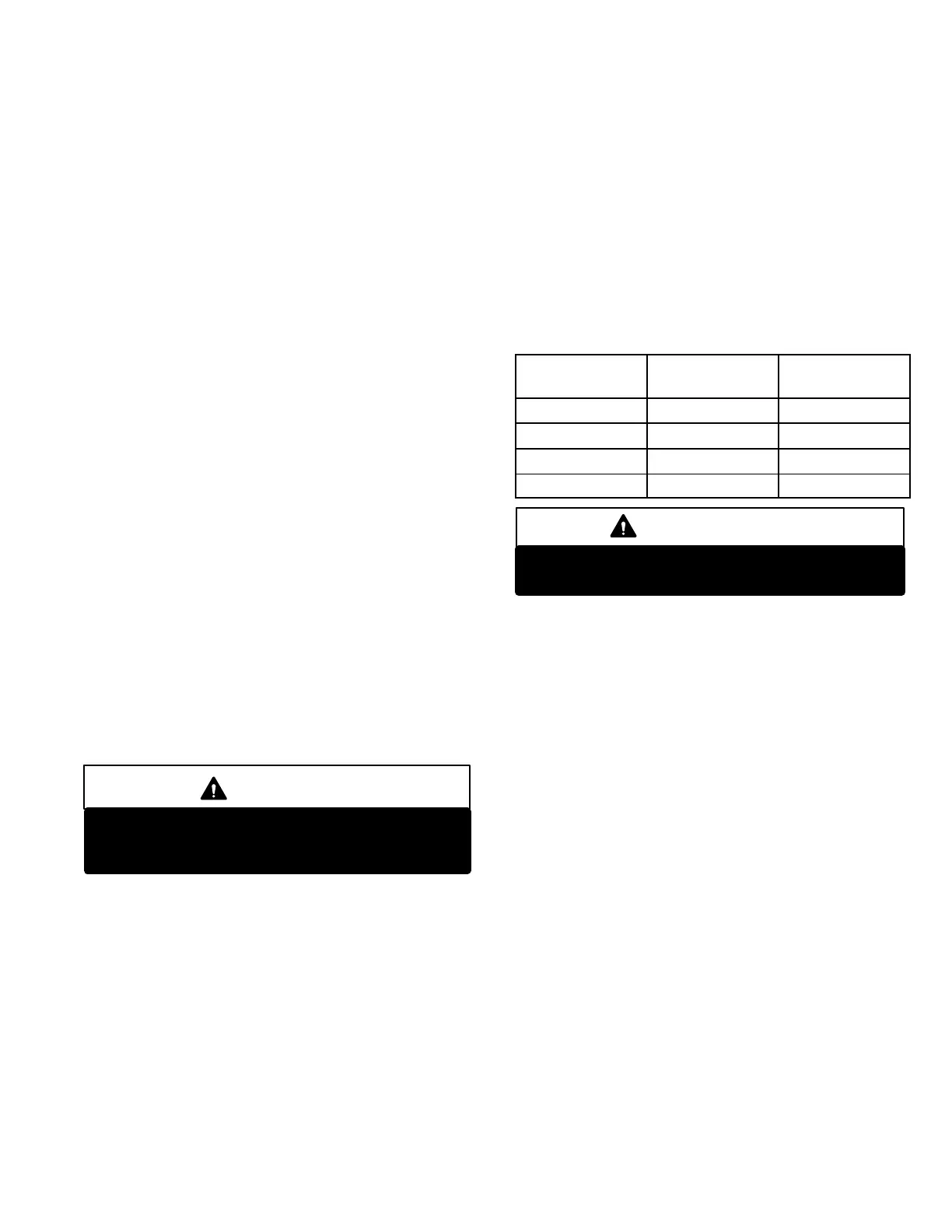

TABLE 24

Unit Input Rate

Seconds for

Natural

Seconds for

Propane

65,000 55 138

105,000 34 86

108,000 33 83

150,000 24 60

IMPORTANT

Disconnect heating demand as soon as an

accurate reading has been obtained.

6-Heat Exchanger

To Access or Remove Heat Exchanger From Unit:

1- Turn off gas and electric power.

2- Remove access panel(s) and unit center mullion.

3- Remove gas valve, manifold assembly and burn

ers.

4- Remove combustion air inducer. Pay careful attention

to the order in which gaskets and orifice are removed.

5- Support heat exchanger (to prevent it from falling

when final screws are removed.)

6- Remove screws supporting heat exchanger.

7- To install heat exchanger, reverse procedure. Be sure

to secure all wires and check plumbing and burner

plate for airtight seal. Screws must be torqued to 35

in.‐lbs. to ensure proper operation.

7-Flame Sensing

Flame current is an electrical current which passes from the

ignition control through the sensor electrode during unit op

eration. The current passes from the sensor through the

flame to the ground electrode (located on the flame elec

trode) to complete a safety circuit. The electrodes should be

located so the tips are at least 1/2” (12.7 mm) inside the

flame envelope. Do not bend electrodes. To measure flame

current, follow the procedure on the following page:

NOTE-Electrodes are not field adjustable. Any alter

ations to the electrode may create a hazardous con

dition that can cause property or personal injury.

1- Disconnect power to unit.

Loading...

Loading...