Page 68

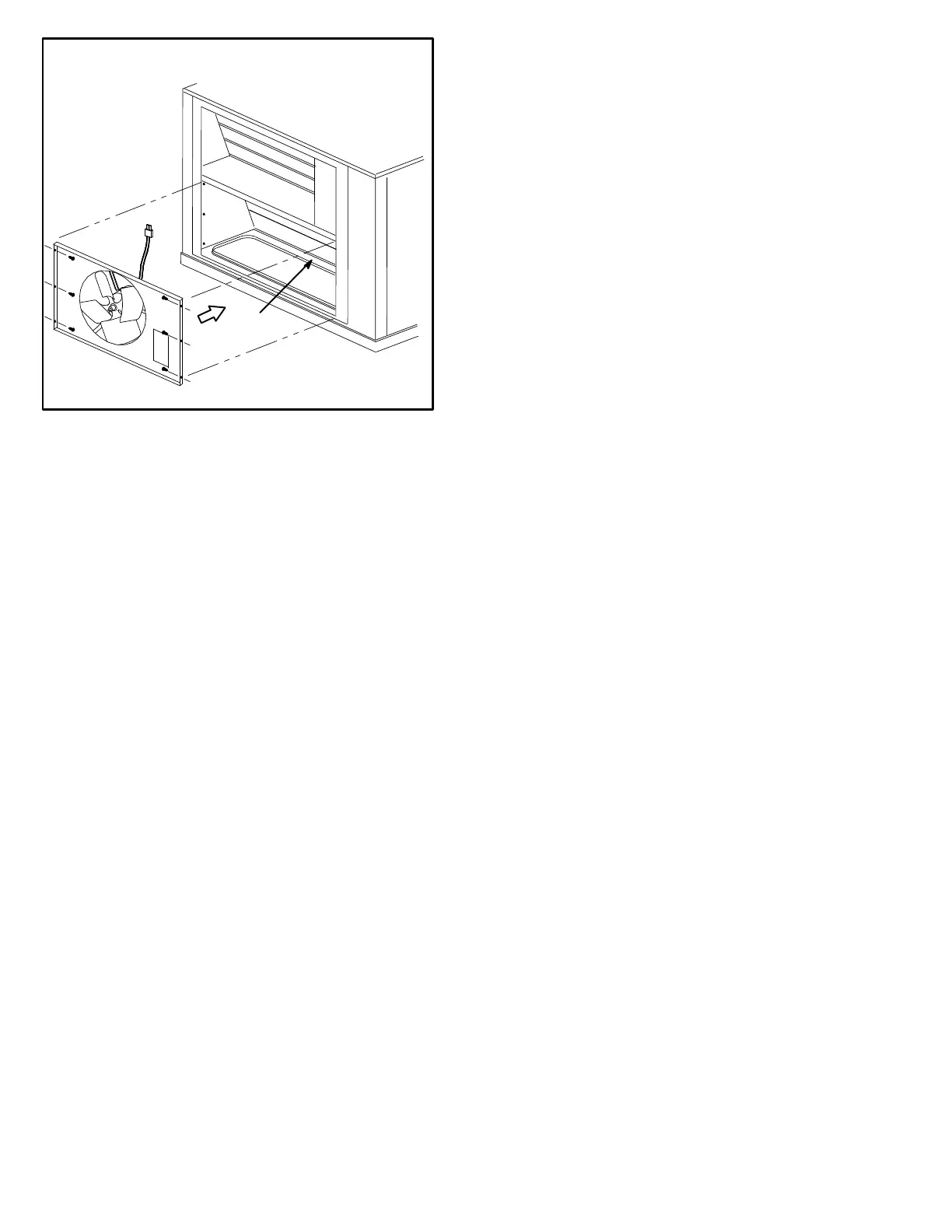

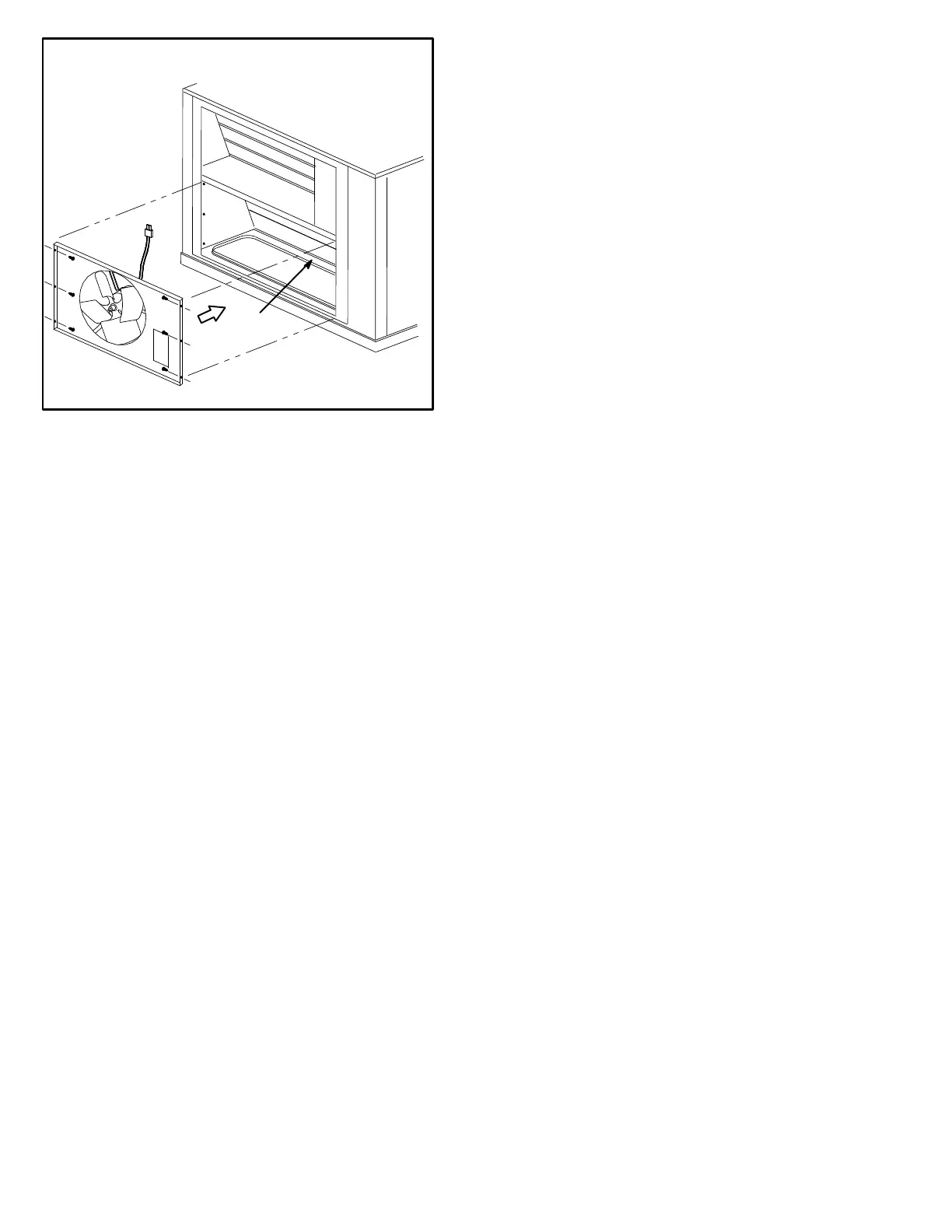

FIGURE 30

P18

POWER EXHAUST FAN

J18 JACK ON

UNDERSIDE OF

DIVISION PANEL

CONNECT P18 TO J18

BEFORE SECURING

EXHAUST FAN IN

PLACE

H-Optional Cold Weather Kit

Electric heater is available to automatically control the

minimum temperature in the gas burner compartment.

Heater is C.S.A. certified to allow cold weather opera

tion of unit down to ‐60° F (‐50° C ).

The kit includes the following parts:

1- The strip heater (HR6) is located as close as possible to the

gas valve. The strip heater is rated at 500 Watts

2- A thermostat mounting box is installed on the wall of

the compressor compartment. Included in the box

are the following thermostat switches:

a - Thermostat switch (S59) is an auto‐reset SPST N.C.

switch which opens on a temperature drop. The

switch is wired in series with 24v power and the com

bustion air blower switch. When the temperature

drops below ‐30° F (-35° C) the switch opens and the

gas heat section is de‐energized. The switch automati

cally resets when the heating compartment tempera

ture reaches -10° F (-12° C).

b - Thermostat switch (S60) is an auto‐reset SPST

N.C. switch which opens on a temperature rise.

The switch is wired in series with HR6. When the

temperature rises above 20° F (‐7° C) the switch

opens and the electric heater is de‐energized. The

switch automatically resets when the heating com

partment temperature reaches ‐10° F (23.3° C).

c -Thermostat switch (S61) is an auto‐reset SPST

N.O. switch which closes on a temperature drop.

The switch is wired in series with HR6. When tem

perature drops below 20° F (‐7° C) the switch clos

es and electric heater is energized. The switch au

tomatically opens when heating compartment

temperature reaches 70° F (21° C).

I-Control Systems

Three different types of control systems may be used with

the KGB series units. All thermostat wiring is connected to

TB1 located in the control box. Each thermostat has addi

tional control options available. See thermostat installation

instructions for more detail.

1- Electro‐mechanical thermostat (13F06)

The electro‐mechanical thermostat is a two stage heat /

two stage cool thermostat with dual temperature levers.

A non‐switching or manual system switch subbase

may be used.

2- Electronic thermostat (see price book)

Any two stage heat / two stage cool electronic ther

mostat may be used.

3- Honeywell T7300 thermostat (60L59)

The Honeywell T7300 thermostat is a programmable, in

ternal or optional remote temperature sensing thermo

stat. The T7300 provides occupied and unoccupied

changeover control.

J-Smoke Detectors A17 and A64

Photoelectric smoke detectors are a field installed option.

The smoke detectors can be installed in the supply air duct

(A64), return air section (A17), or in both the supply duct

and return air section.

K-Dirty Filter Switch S27

The dirty filter switch senses static pressure increase indi

cating a dirty filter condition. The switch is N.O. and closes

at 1” W.C. (248.6 Pa) The switch is mounted in the filter sec

tion on the left unit mullion.

L-Indoor Air Quality (CO

2

) Sensor A63

The indoor air quality sensor monitors CO

2

levels and re

ports the levels to the economizer enthalpy control A6. Con

troller A6 adjusts the economizer dampers according to the

CO

2

levels. The sensor is mounted next to the indoor ther

mostat or in the return air duct. Refer to the indoor air quality

sensor installation instructions for proper adjustment.

M-LP / Propane Kit

All units require a natural to LP /propane kit. The kit for sin

gle stage units include one LP spring , seven burner orifices,

and three stickers. Two stage kits include the same but has a

prove switch used to lock out first stage on the combustion air

inducer. For more detail refer to the natural to LP gas

changeover kit installation instructions.

N-Drain Pan Overflow Switch S149

(optional)

The overflow switch is used to interrupt cooling operation

when excessive condensate collects in the drain pan. The

N.O. overflow switch is controlled by K220 and DL46 relays,

located in the unit control panel. When the overflow switch

closes, 24VAC power is interrupted and after a five-second

delay unit compressors are de-energized. Once the conden

sate level drops below the set level, the switch will open. Af

ter a five-minute delay the compressor will be energized.

Loading...

Loading...