LGMG North America Inc.

Operation and Safety Manual

96

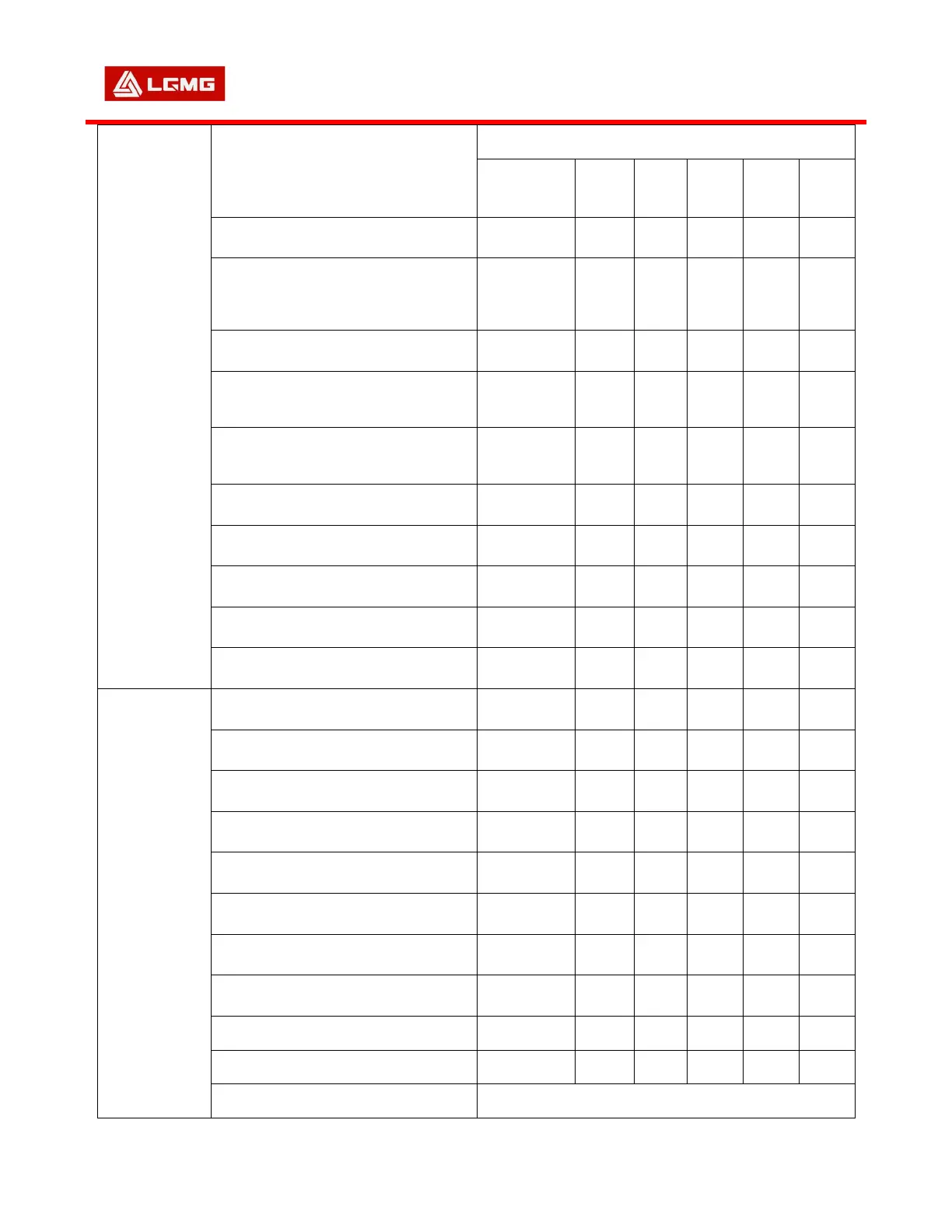

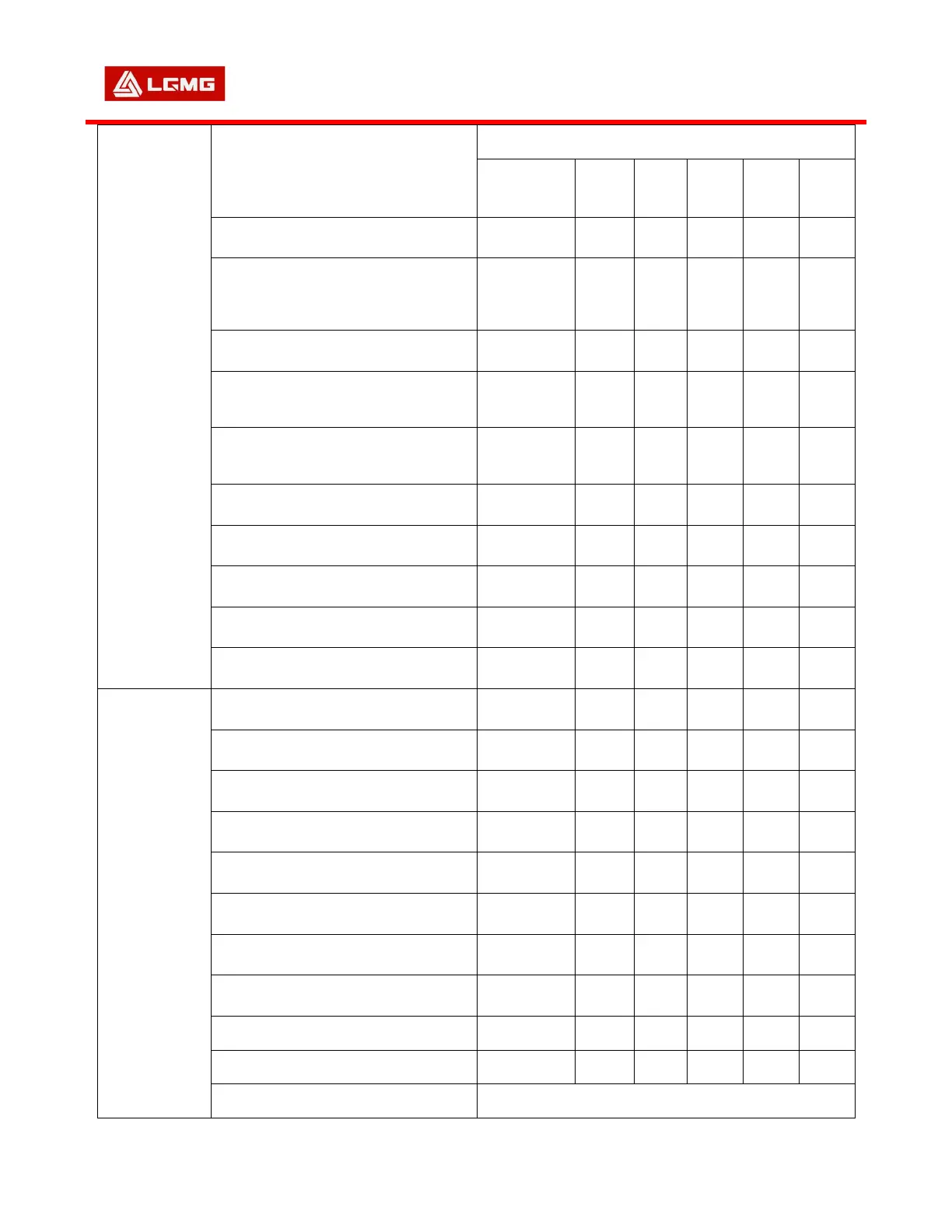

and connector are secure and not

damaged

Ensure the emergency stop switch, key

switch and plug switch on the lowering

control panel and their wiring are

secure and not damaged

Ensure the warning lamp and horn

function normally

Ensure the motor, motor controller,

relay and ECU wirings are secure and

not damaged

Ensure the wiring of every solenoid

valve on the main valve block is secure

and not damaged

Ensure the charger wiring is secure and

not corroded

Ensure the battery posts are secure

and not corroded

Check the battery is secure and not

damaged

Check machine performance and

various limit switches

Check if any connector is loose,

damaged or corroded

Check if the pressure of the hydraulic

system is normal

Check if the lift system hydraulic

pressure is normal

Check if the steering system hydraulic

pressure is normal

Check if the driving system hydraulic

pressure is normal

Check if any oil line or connector is

loose or damaged

Check all hydraulic cylinders for

damage or leaking

Check every hydraulic valve for

damage or leaking

Check if the scissor stack arm oil line

is securely fastened or damaged

Check if the driving oil pipe clip is loose

Check oil level in the hydraulic tank

Replace the hydraulic oil

Loading...

Loading...