English

5

5.1.4 -- Optional ala rm card

Besides the components described for the standard configura-

tion, on the alarm card --- which can be supplied as optional ---

there are relay contacts to have the following alarms sepa-

rated:

1) Compressor high and low pressure

2) High temperature

3) Low temperature

4) Dirty filter alarm (if installed)

5) Fan fault

These alarms cause the unit to stop in the same ways as de-

scribed in the previous paragraph.

For a complete description of the alarms see the encl. Micro-

face manual.

5.1.5 -- Unit in stand--by

The control of the unit in stand---by is completely automatic

thanks to the possibility of connecting the Microface control. A

unit in stand---by starts in the event of an alarm st opping the

main unit; this occurs even if the main unit is switched off or dis-

appears from the system, due to a fault on the cont rol connect-

ing bus. The rotation of the units in stand ---by occurs automati-

cally every 24 hours, so as to allow a homogeneous wear of the

system components.

If the system is connected to the Hiromatic interface, it is pos-

sible to set a different rotation control.

If several units are simultaneously working with the same set

point, the temperature used for the control is the average of the

detected ones; further, in the operation with compressor, the

proportionalband is divided in as many parts as twicethe num-

ber of units belonging to the system,so as to shutthe totalavail-

able refrigerating capacity.

5.2 --- Coolin g and heatin g unit

5.2.1 -- Control logic

The control algorithm is based on a one---step adjustment for

the compressor---aided heating and cooling.

The control manages all its lags in the activation of the com-

pressor, as previously described, so as to guarantee its correct

operation and to make it function as long as possi ble.

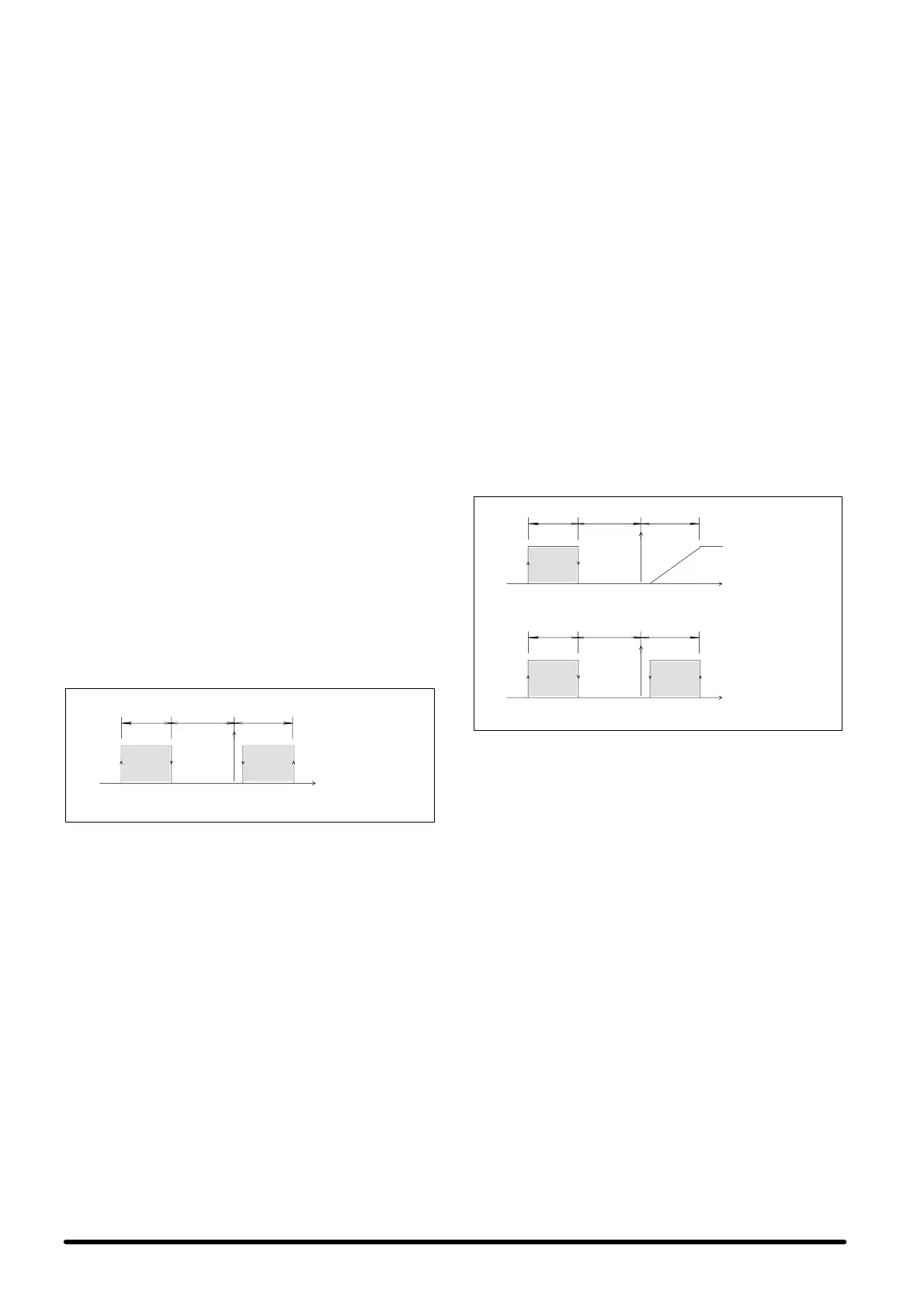

Set Cooling °C

Cooling and

heating unit

Dead band!P@ Pband !P@ Pband

Heating

Fig. J --- Operation of the cooling + heating unit

5.2.2 -- Start--Stop

See Par. 5.1.2.

5.2.3 -- Alarm control

See Par. 5.1.3.

A further general warning is available signalling the following

abnormal condition:

S heater thermostat (reset on the thermostat).

Notes:

S the warning doesn’t cause the unit to stop.

S In case the safety heater thermostat intervenes, the reset

must be carried out on the thermostat, following the same

instructions as before.

5.2.4 -- Optional ala rm card

See Par. 5.1.4.

5.2.5 -- Unit in stand--by

See Par. 5.1.5.

5.3 --- Unit with Freecooling

5.3.1 -- Control logic

This option is also managed by the Microface microprocessor

control, which can be combined with the Hiromatic control to

monitor all the operation parameters of the unit (see the en-

closed manual). The control algorithm is based on a one---step

adjustment for the compressor---aided heating and cooling

and on an adjustment of a Proportional --- Integrative type for

cooling in the Freecooling mode with setting of the set point

and proportional band (P) (Fig. K).

The control manages all its lags in the activation of the com-

pressor, as seen in the two preceding cases, so as to guarantee

its correctoperationand tomake it function as long aspossible.

The Freec ooling mode is activated depending on the differ-

ence (which can be set) between the internal and the external

temperatures. This means that if the difference between the 2

temperatures increases beyond a certain value, the unit auto-

matically passes to the Freecooling function:the compressoris

de---activated and the analog output controls the 3---point ser-

vomotor of the damper. The damper opening is determined as

a function of the difference between the outside and inside

temperatures and as a function of the intake air temperature,

which cannot be lower than a preset safety value.

If the inside temperature exceeds the proportional band by

more than 20% for over 10 minutes, the unit shifts to the com-

pressor---aided cooling and the Freecooling mode remains

de---activated for ½ hour. If the inside temperature exceeds the

proportional band by more than 50% for over 2 minutes, the

Freecooling mode is de---activated for ½ hour, and the unit

shifts to cooling by means of the refrigerating compressor.

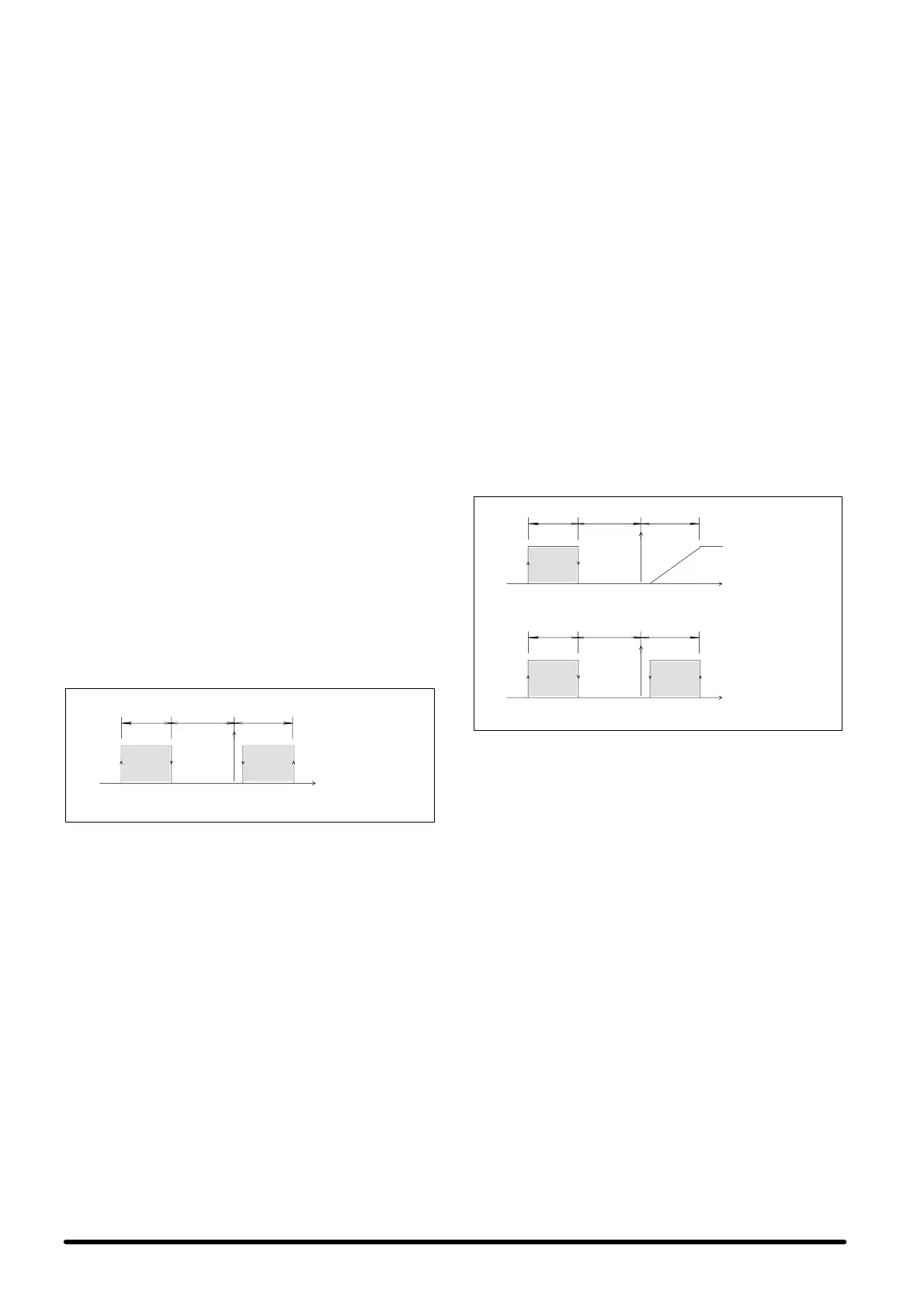

Set

CoolingHeating °C

Freecooling

mode

Compres-

sor

cooling mode

Dead band!P@ Pband !P@ Pband

Set

CoolingHeating °C

Dead band!P@ Pband !P@ Pband

Fig. K --- Operation of compressor, electric heaters and opening of

the Freecooling damper

5.3.2 -- Start--Stop

There are 2 ways for starting or stopping the unit:

a) the digital input of the Microface card;

b) the ON---OFF push button on the Hiromatic interface (op-

tional).

Priority with Hiromatic: a) and b) must be regarded as 2 series

cont acts; the unit can operate only if all contac ts are on.

5.3.3 -- Alarm control

The 2 alarm contacts available on theterminal board of the con-

trol panel can be used in this way:

1) General alarm:

S compressor low pressure

S compressor high pressure (reset on the pressure switch)

S senso r fault

S memory fault

S fan fault

2) General warning --- signalling of various abnormal condi-

tions, among which:

S high temperature

S low temperature

S heater thermostat (reset on the thermostat).

Loading...

Loading...