THE BLUE BOX LT MAKING UP CAT. 5 CABLE WITH RJ45 CONNECTORS 33

LCDBBMUCAT03Sept08

There are two components needed to crimp a Cat. 5 cable:

a “crimper” and a “RJ45 modular connector.” A crimper is

the tool used to make a crimp and seal the cable to the

connector. RJ45 connectors create the interface for a con-

nection and come in four sizes : 4-, 6-, 8-, and 10-position

(position is the placement in the connector that holds a

contact [pin]).

It is important to note, all crimpers and connectors are

not created equal. We have performed many trials to de-

termine a recommended crimper tool and connectors for

our systems; these products will be discussed in a later

section.

Note that no matter what brand of connector or crimp

tool used, just the action of crimping a connector to a

cable can cause it to deform and splay the connections.

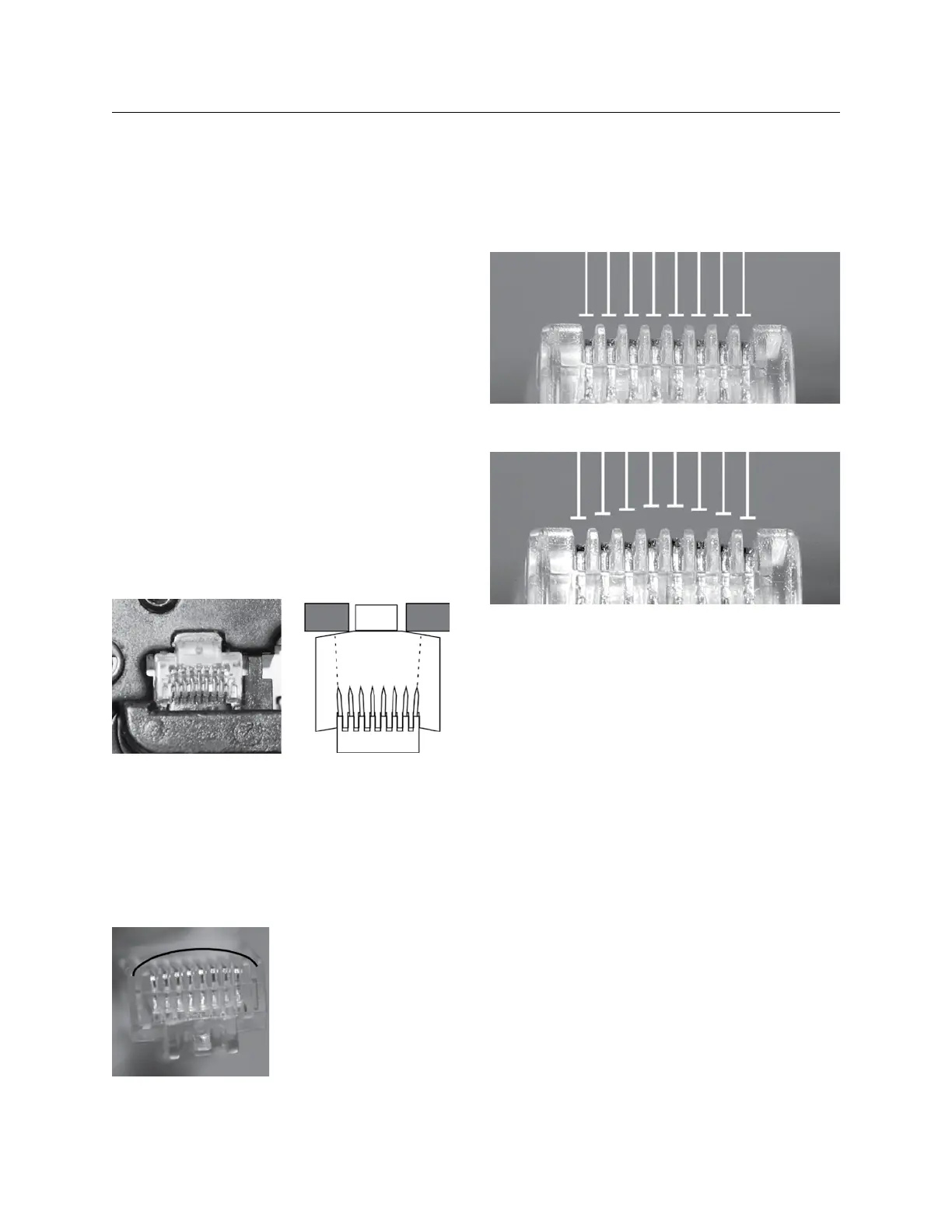

Figure 1.7a illustrates how the crimper head pushes the

contacts down by the same distance but deforms the

plastic case under the pressure; as you see in Figure 1.7b

the contact causes the center crimp to not be adequately

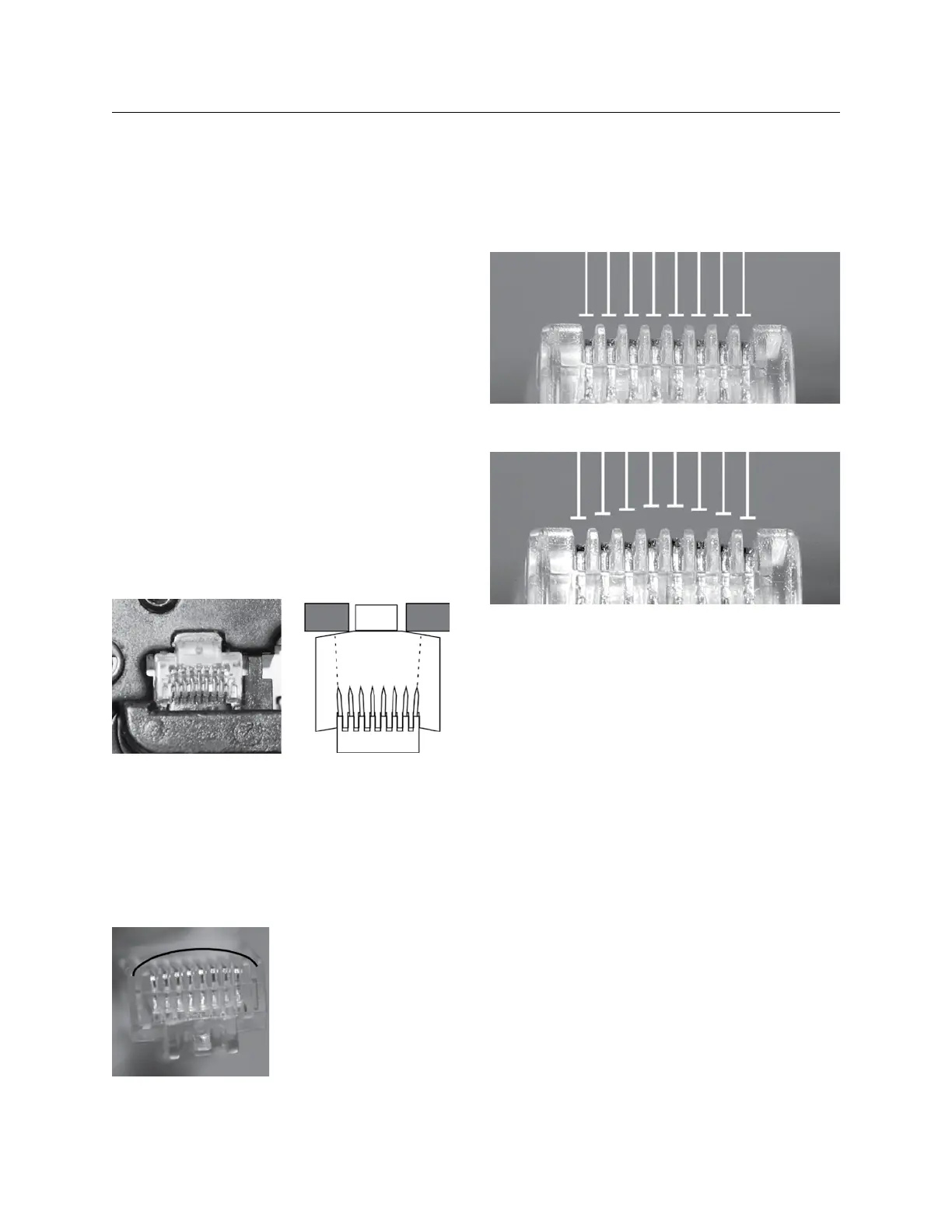

supported or seated. Figure 1.8 shows a crimp after

release; notice how it has a “bowed” appearance.

A bowed crimp is a recipe for

disaster. The two center pins

do not have adequate contact

with the wire. And for the

purpose of LC&D lighting

systems, the two center pins

carry the data! The ONLY

way to completely flush the

REASONS WHY IT’S HARD TO MAkE

GOOD CRIMPS ON Rj45s

center pins is to crimp multiple times (Note: we suggest

5-10 crimps for a successful Cat. 5 cable crimp) (Figure 1.9a

and 1.9b are examples of properly seated and non-properly

seated contacts).

SOLID WIRE IS DUCTILE

The action of pulling a cable side to side does two things: a) pulls

the side wires out of the crimp and/or b) squashes the copper

wire, first one way and then another. The copper “flows” into

a new shape and stays there as if it has been hammered

flat. An example of this pulling occurs unintentionally when a

switch is pushed/forced into a tight space or wall enclosure.

This can result in an “open” connection. This is why we do not

recommend solid wire cable.

THE RIGHT CRIMPING TOOL

Choosing the right crimping tool is the most critical part

of a cable crimping job. All crimping tools do pretty

much the same thing, they force the contacts within the

connectors onto the cable. But as we mentioned earlier,

there is a big difference in the quality of crimps on different

types of crimping tools. In trial testing, we found even the

Figure 1.9a: Contacts are seated properly.

Figure 1.9b: Contacts are not seated properly.

Figure 1.7a

Figure 1.7b

Figure 1.8

Loading...

Loading...