03-09-05 16

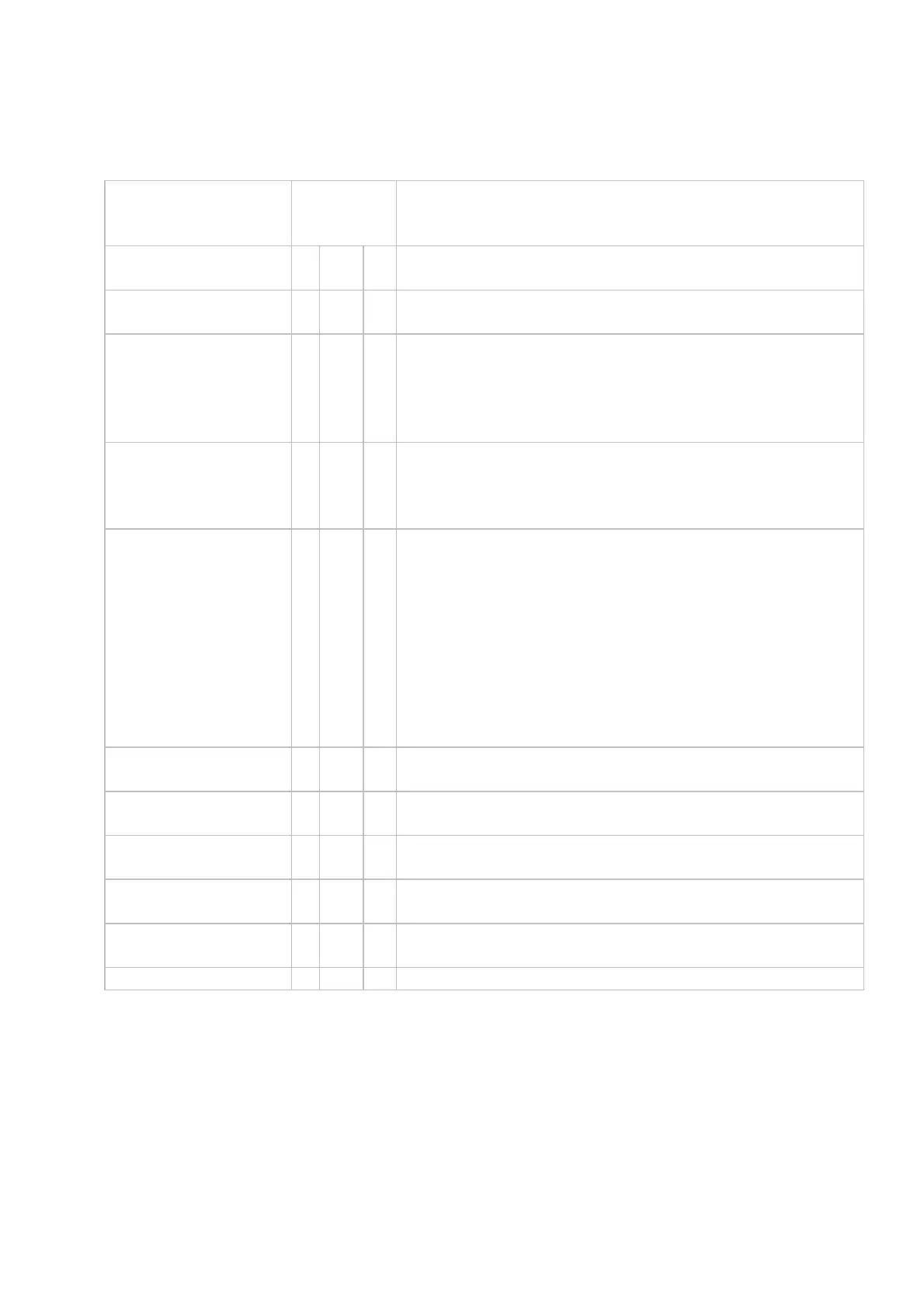

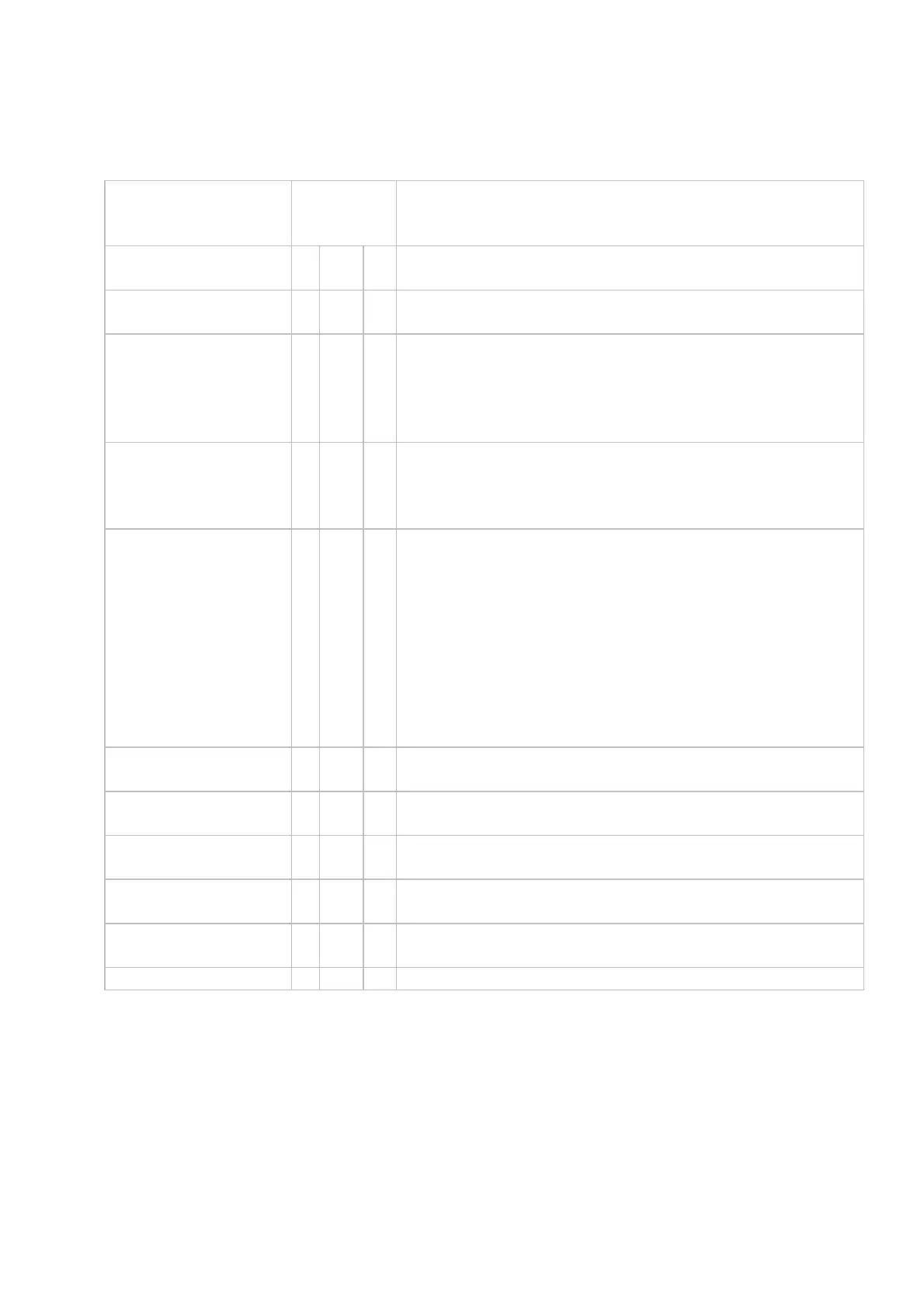

Summary of user precautions regarding laser

For products with a laser safety class 2, 3R or 3B (See text of IEC 60825-1 for

complete precautions, subclause indicated in table):

Requirements

subclause

Class

3B 3R 2

Laser safety

Officer, 10.1

X

For 3R --required only if non visible radiation

Remote

interlock, 10.2

X

Connect to room or door circuits. Pin no 14 (LASER ON) of

the SLS connector can be used for this purpose.

Key control

10.3

X

Remove key when not in use.

Key control is provided when power supply is delivered by

LMI Technologies. To conform to safety requirements a key

control must be installed. Use pin no 15 (+24 VDC) of the

SLS connector to /connect/disconnect the power of the SLS.

Beam

attenuator

(Laser shutter)

10.4

X

When in use prevents inadvertent exposure.

Provided by LMI Technologies and permanently mounted

on the front of the sensor. See chapter 2, figure 1.

Emission

indicator device

X (X)

Indicates that the laser is energized. Required for 3R only if

nonvisible laser.

See chapter 2, figure 1.

Provided by LMI Technologies and permanently mounted

on the side of the sensor. One of the LEDs is always lit.

• The yellow LED is lit when the sensor signals Invalid,

e.g. no object inside the measurement range, too little

light scattered back to the detector, to much light

scattered back to the detector.

• The green LED is lit when the measurement is Valid

Warning signs,

10.5

X

Follow precautions on warning signs.

Beam path,

10.6

X X

Terminate beam at the end of its useful length.

Specular

reflection, 10.7

X X

Prevent unintentional reflections

Eye protection,

10.8

X

Required if engineering and administrative procedures not

practicable and MPE exceeded.

Protective

clothing, 10.9

X

Not required

Training, 10.10

X X

Required for all operator and maintenance personnel.

Emission delay

LMI Technology’s sensors can be equipped with two different types of emission

delay. One (called Laser ON delay) will always cause a short delay every time

the laser control signal is turned on, before the laser actually starts emitting laser

light. The other type (called Power ON delay) will only cause a delay when the

sensor is first powered up. All subsequent cycling of the laser control signal will

control the laser without any delays. See quality record.

Loading...

Loading...