03-09-05 35

Unstable thickness reading

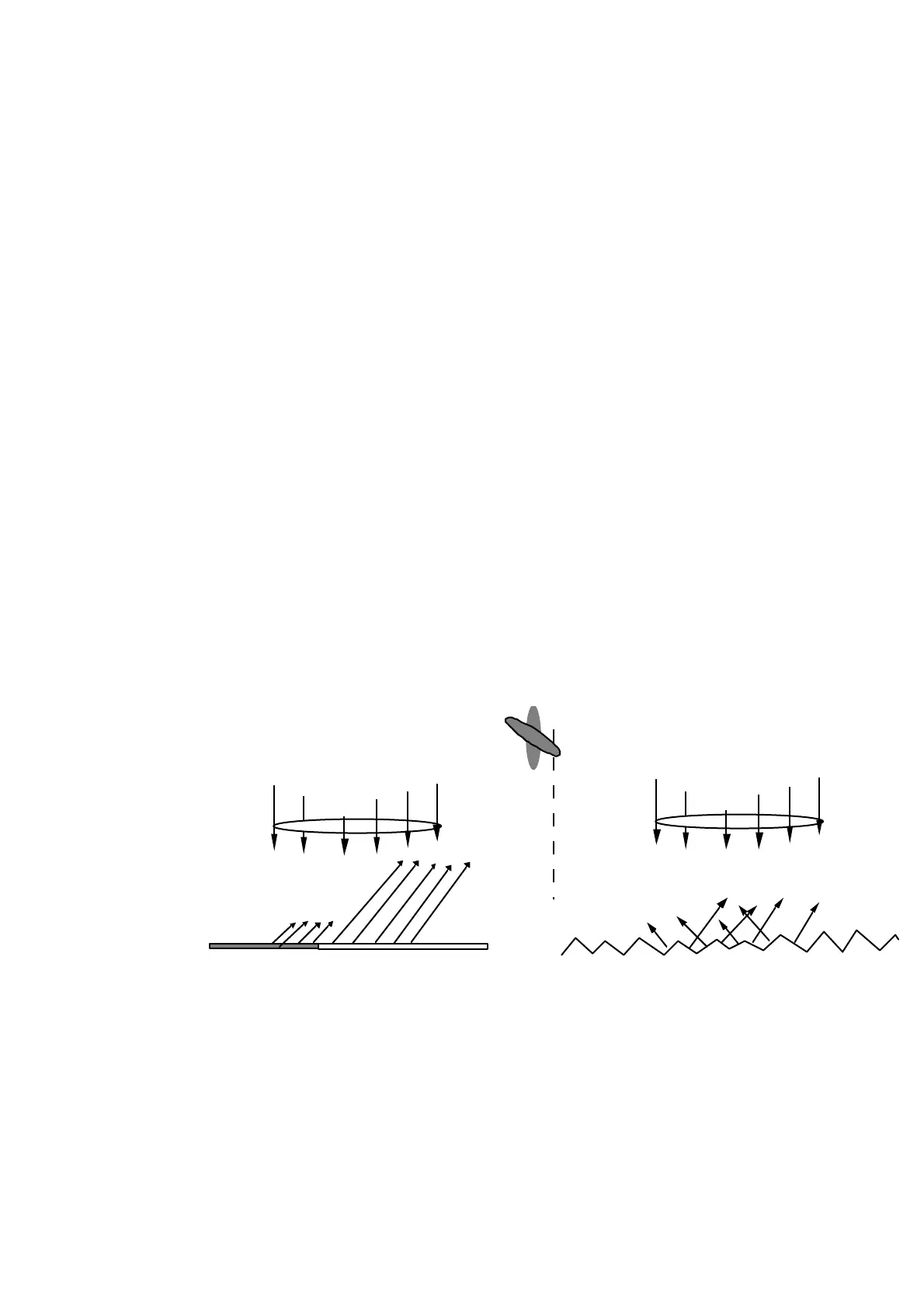

1 In the case of a dual sensor system, the sensors will receive not only

reflected light but also the transmitted light from ”the opposite” SLS

sensor. Since they are working at nearly the same frequency, they will

interfere with each other. The output from the system will contain a low

frequency component (~1 Hz) even if the set up is in steady state. This is

an important phenomenon that has to be considered in all dual

applications. Note that special designed SLS sensors can be ordered to

avoid this phenomenon.

Advise

2 Single sensor thickness measurement using a mechanical reference.

Offset compensation for penetration can be useful if the material is

homogeneous.

3 Dual sensor thickness measurement on semitransparent materials.

Use SLS sensors designed for semitransparent materials.

Surface texture. Static texture error

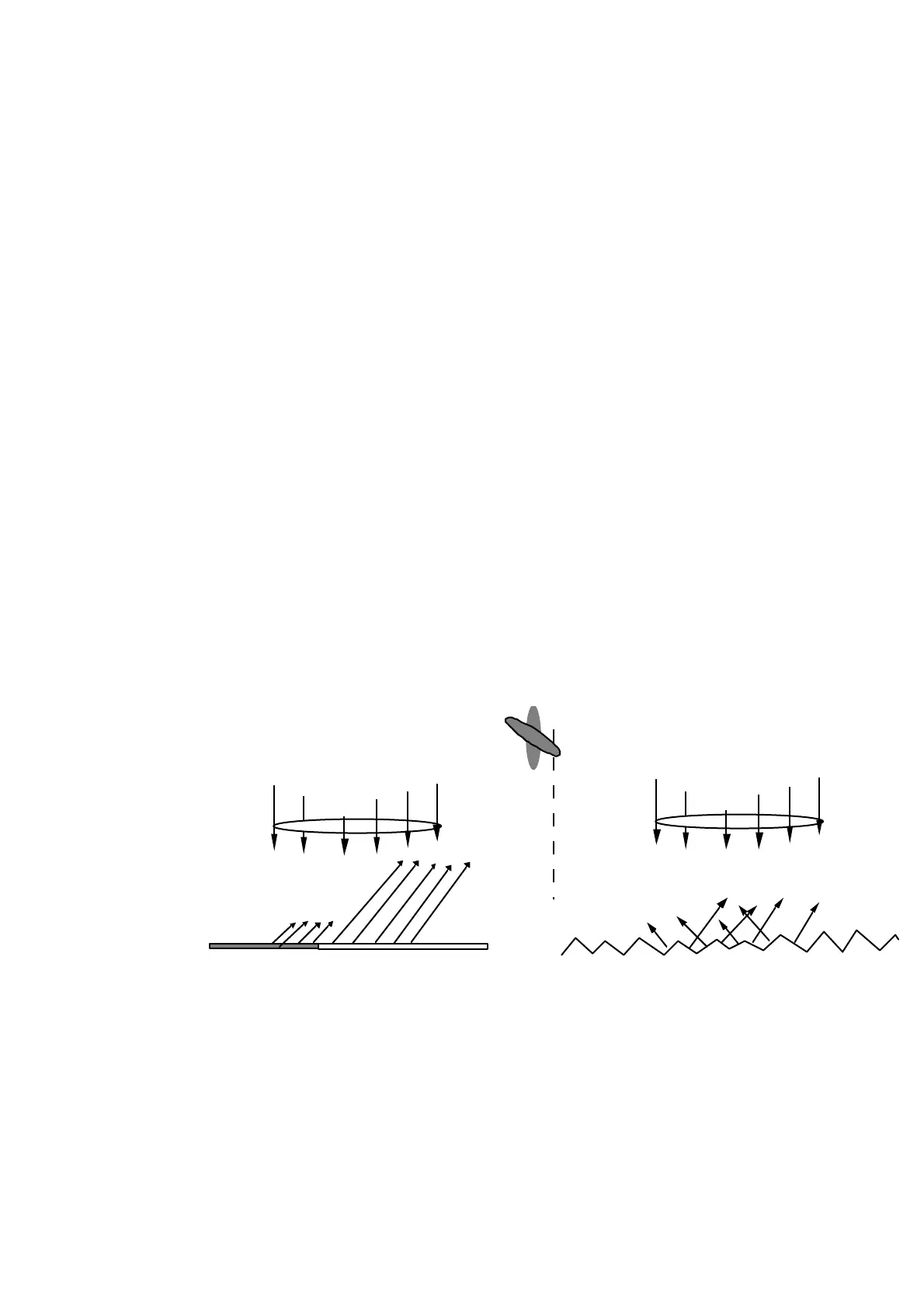

A basic statement to take care of is that the light spot produced on the target

covers a certain area and the SLS sensor will respond to the center of gravity of

the image of that spot on the detector. If the spot covers an area that gives an

irregular amount of scattered light in the direction of the receiving optics, the SLS

sensor reads a position of the surface below or above the true surface.

White surface

Black surface

Rolled steel

Receiving

lense

Laser

beam

Laser

beam

Figure 28: Reflection depending on target material

The change in the position output depends on the orientation of the sensor. The

magnitude and the duration in length depend on the size of the laser spot. As a

general rule the spot must be as small as possible. An example of output from the

SLS sensor is shown in the figure below.

Note that if the SLS sensor is rotated 90 degrees to the orientation indicated, no

error spikes occurs.

Loading...

Loading...