03-09-05 30

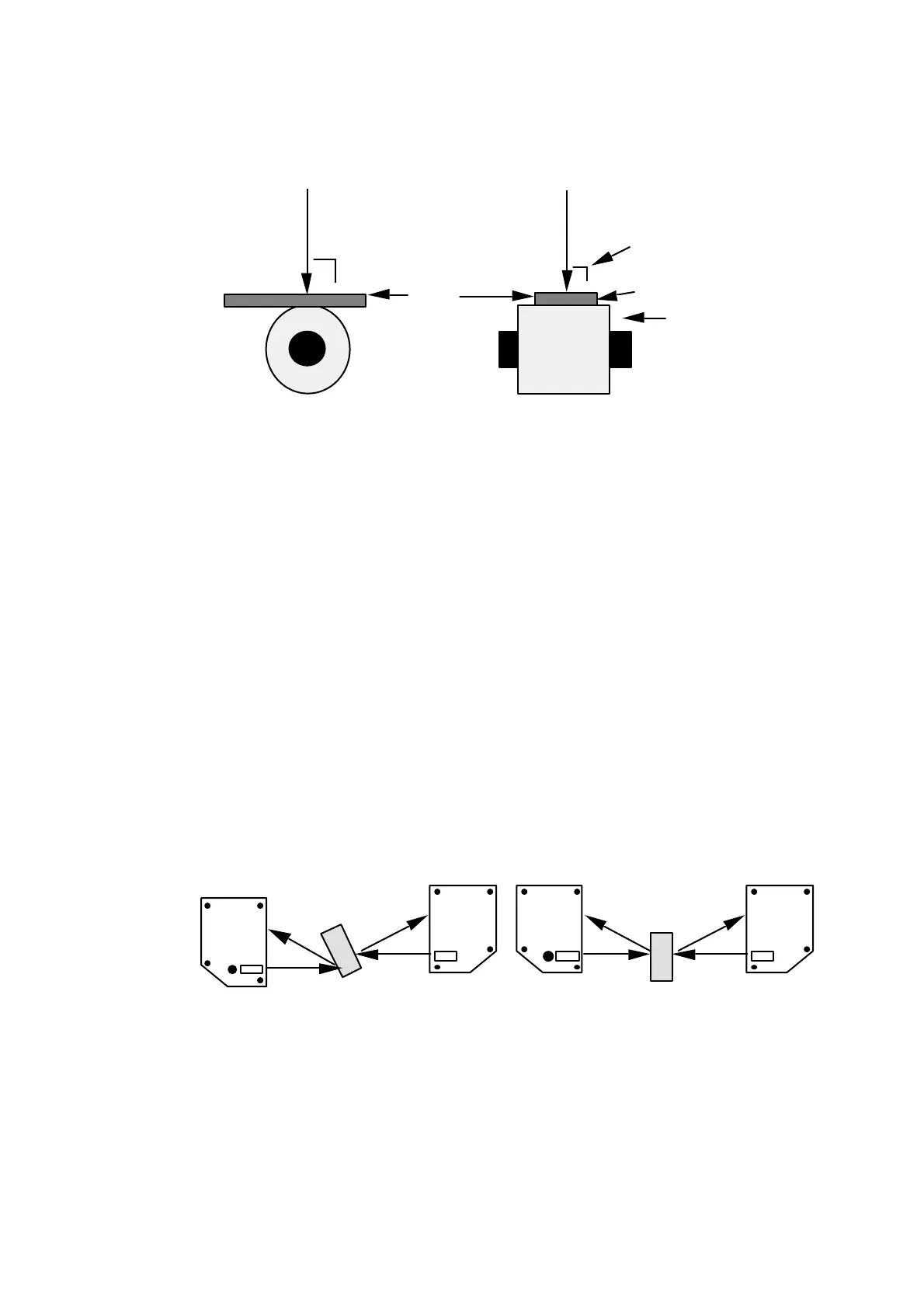

For a single SLS sensor system

The distance between the SLS sensor and the reference plane must not be

changed.

2

3

4

Target

Reference

roller

Reference

roller

11

Figure 20: Measurement against the reference plane

1. Laser beam

2. If the incoming laser beam is not perpendicular to the measured surface,

compensation for the angle may be necessary.

3. Good contact between the reference surface and the measured material is

important.

4. Eccentricity of a reference roll may cause variation in the thickness value.

Keeping track of the roll while performing multiple calibrations may solve

this problem.

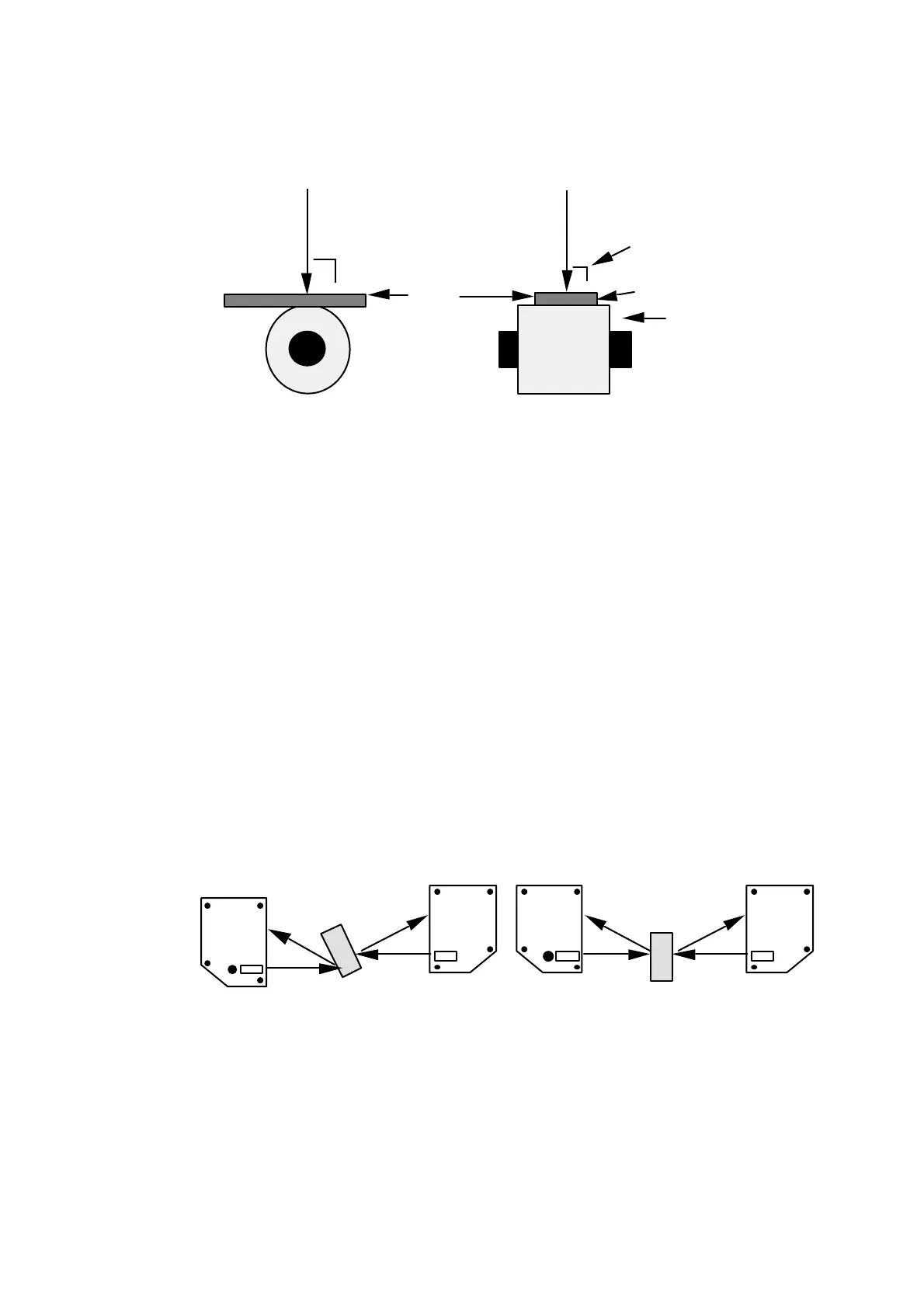

For a dual SLS sensor system

The distance between the two SLS sensors must not be changed, between

calibration and measurement.

The accuracy of a dual SLS sensor system for thickness measurement is highly

dependent on laser beam adjustment of the two sensors. It is necessary to have the

two laser beams concentric through the entire measurement range. In the left

figure below, the thickness will decrease when the measured object is tilted as in

the figure and increase (more than correct) when tilted the other way. In the right

figure the thickness of the measured object will increase for any tilt angle.

WRONG

CORRECT

SLS5000

SLS5000

SLS5000

SLS5000

Figure 21: Installation example, dual sensor thickness measurement

• Useful equipment:

• IR-viewer.

• Piece of cardboard paper (about 0.5 x 100 x 100 mm, preferably blue).

• Piece of non-transparent material (about 5 x 100 x 100 mm, with even

thickness).

• Horizontal spirit level.

Loading...

Loading...