03-09-05 29

Mechanical installation.

The SLS sensor must be mounted rigidly in such a way that neither thermal

expansion of the fixture nor external forces may influence its position. Otherwise

the accuracy of the system will be affected and frequent re calibrations of the

system may be necessary. Calibrate the system as often as possible to avoid

influence of mechanical fixture drift due to time and temperature.

Make sure that the optical path is not obstructed.

•1 It is possible during installation that unintentional

exposure to laser light may occur take extra care not

to look into the laser aperture of the SLS sensor

unless you are certain that the laser beam is turned

off. Tools that are used during installation may give

mirror like reflections.

•2 If possible wear protective goggles.

•3 The laser beam of the SLS sensor cannot burn skin.

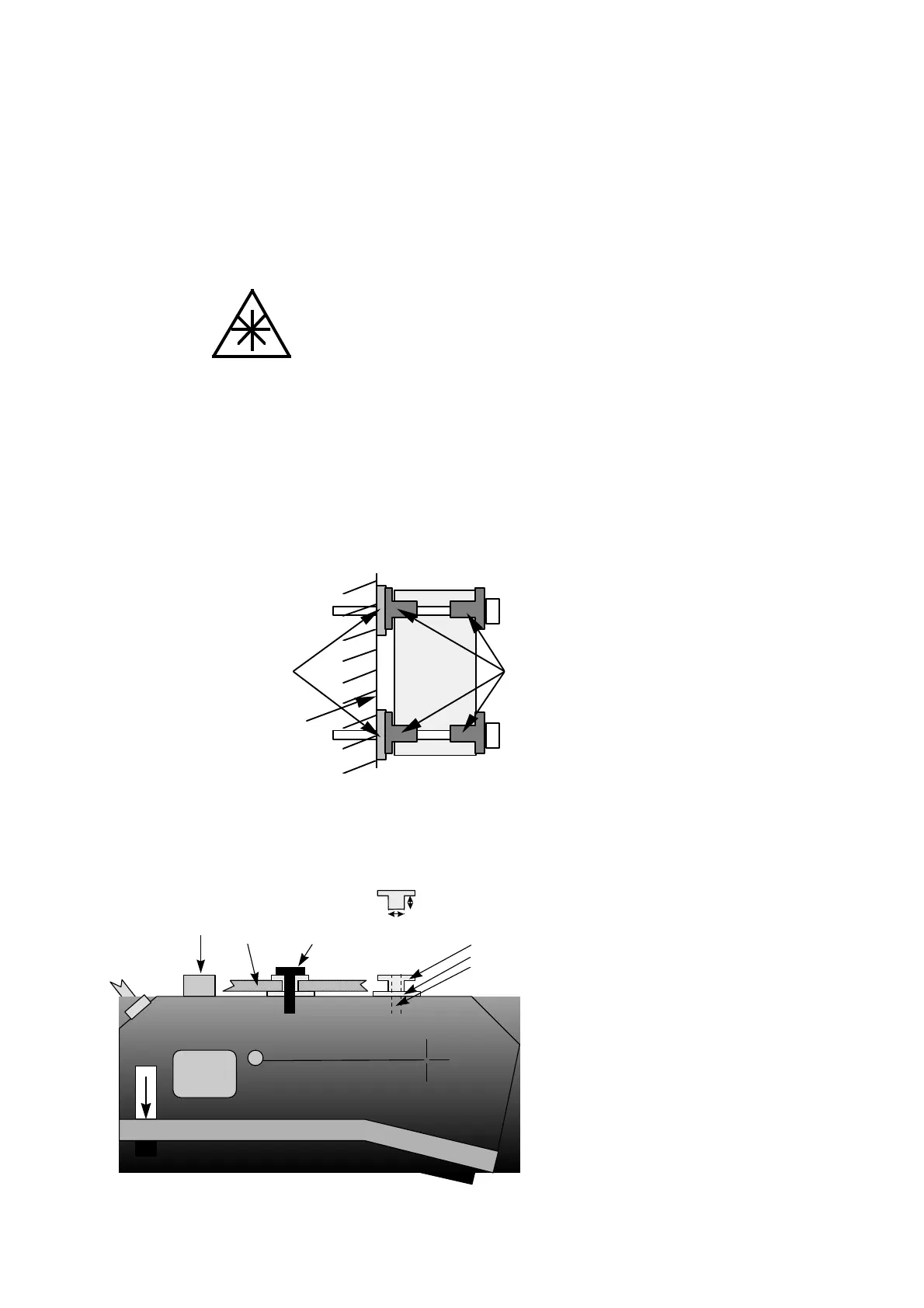

Eight plastic mounting washers are enclosed in the delivery. These washers may

be used to electrically isolate the sensor from its mounting surface, see figure

below.

M6 mounting

bolts

Isolation

washers

Washers

Mounting surface

Drill diam.

10.5 - 11.0 mm

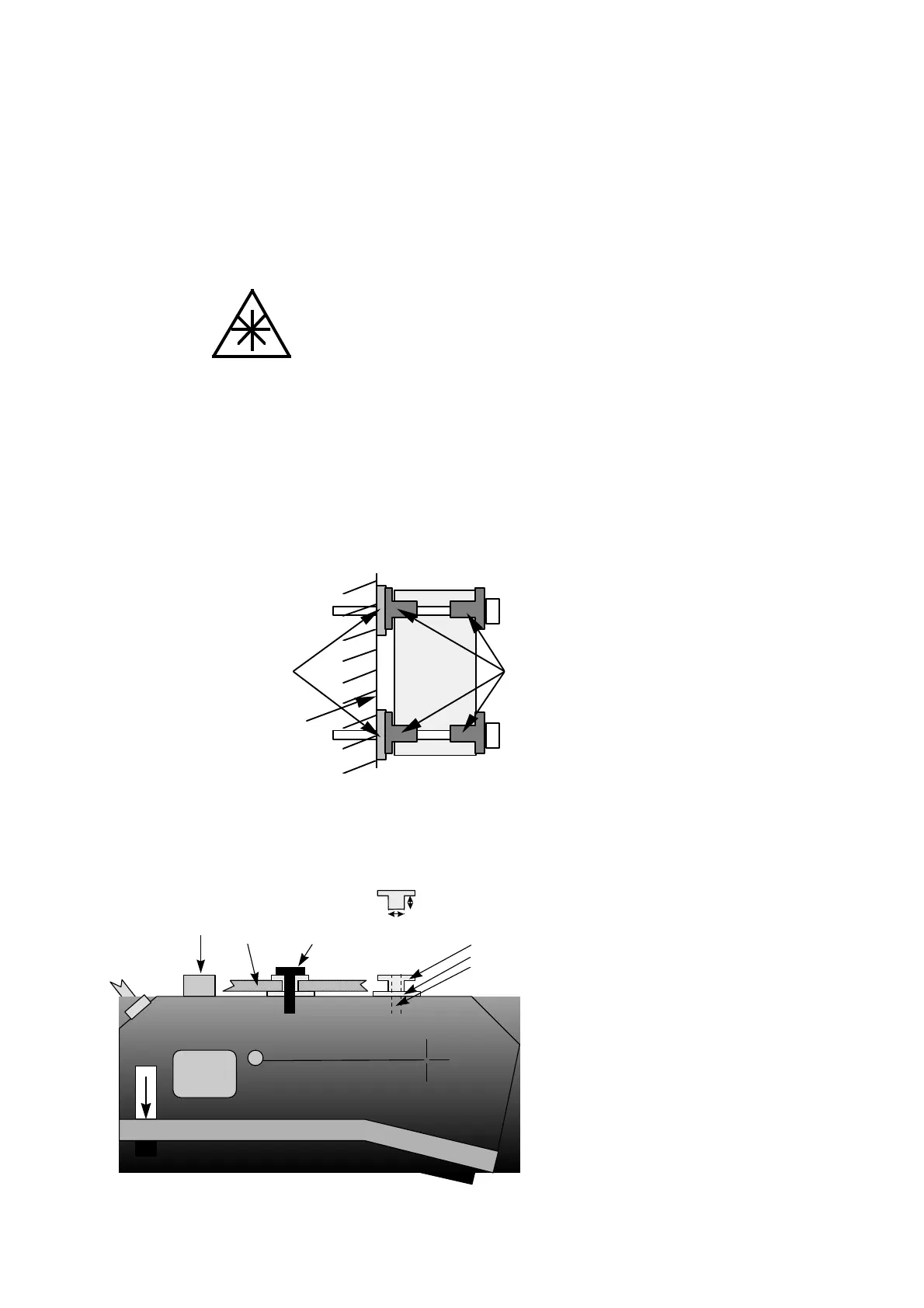

Mounting Surface

Selcom

LASER MEASUREMENTS

SLS 6000

DANGER

Laser

Class 3B

Air purge inlet

Isolation washer (4x)

Washer (4x)

Mounting Holes M8(4x)

Mounting plate

Bolt (M8)

7,0 mm

Loading...

Loading...