03-09-05 32

not occur when using special designed sensors for semi transparent materials.

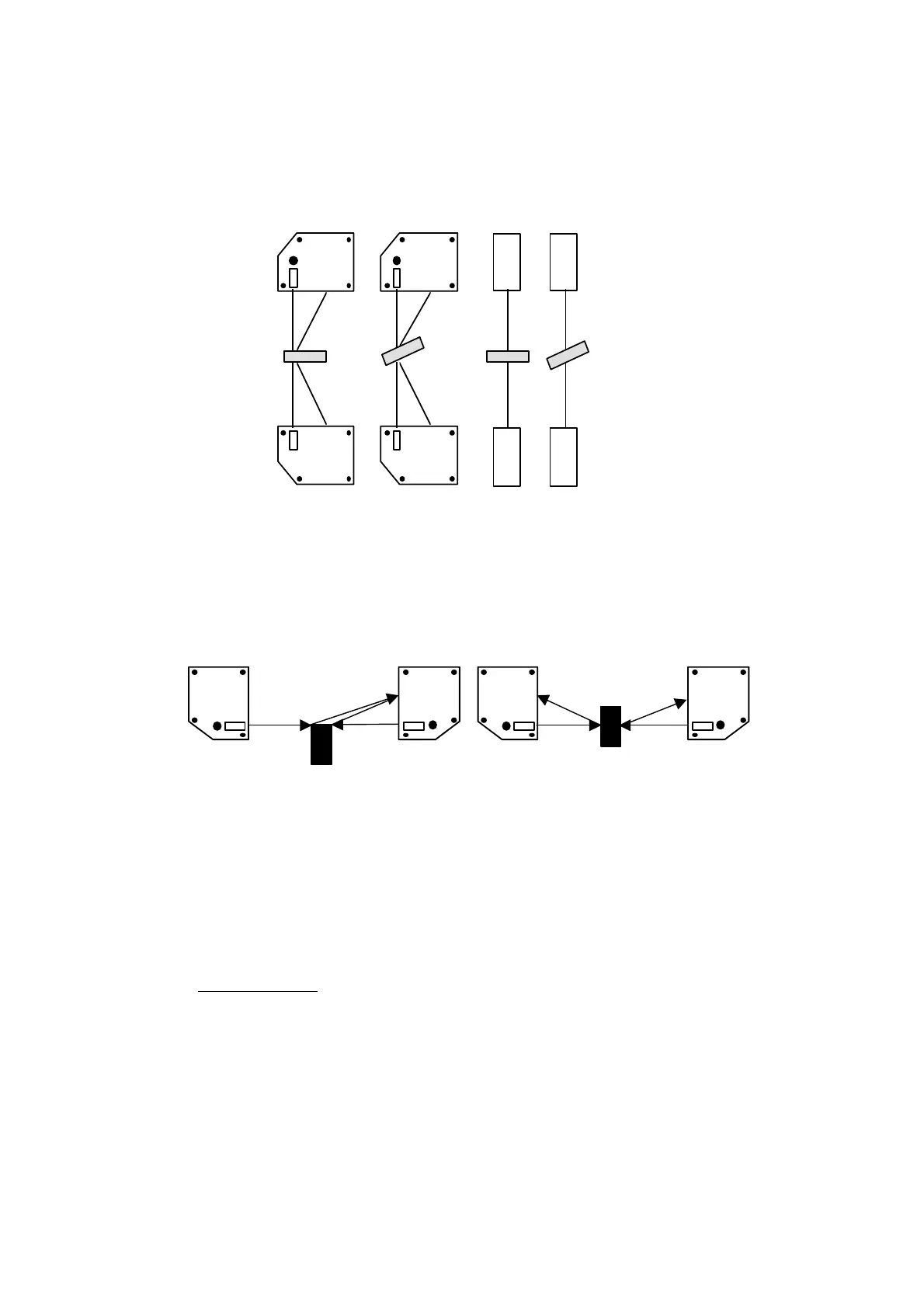

4. Remove the cover over the receiver opening. Put the piece of non-transparent

material in the measurement range. Try to keep it as perpendicular to the laser

beams as possible. If the sensors are correctly aligned you will note an

increase of the thickness when you tilt the plate. A decrease of the thickness

value is an indication that the sensors are misaligned.

Sensor 2

Sensor 1

Sensor 2

Sensor 1

Increase of

thickness

Increase of

thickness

Figure 23: Illustration of item 4 above.

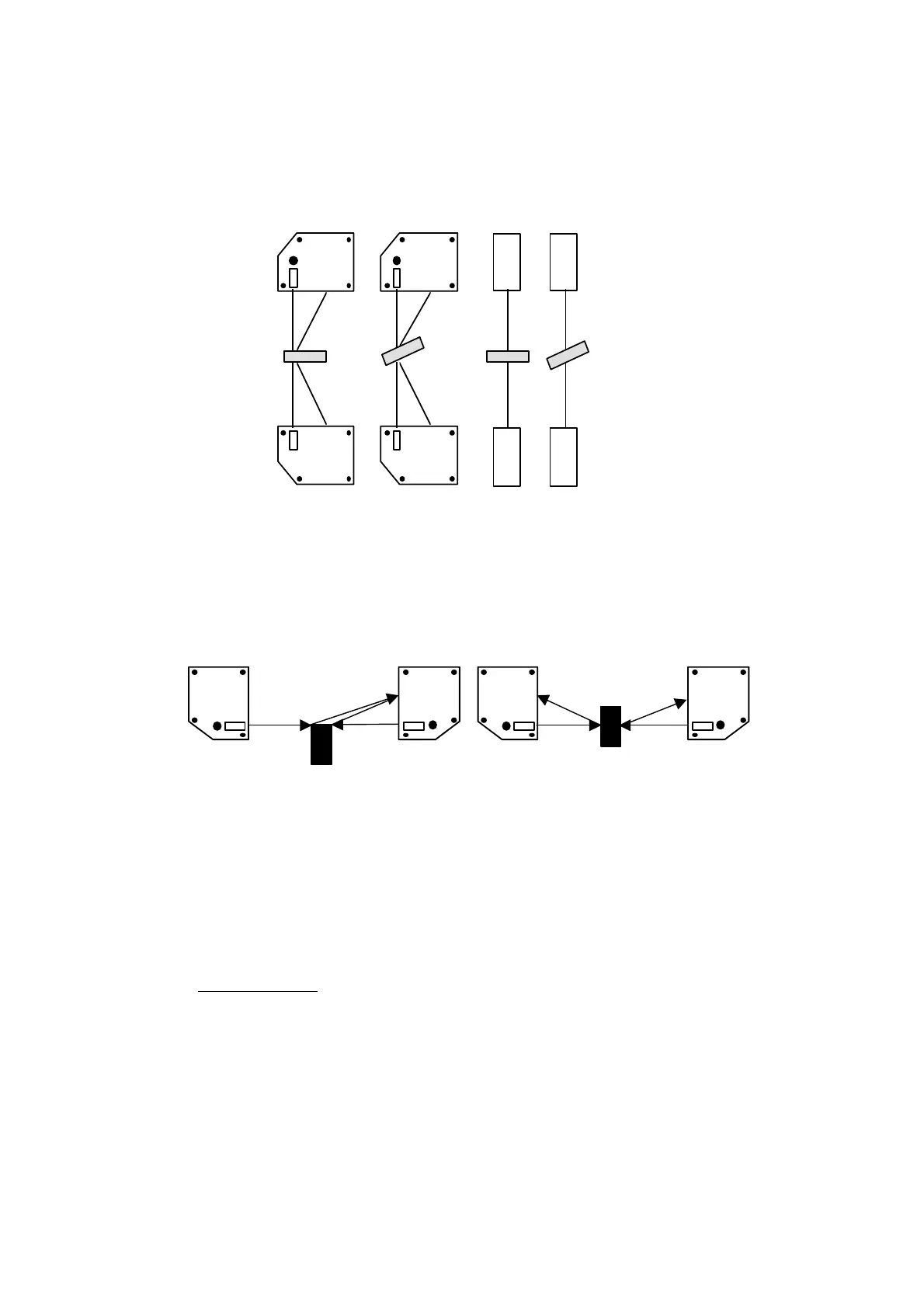

Avoid set-ups where the two sensors can see each other when they are supposed

to measure. A set-up as described in the left figure will produce a variation in the

output value at approximately 1 Hz. See semitransparent materials.

SLS5000

SLS5000

SLS5000

SLS5000

WRONG CORRECT

Figure 24: Dual sensor thickness measurement

Hints for measurements

The SLS sensor is designed to give a true and dependable measurement for a vast

range of materials, surfaces and speed of target/surface.

Sensor features:

1 High speed of light power control.

2 Dynamic range of light power output extremely wide

3 Bandwidth of position data from up to 2 kHz.

4 Sampling rate 16 000 times per second.

5 Small laser spot.

Some materials or surfaces requires some considerations and advises to get the

best possible performance.

The target characteristics can be structured into:

1. Material.

Loading...

Loading...