03-09-05 36

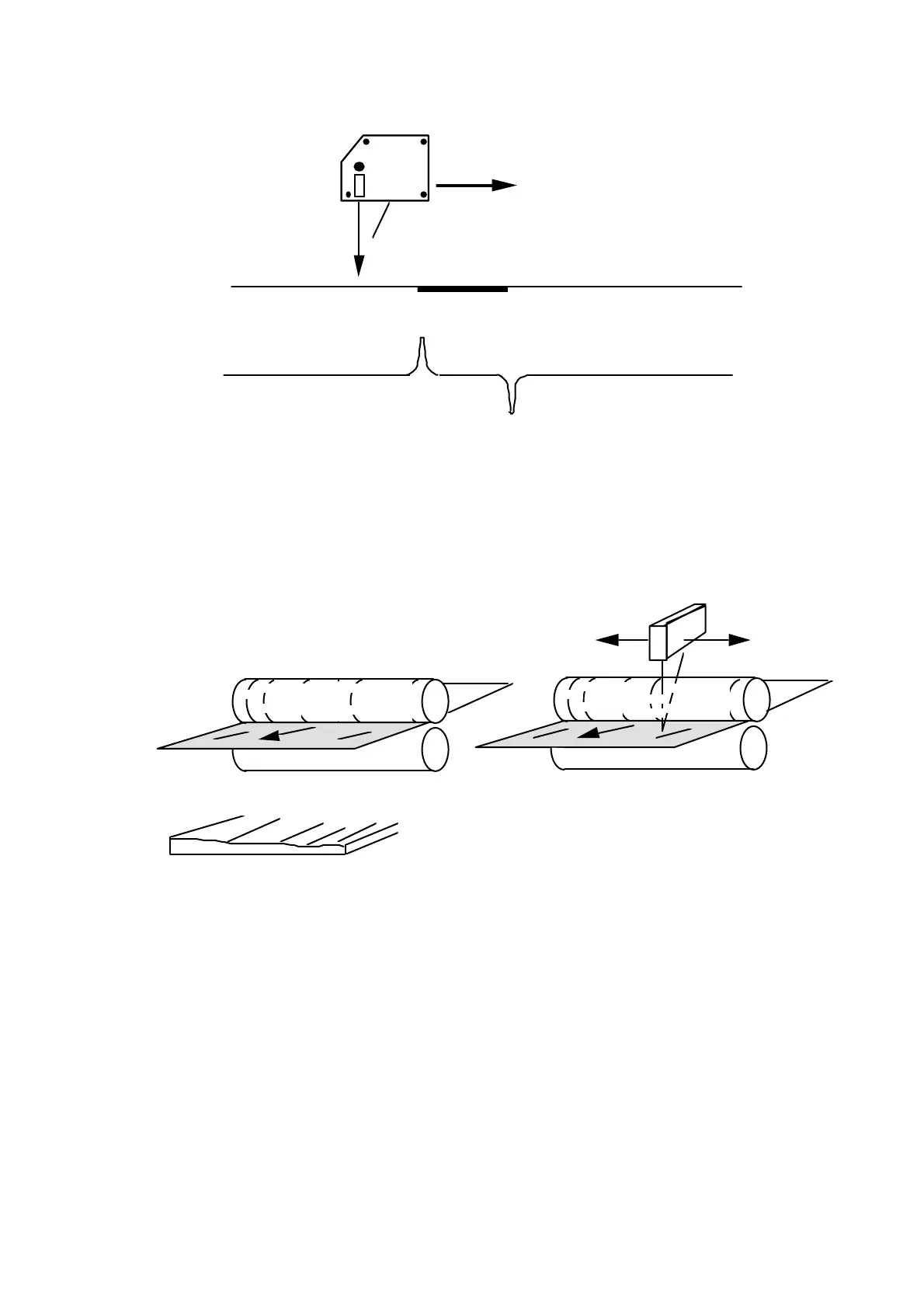

Scan

Position

output

Black strip/spot

SLS5000SLS5000

Figure 29: Example of output from the SLS sensor

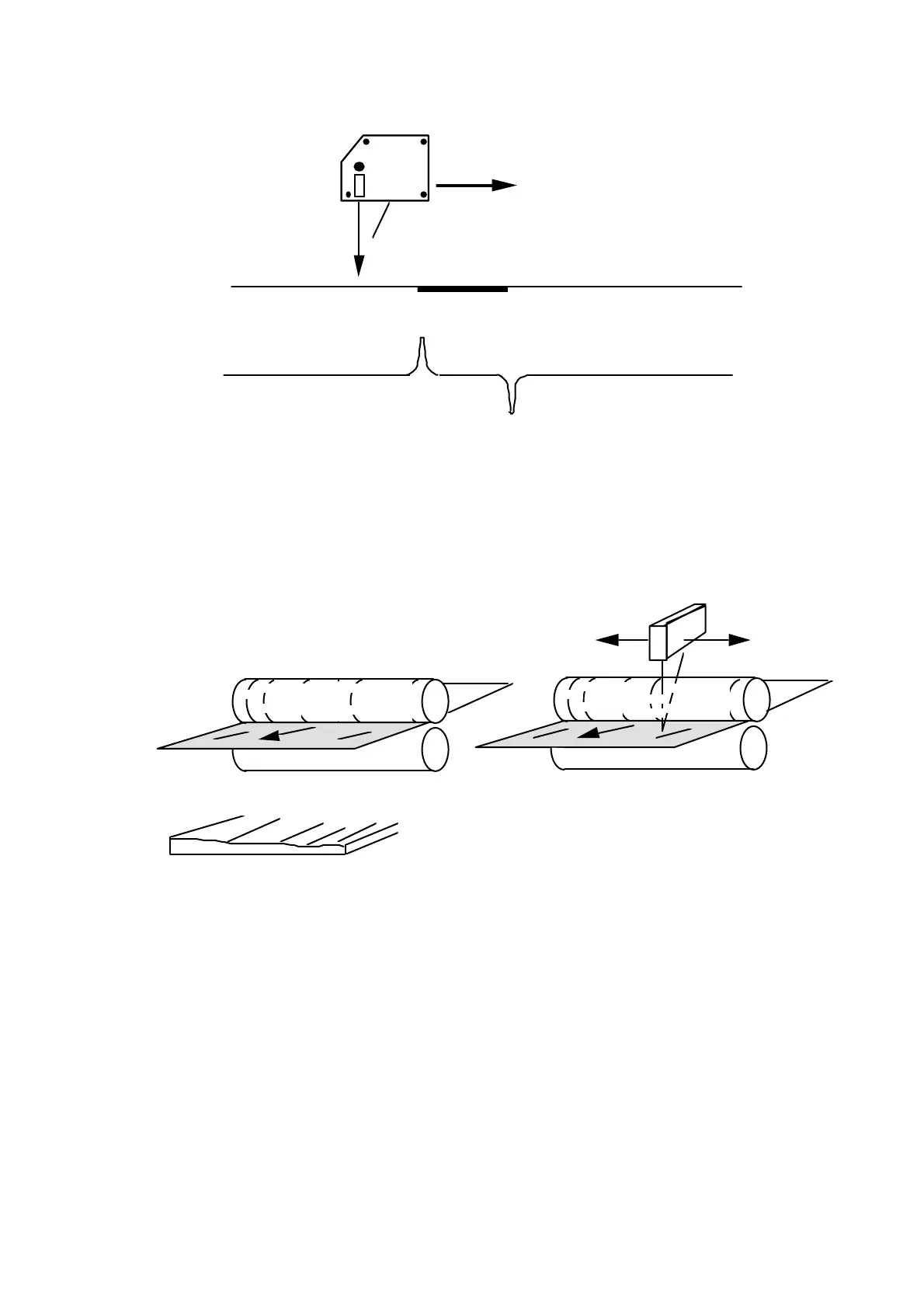

Surfaces with a regular pattern from machining (e.g. rolling marks or from

grinding) will cause a uniform scattered reflection. This will result as a static error

that varies depending on where on the machining marks the center of gravity of

the light spot is located. Scanning across the marks and averaging the measured

data can eliminate this error.

FIGURE 1A

FIGURE 1B

FIGURE 2

Figure 30:

Fig. 1 A The regular surface is often produced in a rolling mill and looks like

a rib mark structure along the strip.

Fig. 1 B In other words regular thickness variations across the strip.

Fig. 2

The SLS sensor should be mounted parallel to the ”ribs” and with a

scanning direction across the direction of travel.

Advise

1 If possible orient the optical triangle parallel to surface irregularities.

2 If possible try to calibrate by letting the laser spot scan over a distance

(e.g. 10 mm) of the surface, to eliminate static texture error.

3 Calculate an average over distance when measuring.

Loading...

Loading...