03-09-05 34

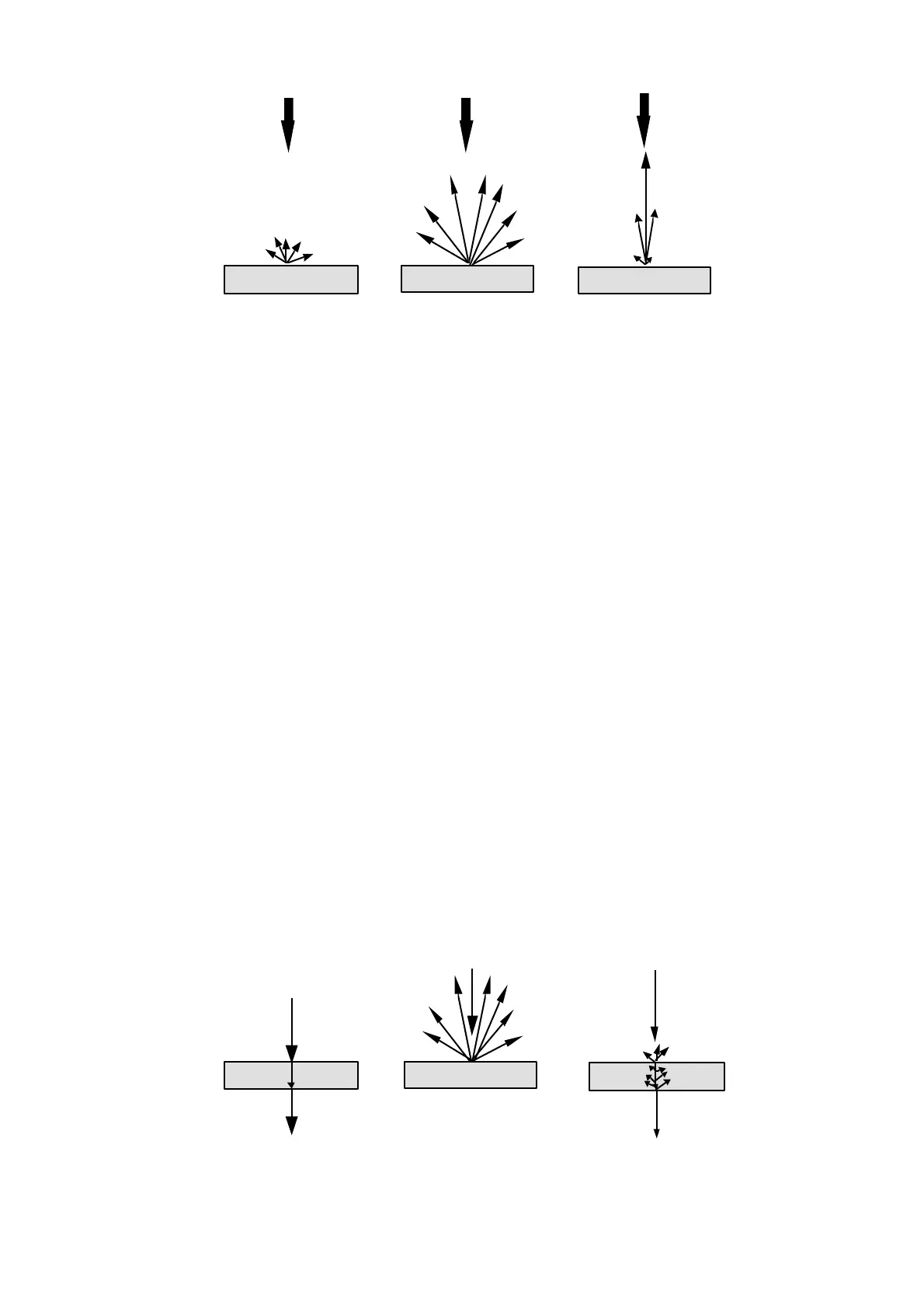

Black material General group

Shiny material

Figure 26: Illustration of reflection

Advise For extremely shiny materials like molten metal (magnesium with

protection gas or coated zinc plates very close to the bath) without any skin or

oxide on the surface it may be necessary to tilt the SLS sensor somewhat to get

enough light in the direction of the receiving optics consult LMI Technologies.

Note that some material ages optically, e.g. car paint or uncured rubber. Compare

an absolutely fresh sample from the extruder measured immediately and after 15

minutes a great difference will be noticeable.

5.1.1.4 Transparent materials

Transparent materials cannot be measured since no light is scattered on the

surface (e.g. glass). Transparent materials like coolant oil or water on a surface

will add roughly half the thickness of the oil or water layer (given by the

refraction index) to the thickness or position data.

Advise: The compensation for the layer thickness is roughly 50% of the actual

transparent layer thickness. (For oil and water layers).

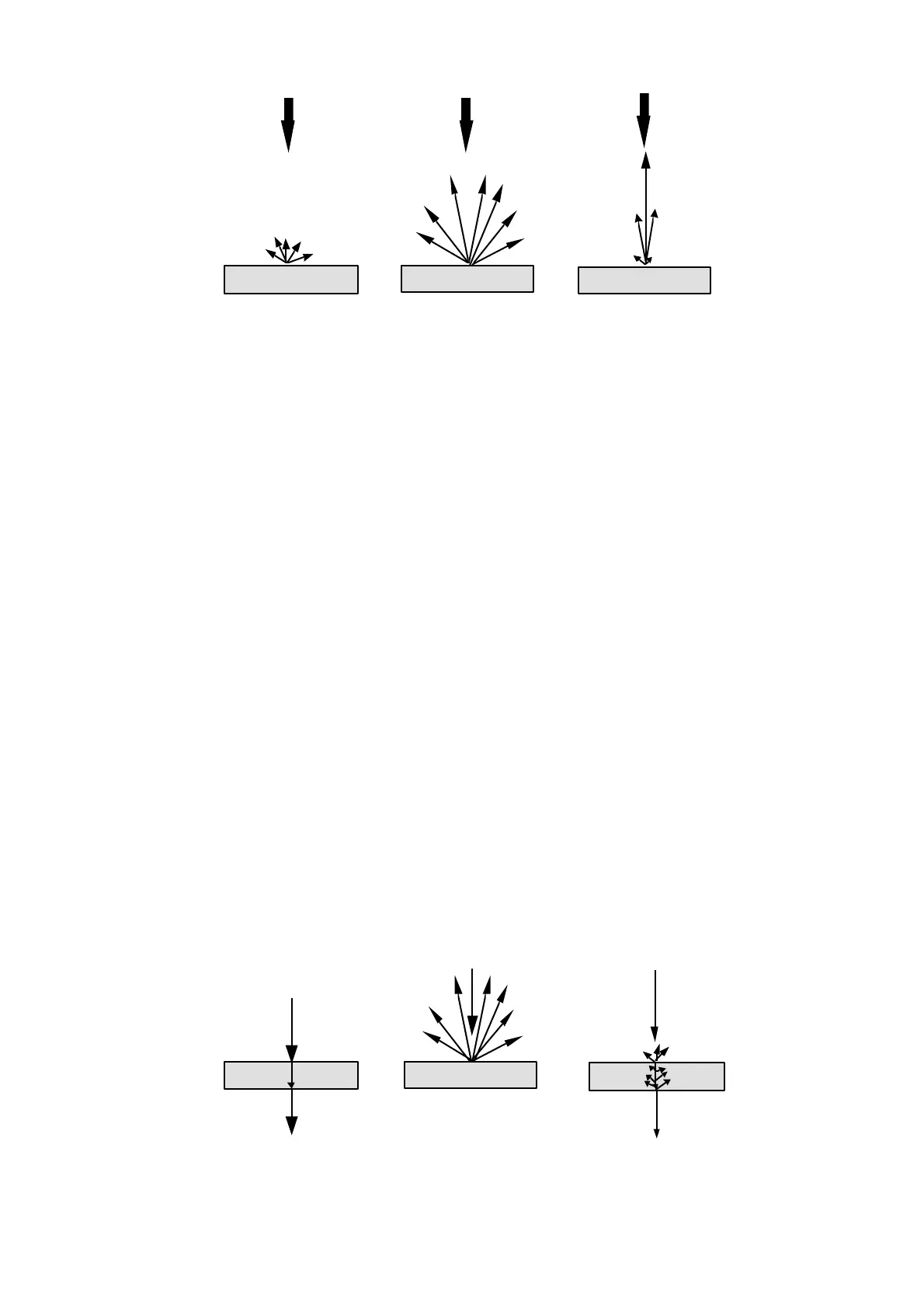

5.1.1.5 Semitransparent materials

The semitransparent material will scatter enough light to produce a stable

measurement, but there will also be a penetration of light into the material and a

contribution from internal reflections (as well as background reflections). The

result is a position reading that is below the actual surface. The ”offset” value

depends on the degree of transparency. In many situations the offset is small and

constant and can be calibrated for.

A method to measure this offset is to stick a thin strip of adhesive paper to the

surface and scan the material (the thickness of a paper is approximately 0.1 mm).

Transparent

Reflective

Semi transparent

Figure 27: Light behaviour on transmission material

Loading...

Loading...