27

Material drying

Generally, once the wood is

sawn it must be dried.

It is possible to use undried

wood in some construction,

but only keeping in mind a 7%

shrinkage in width and height.

While most wood shrinks some

0.4% in length, this amount can

usually be ignored. In order

to avoid rot, you should not

enclose undried wood in a way

that makes it hard for air to

circulate. One further tip is not to

drive two nails into undried wood

next to each other as the board

will probably crack in the middle

when it dries out. Drive one nail

and wait with the second until

the wood has dried.

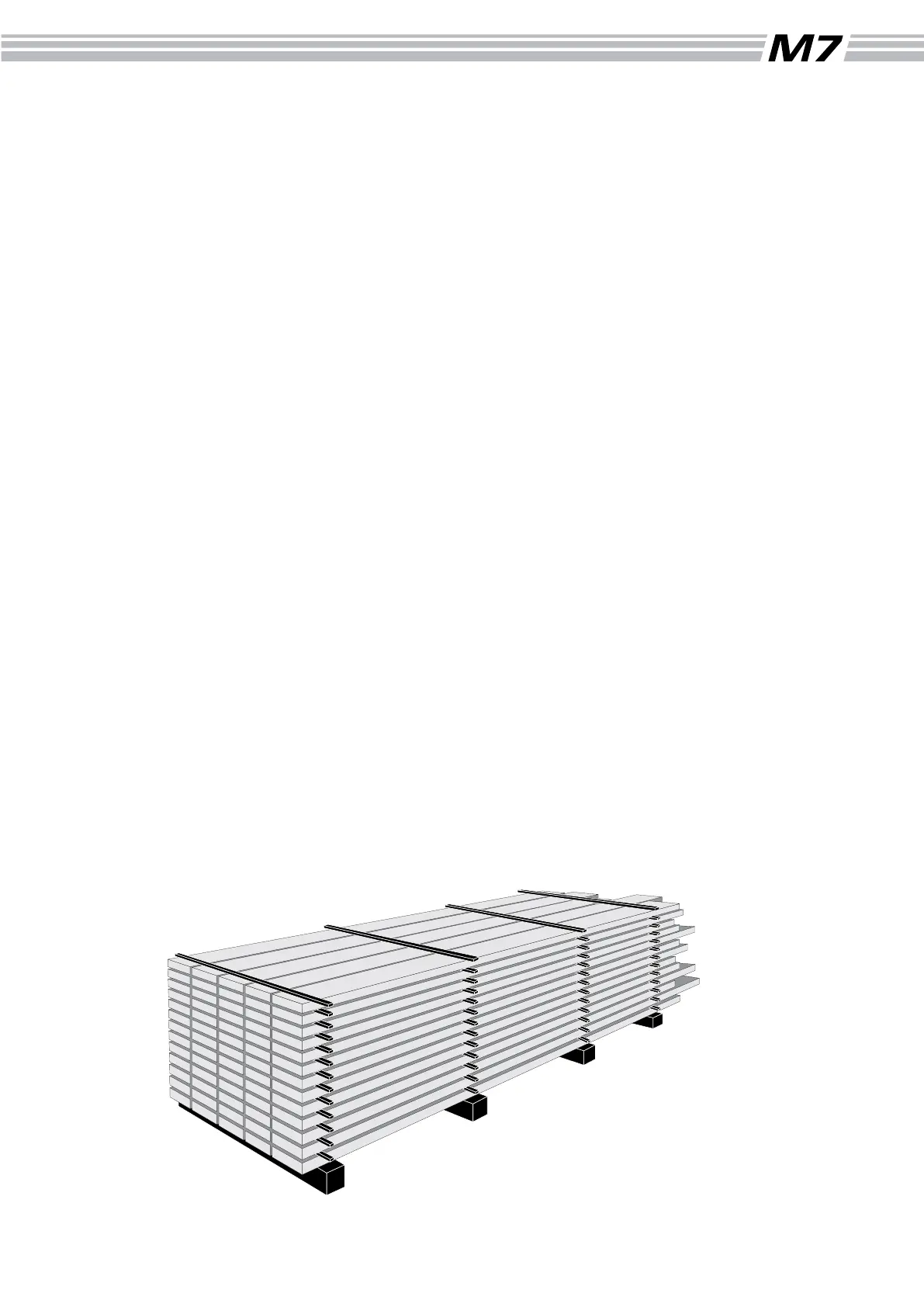

be the same thickness (1x1”

or 1x2”) and dry. You can get

material for these by making an

extra cut when trimming your

boards.

Place your rst row of boards on

the support logs, leaving about

an inch between them. Then

place a spacer on the boards

above each support log. It is

important to place the spacers

exactly over each other to keep

the boards from warping or

bending.

The higher you pile the boards,

the better pressure there is on

the lower boards. Place roong

or some material over the top,

but leave the sides and ends

open. Put a weight of some

sort on top of the upper row to

put pressure on those planks

as well.

If the wood is to be used for ne

carpentry it ought to be stored in

a heated facility several weeks

before use, or be dried in a kiln

or other kind of wood drier.

One example when you ought to

use undried wood is building log

structures. In such a situation,

a heavy wall is a plus, as is

the possibility that the logs still

can be shaped when they are

pressed against each other.

In most cases, however, the

wood must be dried. If this is not

done, there is a danger it will be

damaged by dry or fungal rot.

The best time for outdoor drying

is in the spring. At that time the

relative humidity in the air is

comparably low meaning that

the wood will dry quicker.

Cut some supportive blocks

(5x 5”) in t he l eng t h t hat

corresponds to the width of

your pile. Place these at regular

intervals as shown below on dry,

level ground free of growth. The

spacing should not exceed 1 m

(app. 1 yd) and should lie level

and in line with each other.

Cut spacers or drying sticks

in the same length as the

supportive blocks. They should

Begin by halving and quartering

the log. When sawing the boards

out of the quarters, you turn

the log 90° between each cut.

Sometimes it is best to cut from

below as this allows you to raise

the log beds to the same height

throughout.

Loading...

Loading...