Starting up

- 39 -

01.21 909.2669.9-02

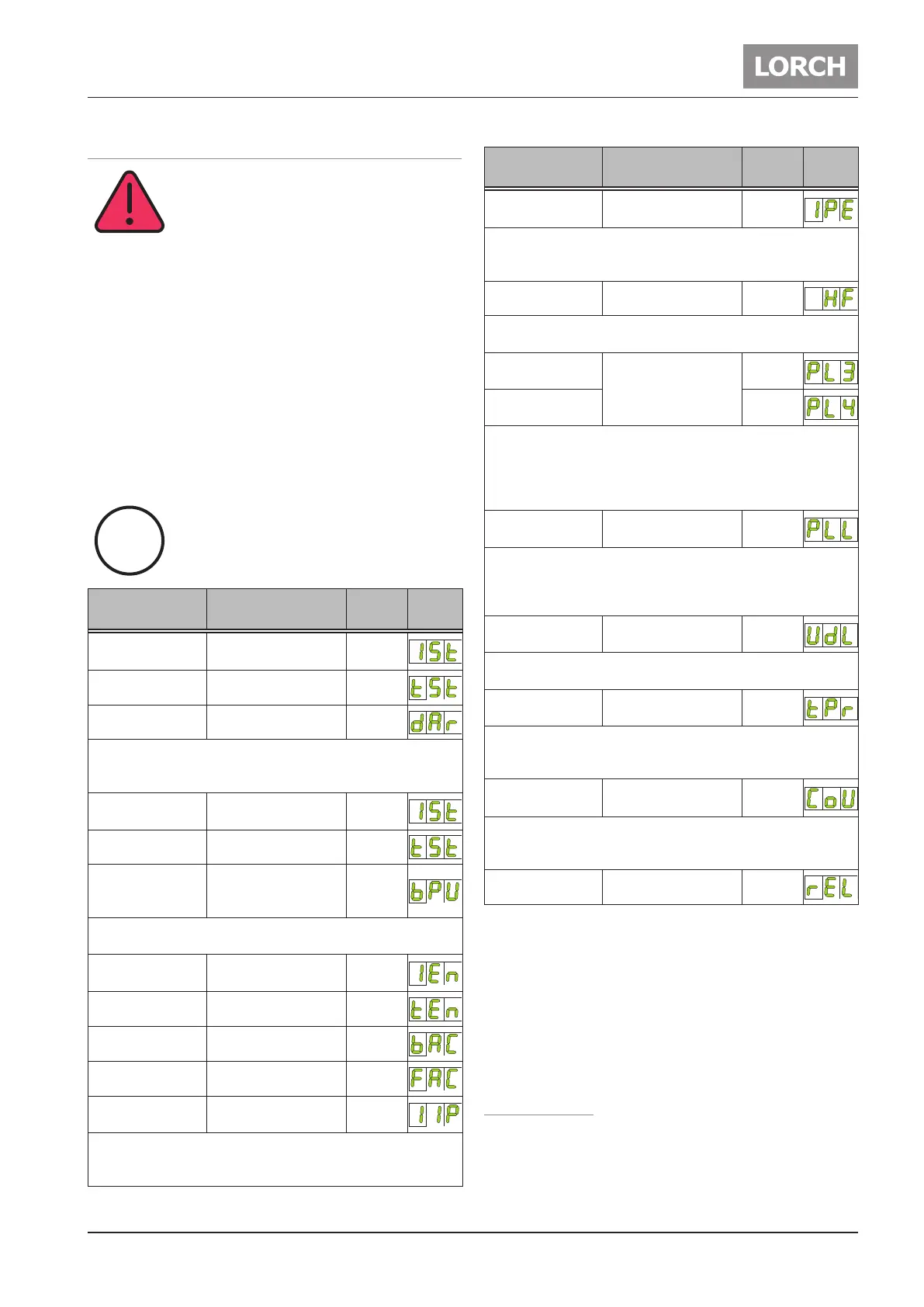

14.3 Secondary parameters

Danger due to electric shock!

If function HF-ignition is selected, a high ig-

nition voltage is present at the torch.

Never touch the welding electrode or parts

conducting welding current when the de-

vice is switched on.

The secondary parameters are set separately:

Press the welding process 30 and mode 47 buttons briey

simultaneously.

9 The 7-segment display 38 alternately displays the code of

the secondary parameter and its value.

Press the main parameter button 48 until the desired pa-

rameter appears.

Use knob 41 to set the desired value.

Briey press the welding process 30 or mode 47 button to

end this mode.

9 The changed values are accepted.

For more eective adjustment, all welding

parameters can be changed even during the

welding process.

Parameter Range

Factory

setting

LED/

Code

Hotstart IS

1

5 - 200 %

of main current

125

Hotstart time tS

1

0 - 20 sec. 1,0

Arc dynamic

1

0 - 200 % 100

The welding current increases automatically as the welding volt-

age is reduced. The arc dynamic indicates the ratio between the

main current and the automatic increase.

Start current

2

5 - 200 %

of main current

50

Start current time

2

0 - 20 sec. 0,1

Pulse duty factor

2

(only for pulse

mode)

1 - 99 % 50

Indicates the percentage ratio between main current I1 and auxil-

iary current I2. If the value set is 30, the ratio is 30 % I1 to 70 % I2.

Final current

2

5 - 200 %

of main current

25

Final current time

2

0 - 20 sec. 0,2

AC balance

3

10 - 90 % 35

AC frequency

3

30 - 200 Hz 60

Positive current

correction

2, 3, 4

10 - 200 % 100

Ignition using the Positive current is used for optimum dome for-

mation in TIG AC welding. This positive current is preset in the unit

and can be increased or reduced by the quoted percentage.

Parameter Range

Factory

setting

LED/

Code

I

gnition peak

correction

2, 4

10 - 200 % 100

The ignition peak current is set after ignition to provide stabilisa-

tion of the arc. This ignition peak current is preset in the unit and

can be increased or reduced by the quoted percentage.

HF On/O

2

On - O On

HF ignition is a contactless ignition brought about by high-voltage

impulses.

Powermaster LED 3

all Powermaster param-

eters

I2

Powermaster LED 4 -

All Powermaster torches of the i-LTG/i-LTW – series have two free

programmable parameter spaces. Depending on the type of weld-

ing machine and operating mode, dierent parameters can be

selected (please also see „14.4 Powermaster parameters“ on page

40).

Powermaster LED

lock

OFF, ON OFF

ON: mode button at the torch of the i-LTG/i-LTW serie is locked. By

pressing the mode button for 2 seconds, the button is unlocked

for 15 seconds. If the start/stop-button is pressed during these 15

seconds, the mode button is immediately locked.

up / down lock OFF, ON OFF

ON: during the welding (I>0), the up / down buttons at the torches

of the i-LTG/i-LTW-series are locked.

Torch protect

2

OFF, ON OFF

ON: if a torch of the i-LTG/i-LTW –series is used, only a welding

current up to the max. torch strain limit can be adjusted at the

welding machine.

cooling permanent

ON

2

Aut = Auto, On Aut

AUT: water cooling unit (WUK) switches on / o automatically.

ON: after the rst current (I>0) the WUK is switched on and stays

on permanently.

Version info - -

Tab. 3: Secondary parameters

1)

Only for electrode welding process

2)

Only for TIG welding process

3)

Only for TIG welding process

4)

Factory setting for electrodes -Ø 2.4 mm

for electrodes-Ø < 2.4 mm: Reduce parameter value

for electrodes-Ø > 2.4 mm: Increase parameter value

i

Loading...

Loading...