Starting up

- 40 - 01.21909.2669.9-02

14.4 Powermaster parameters

All Powermaster torches of the i-LTG/i-LTW – serie have two

free programmable parameter spaces (PL3 and PL4).

Select sub parameter PL3 or PL4.

9 The 7-segment display 38 shows alternating code PL3 or

PL4 and the code of the selected Powermaster parameter.

Select the required Powermaster parameter with the turn-

ing knob 41.

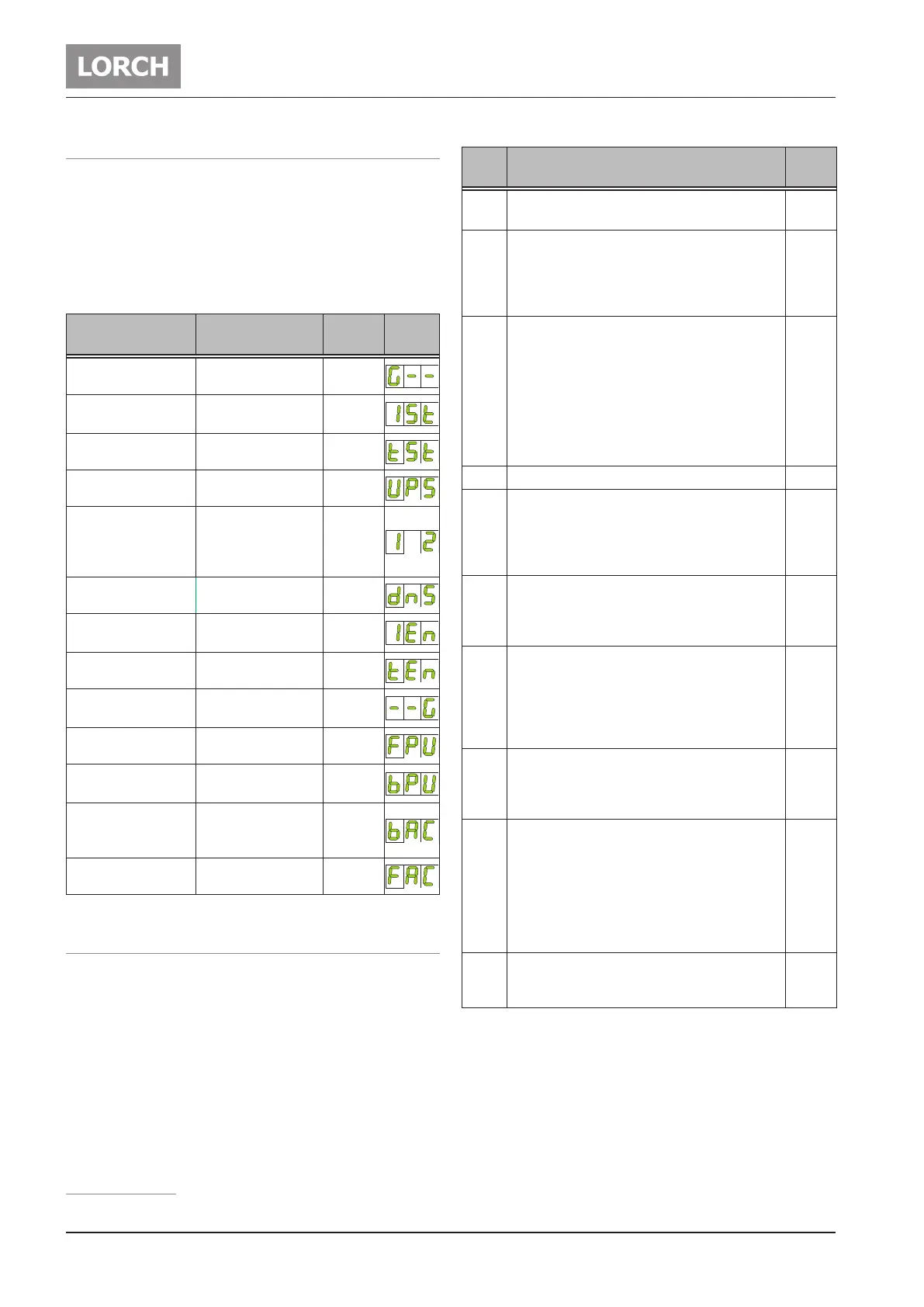

Parameter Range

Factory

setting

Code

Gas pre-ow time 0,1 - 10 sec 0,1

Start current IS

5 - 200 %

of main current

50

Start current time 0 - 20 sec. 0,1

Upslope 0 - 99 % 5

Second current I2

1 - 200 %

of main current

representation in

Amp.

50

Downslope 0 - 99 % 20

Final current IE

5 - 200 %

of main current

25

Final current time tE 0 - 20 sec. 0,2

Gas post-ow time

correction

20 - 500 % 100

Pulse frequency 0,2 - 2000 Hz 5

Pulse duty factor

1 - 99 %

Main current I1

50

AC-balance

1

10 - 90 %

positive welding

current

35

AC-frequency

1

30 - 200 Hz 60

Tab. 4: Powermaster parameters

1)

14.5 User-specic menu

Switch o the equipment at the main switch 9.

Press the selection button on the left 30 and keep it de-

pressed.

Switch on the equipment at the main switch 9

9 The user-specic menu is activated. The menu item and its

set value are shown alternating in the 7-segment display

38

Press the selection button 30 or 47 to switch among the

menu items.

Turn the control dial 41 to change the set value.

1)

Only for AC/DC

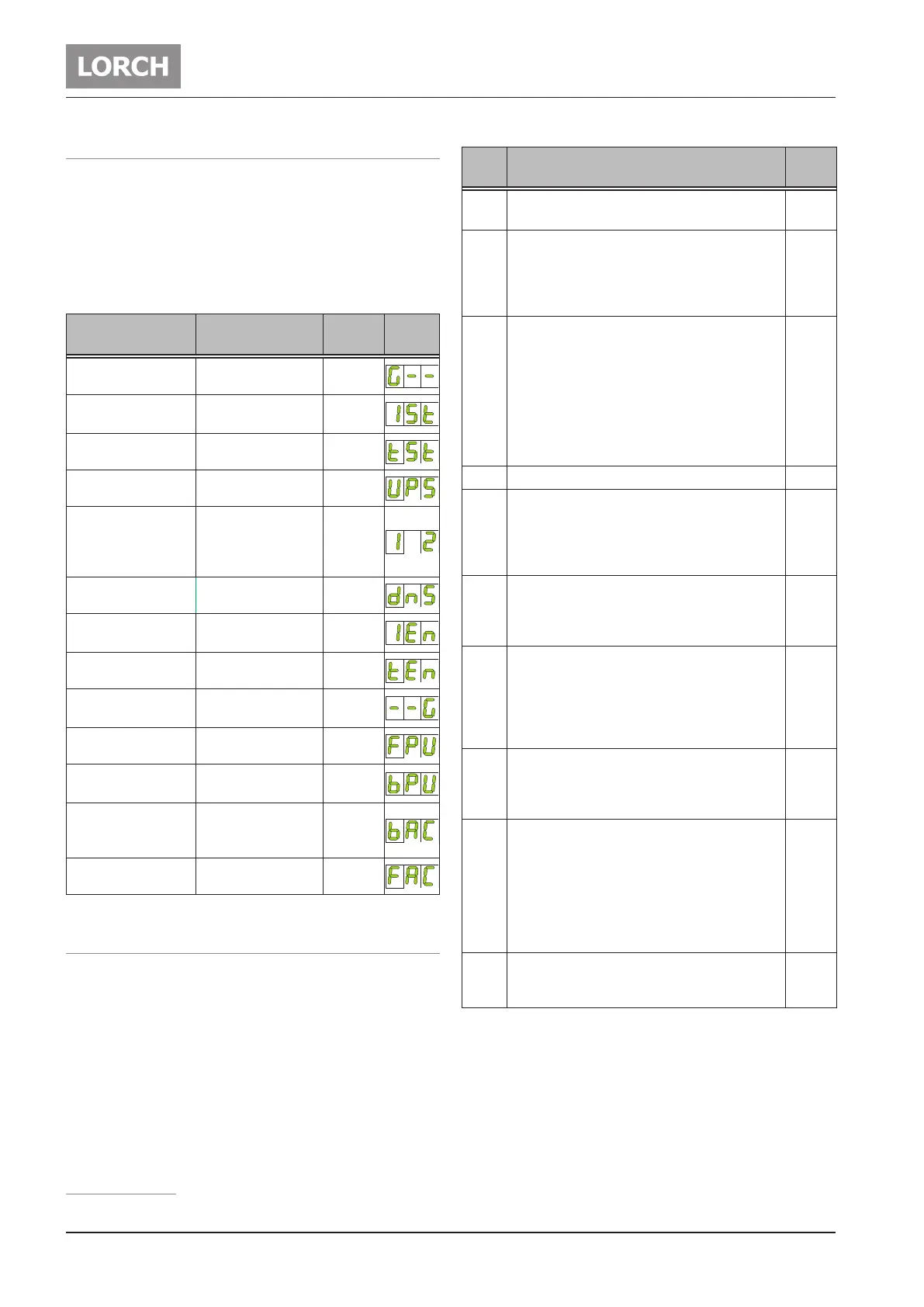

Menu

no.

Menu item

Setting

values

C00 Display and adjustment of the torch-ID. See „Ad-

justment of the torch-ID“ on page 41.

9...45

C01 Welding current limit for up/down torch. When

the welding current limit is switched to “On”, the

welding current on the up/down torch cannot

be set higher than pre-selected on the control

terminal.

On-O

C02 Deactivation of the error message E05-00 (water

pump) and of the water cooling unit by Lorch-

Net.

If the deactivation is switched “on”, the error mes-

sage E05-00 (water pump) is no longer displayed.

Also the water cooling unit is not switched on by

LorchNet.

Practical, e.g. for the use of an automatic torch

without plug or a cooling unit without LorchNet.

On-O

C03 Activation of the orbital welding mode. On-O

C04 ON: at short circuit the welding current don’t

increase the adjusted welding current shown in

the display (set value).

O: at short circuit the welding current is in-

creased on minimum 60 A.

On-O

C05 ON: by quick pressing of torch button 1 (start /

stop) the 2nd torch button is simulated.

(Second current on / o). Useful e.g. for torches

with one button only.

On-O

C06 ON: the current decrease (downslope) will be - as

adjusted – conducted, also if the torch button is

released (4th tact).

O: at earlier release of the torch button (4th

tact) the current decrease (downslope) is inter-

rupted.

On-O

C07 On: PE conductor monitoring activated

O: PE conductor monitoring deactivated

the PE conductor monitoring is an optional avail-

able feature

On-O

C08 O: Using a foot remote control, the minimum

current (independent from the adjusted welding

current) in the TIG mode / AC at

electrode-Ø 1,0...2,0 mm = 10 Amps

electrode -Ø 2,4 mm = 15 Amps

electrode -Ø 3,2 mm = 20 Amps

On: the increased minimum current in the TIG-

mode / AC is deactivated

On-O

C10 Welding current limit

0 = O

I1

Min

...I1

Max

= On

0,

I1

Min

...

I1

Max

Tab. 5: User-specic menu

Switch the equipment o at the main switch 9 to transfer

the settings from the user-specic menu.

Loading...

Loading...