Top climate system

with LUBING Touch Controller

Copyright © Lubing System - All rights reserved

19

IMPORTANT INFORMATION

Make sure that no impurities or dirt get into the pipe system. This will ensure that the nozzles will work

properly later on.

4.5.1 Positioning and orientation of nozzle lines

The following details are recommendations which have often proven themselves in practice. Depending on the

ambient conditions (air ow, barn equipment, etc.), the optimum installation of the nozzle lines may differ from the

recommendations.

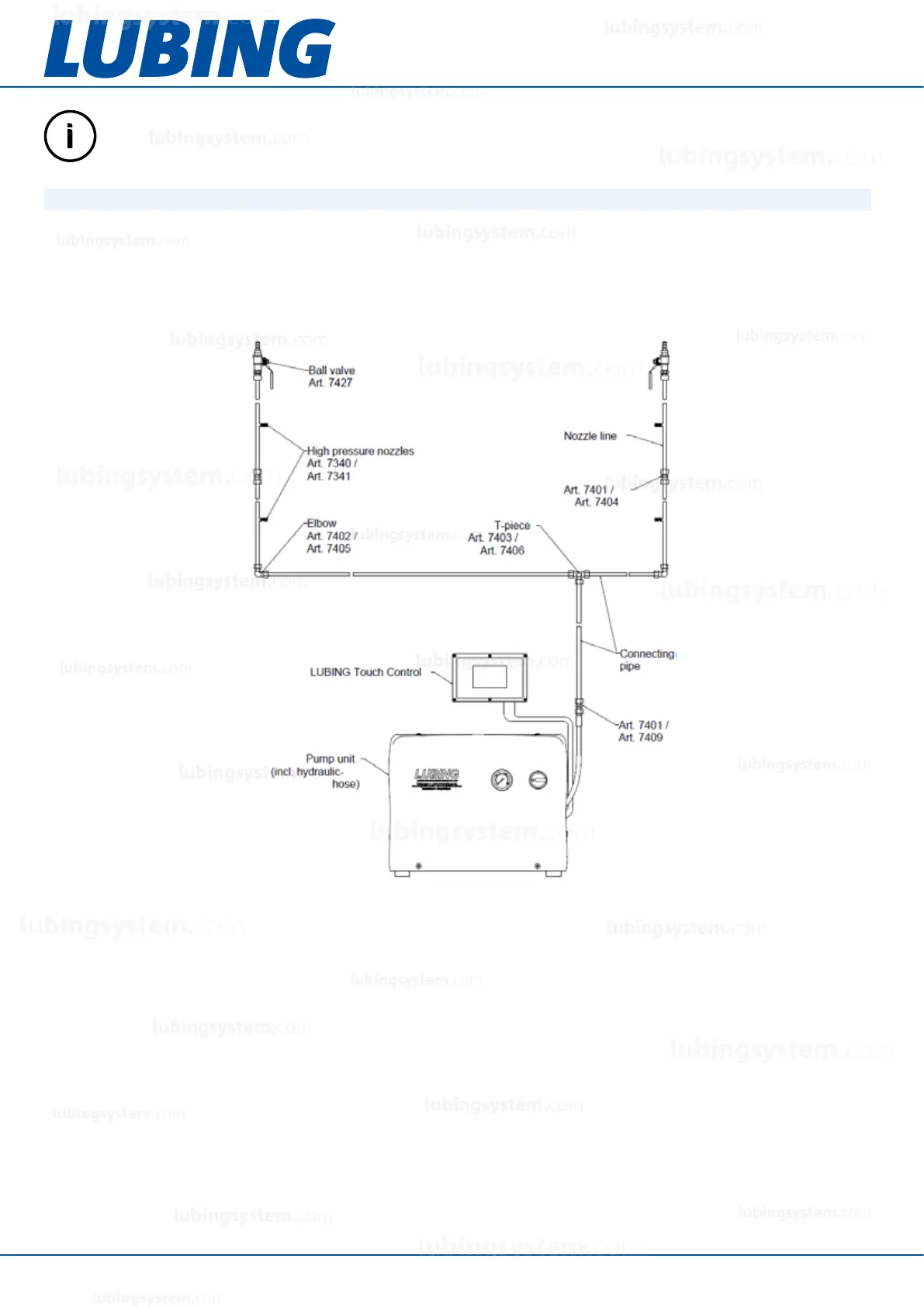

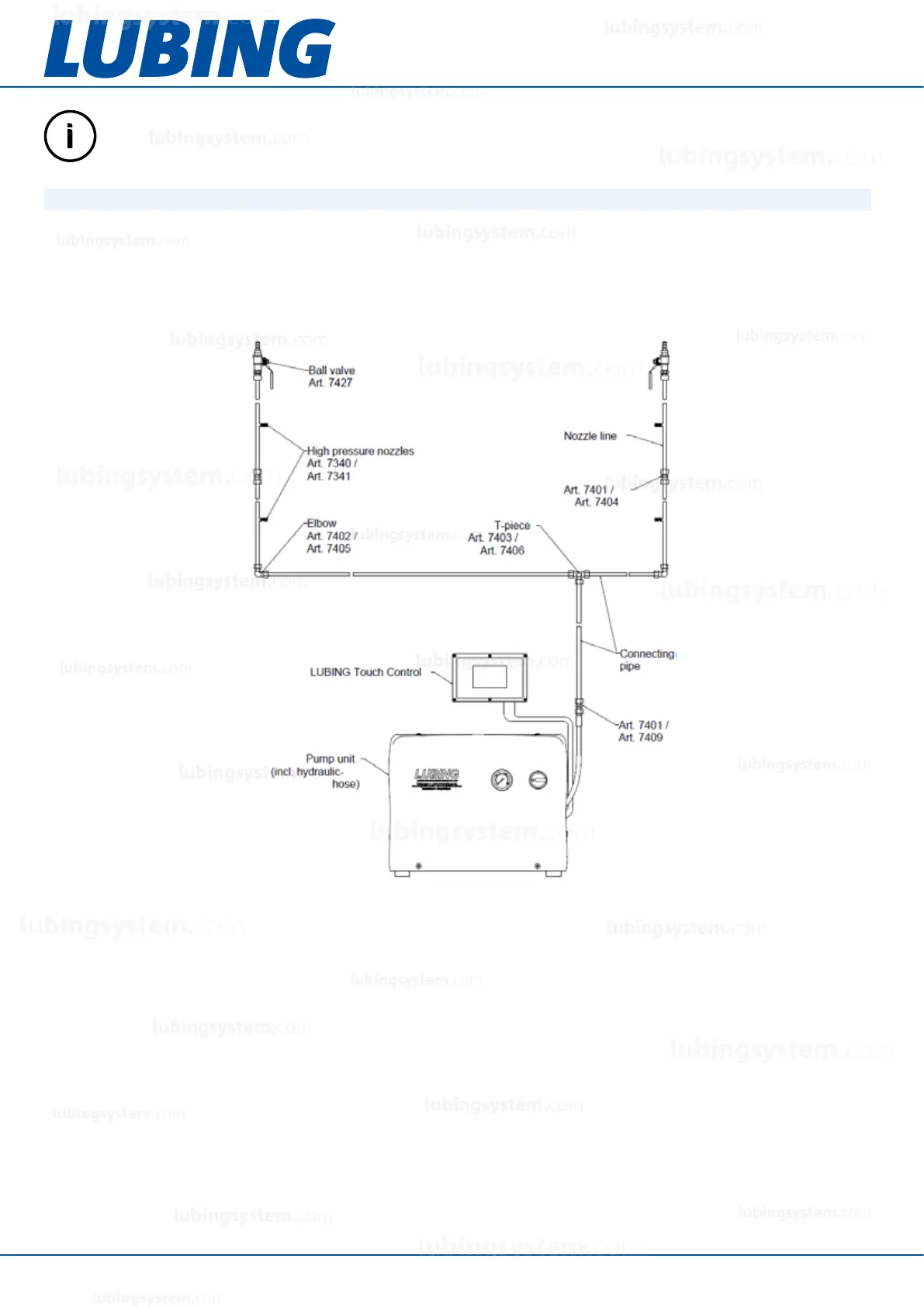

The following illustration shows in principle a possible arrangement of the components in a system. In addition

there are components in the supply line to the pump unit (lter unit etc.). The ball valves at the ends of the lines can

be opened for ushing and venting.

Depending on the size of the barn and the ventilation system, the layout of the nozzle lines is determined. Generally

applies:

– the nozzles should not spray against the air ow.

– the minimum distance to the ceiling of at least 0.5m should be maintained.

– there should be a free space of at least 3m in the spraying direction of the nozzle. In case of obstacles in this

free space, these adapters can be closed with plugs (Art. 7326).

– the line lengths should be kept as short as possible to minimize pressure losses (espe cially with high ow

rates!).

The following sketches show examples of possible layouts:

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

c

lubingsystem.com

lubingsystem.com

Loading...

Loading...