Top climate system

with LUBING Touch Controller

Copyright © Lubing System - All rights reserved

40

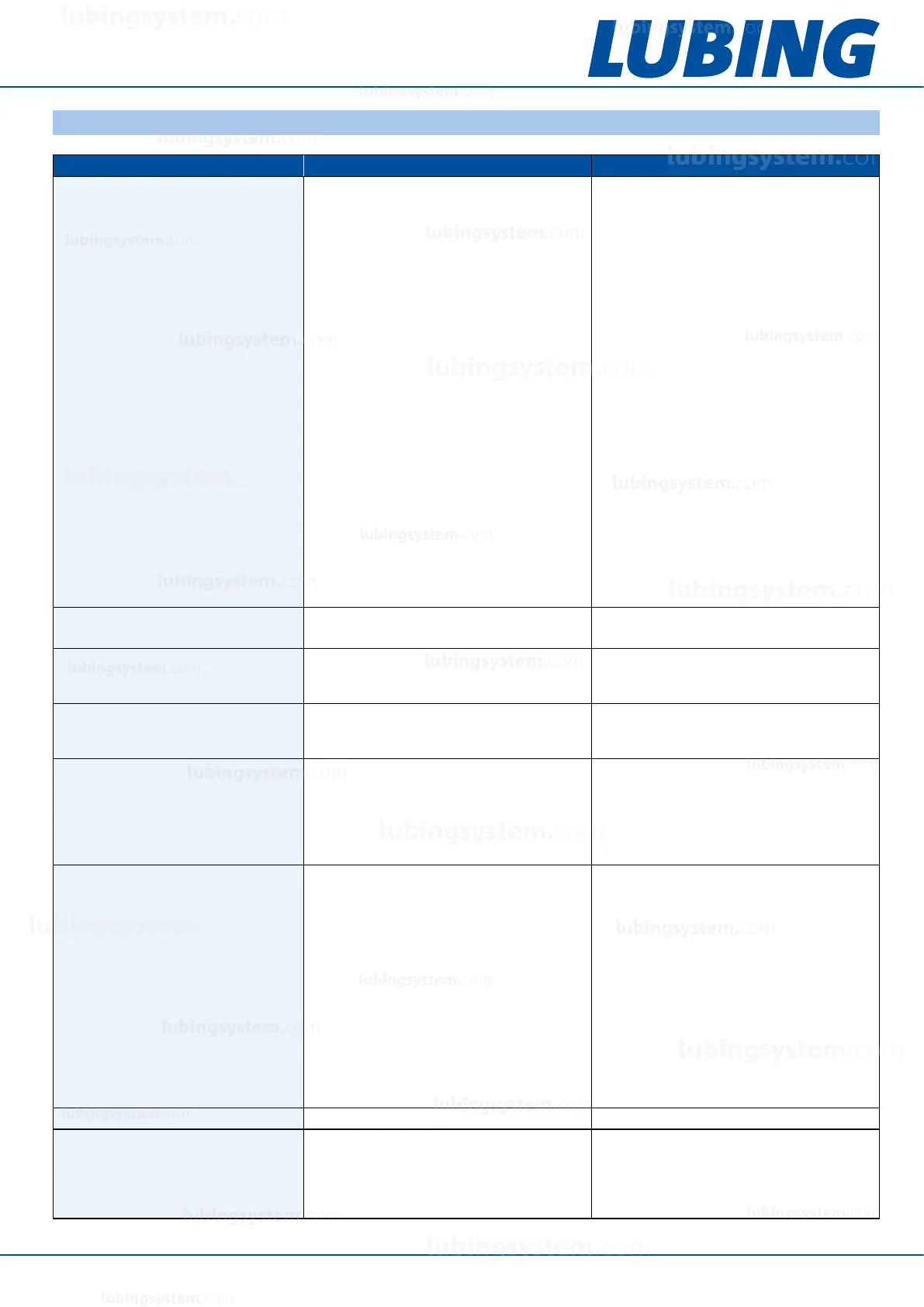

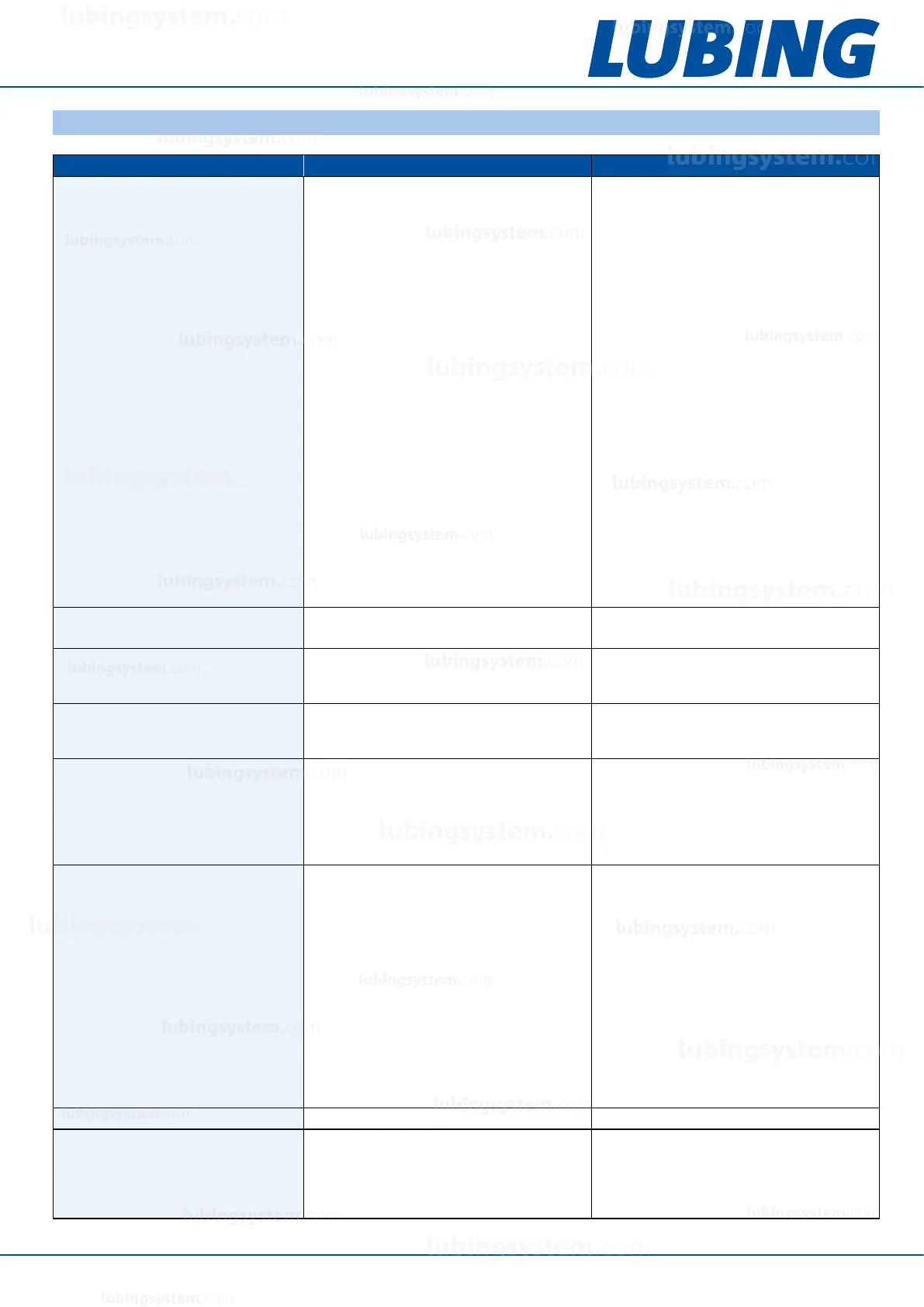

7.2 Faults pump system

FAULT CAUSE REMEDY

The pump is running, but does

not reach sufcient pressure.

• Main valve does not open, e.g.

due to faulty connections or

defective solenoid coil.

• Main valve does not open

completely, because e.g. the

membrane is damaged (torn).

• Inlet pressure not sufcient during

operation

• Filters blocked

• The pump sucks in air

• Pump valves are leaking

• Pressure regulator is worn out or

incorrectly adjusted

• Leaking pressure lines

• Leaking seals

• Pump speed too low

• Pump ow rate too low for the

connected nozzle system

• Pressure relief valve not closed

• Pressure gauge defective

• Repair connections or replace

solenoid

• Repair main valve (replace dia-

phragm); if membrane is defective

frequently, check pump valves and

pressure regulator and replace if

necessary.

• Increase inlet pressure, check

dimensioning of supply line

• Replace lter cartridges

• Check the supply line and ensure

that it is absolutely airtight

• Replace valves

• Replace pressure regulator or

correct setting

• Check pressure lines

• Replace seals

• Check drive

• Check the dimensioning of the

nozzle system and the selection of

the pump and correct if necessary

• Repair/replace pressure relief

valve

• Replace pressure gauge

The pump runs, but reaches the

rated pressure very slowly.

• Air in the high-pressure lines • Vent high-pressure lines

Nozzles drip on for a long time. • Pressure relief defective/not

installed

• Air in the high-pressure lines

• Repair/Retrot pressure relief

• Vent high-pressure lines

Shocks in the high-pressure

lines

• Air in the high-pressure lines

• Insufcient mounting

• Pressure uctuations

• Vent high-pressure lines

• Improve xation

• See following notes

Irregular pressure uctuations • Worn pump valves

• Foreign objects in the pump valves

• The pump sucks in air

• Leaking seals

• Pressure regulator does not

function properly

• Replace pump valves

• Clean valves

• Check supply line (air bubbles?)

• Replace seals

• Replace pressure regulator

Increase in noise level • The pump sucks in air

• Cavitation due to insufcient water

supply (low pressure, suction line

too small or blocked, main valve

defective, lter blocked, high

water temperature)

• Inlet pressure not sufcient during

operation

• Too high temperatures of the

pumped liquids

• Valve spring broken or softened

• Foreign objects in the pump valves

• Bearings worn out

• Check the supply line and ensure

that it is absolutely airtight

• Check the water supply

• Increase inlet pressure, check

dimensioning of supply line

• Reduce the temperature of the

pumped liquid.

• Replace pump valves

• Clean valves

• Replace pump or repair bearings

Oil leakage at the drive shaft • Shaft seal defective • Replace seal

Water in the oil (white emulsion) • Seals damaged or worn out

• High humidity (condensation

water)

• Piston damaged or worn (hairline

crack?)

• Replace seals

• Change oil and reduce oil change

interval by half.

• Replace piston

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

c

lubingsystem.com

lubingsystem.com

Loading...

Loading...