Top climate system

with LUBING Touch Controller

Copyright © Lubing System - All rights reserved

41

FAULT CAUSE REMEDY

Water leakage between pump

casing and pump head

• Worn gasket kit

• Worn or damaged piston

• Worn seal between piston and

piston screw

• Replace gasket kit

• Replace piston

• Replace seal

Overheating of the pump • Flow rate below minimum ow

rate

• Excessive air and/or water

temperature

• Poor ventilation

• Oil level in pump housing does not

meet specications

• Excessive heat input through the

drive/motor

• Increase ow rate (increase

number of nozzles)

• Reduce temperatures

• Ensure adequate ventilation

• Correct oil level

• Check and repair/replace the

drive/motor

FAULT CAUSE REMEDY

System can only build up

sufcient pressure when only

few compartments are in

operation

• Main valve does not open

completely, because e.g. the

membrane is damaged (torn)

• Pressure sensor defective

(continuously outputs too high

voltage above 7,5 V)

• Repair/replace main valve (e.g.

replace membrane)

• Replace pressure sensor

Motor runs at high speed even

with a small number of nozzles

• Pressure regulator is worn out

or incorrectly adjusted (pressure

always below rated pressure of

70 bar)

• Pressure sensor defective

(permanently outputs too low

voltage below 7,5 V)

• Replace pressure regulator or

correct setting

• Replace pressure sensor

System does not start any more • Frequency converter on fault

(diagnostic LED red)

• Frequency converter defective

• Incorrect/no software on the

frequency converter - diagnostic

LED ashes green (4Hz) - only the

fan is running

• Restart the system (main switch)

and, if necessary, rectify the cause

of the overload.

• Replace frequency converter;

when ordering, specify for which

pump it is required (software will

be installed)

• Re-install software (e.g. using

another EEPROM with correct

software)

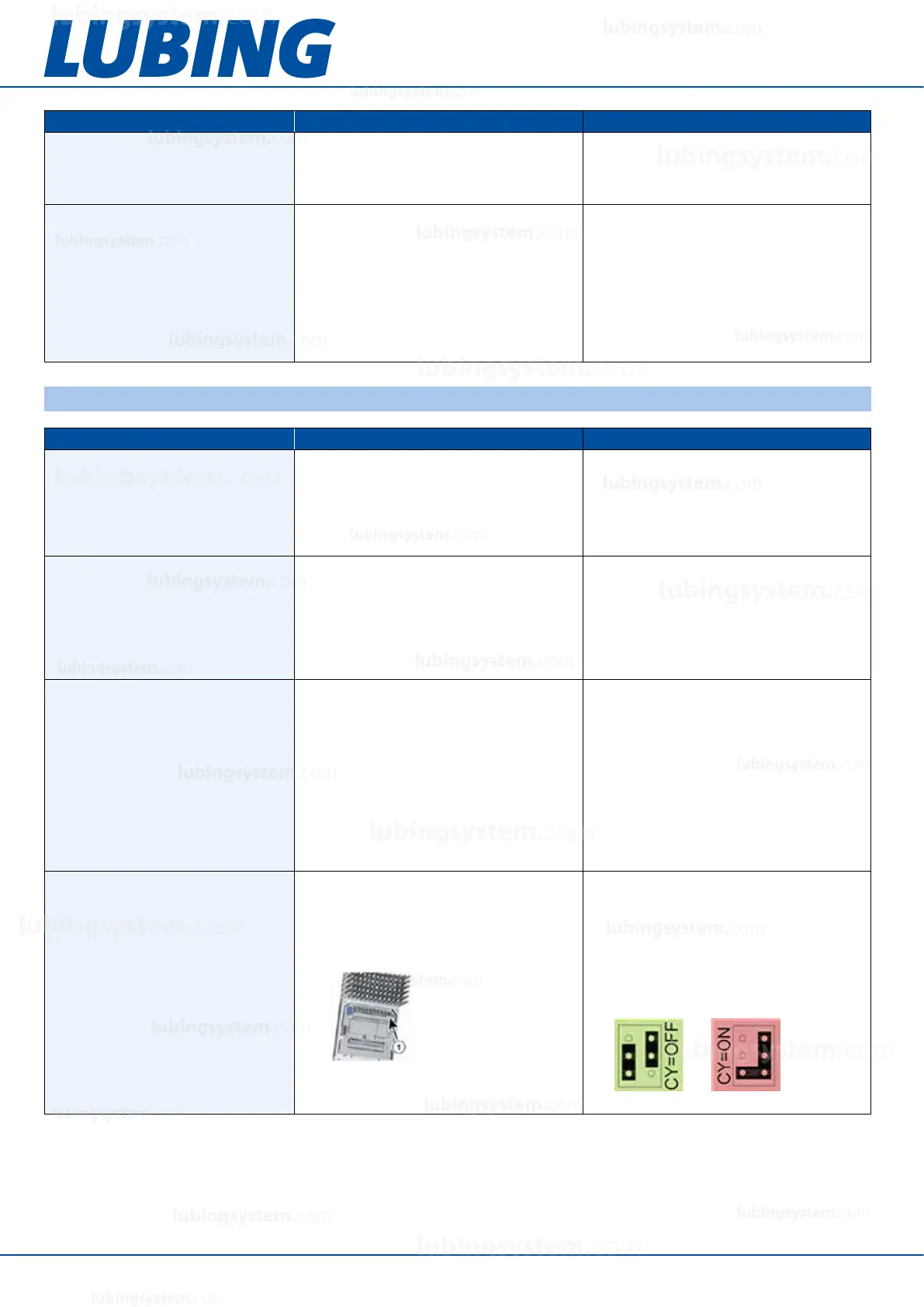

GFCI (ground fault circuit

interrupter) triggers

• Wrong FI installed

• Leakage currents > 40 mA

with active mains lter (jumper

in frequency inventer is set to

CY=ON)

• Install universal current sensitive

FI type B with 300 mA leakage

current

• Reduce leakage currents to 10-

20 mA by changing the jumpers

to CY=OFF - this measure will

result in a dete-rioration of radio

interference suppression!

• Eliminate error

7.3 Faults with Vario-pumps

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

lubingsystem.com

c

lubingsystem.com

lubingsystem.com

Loading...

Loading...