Appendix – EMC Compliance

128

Appendix

EMC Compliance

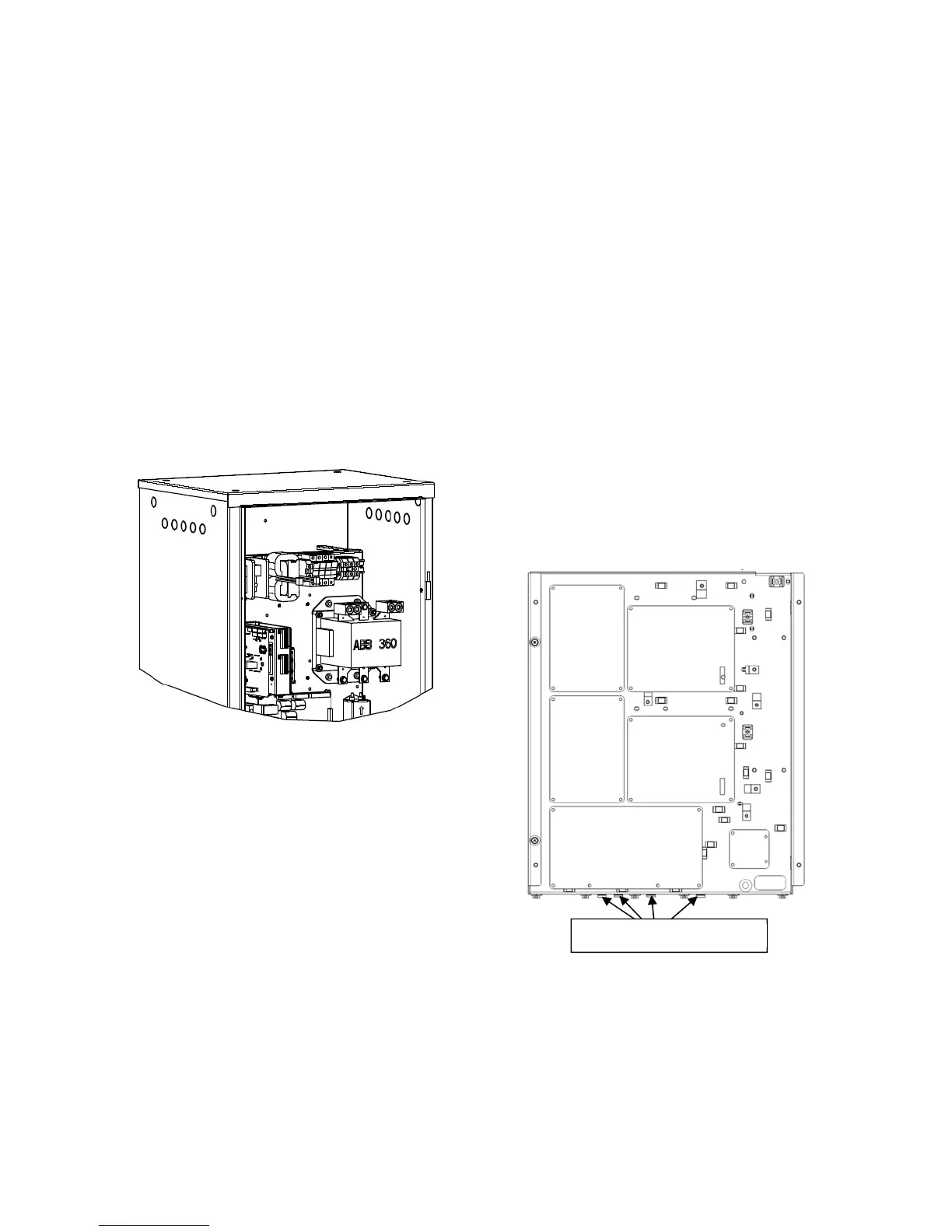

The Quattro DC drive requires EMC

Compliance (EN12015 and EN12016) to

function at the highest performance level

possible. The following pages will provide the

user with an installation guideline for field

personnel regarding proper metallic bonding

for EMC compliance. All necessary metallic

bonding within the Quattro cabinet will be

performed at the factory.

In order to be compliant with conducted and

radiated emissions standards, it is critical that

the motor leads are coupled correctly to the

chassis of the Quattro product. Ensuring

proper connections through the conduit plate

does this. The conduit plate is located on the

upper right hand corner of the cabinet.

Figure 21: Conduit Access

Proper bonding of motor wiring can be

achieved by using one of the following two

methods:

Method 1:

1. Use rigid conduit combined with

appropriate conduit couplings for an

acceptable metallic bond to the conduit

plate. Note: The conduit can only contain

the armature and field lines. No

communication or encoder feedback wires

can be run through this conduit.

2. Verify proper conduit connections to the

galvanized side panels located on the

Quattro drive.

Method 2:

1. Use braided, shielded leads for the DC

armature and for the motor field

connections. Note: When shielded multi-

conductor wire is used, it is very important

to use termination couplings that are

designed for this type of installation.

These couplings are designed to make a

bond to the braid, which will complete the

metallic connection to the chassis.

2. Verify proper connection of the braided

shield to the galvanized side panels

located on the Quattro drive.

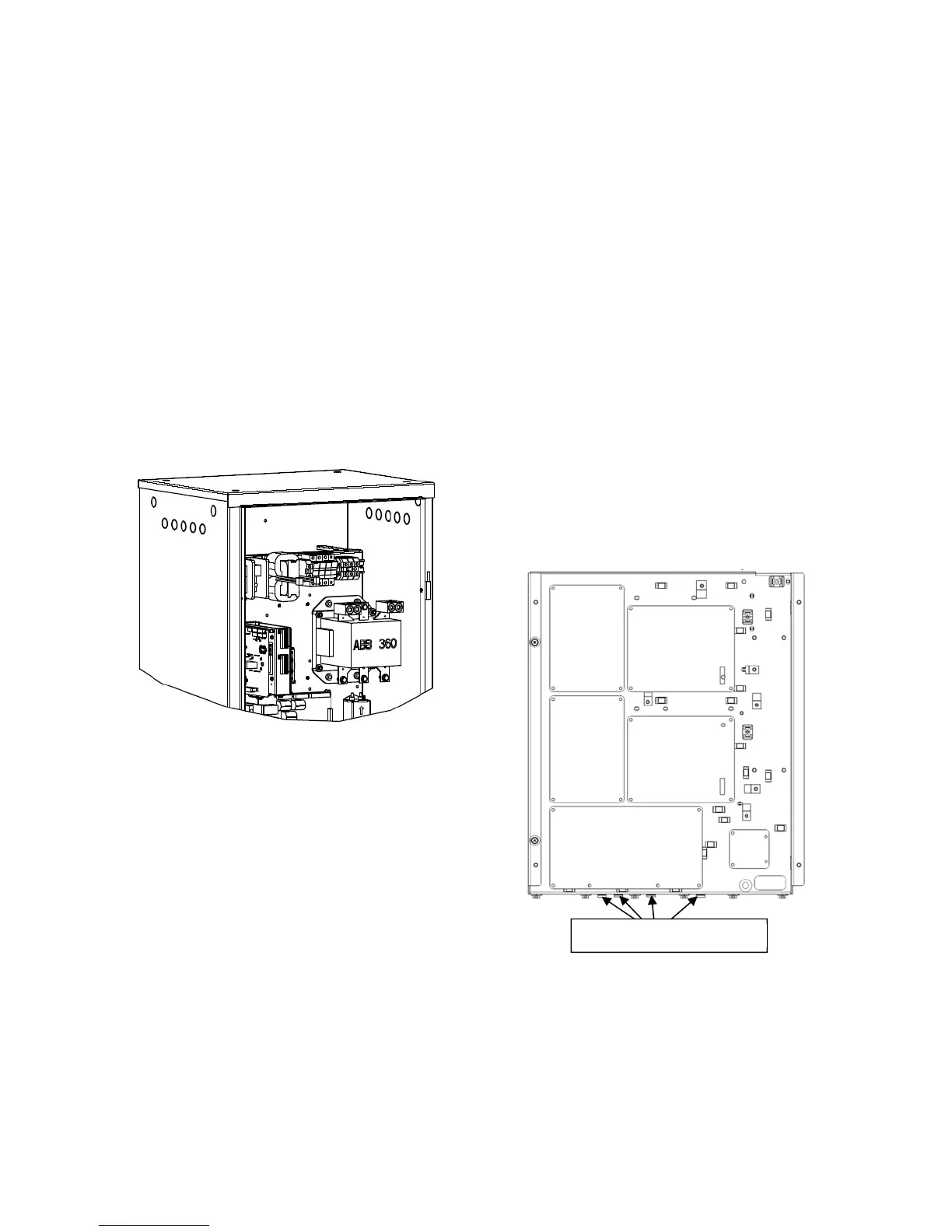

Proper bonding of encoder cables and

communication wiring may be seen in. All

shielded multi-conductor cables used for

communications or for the encoder feedback

must be the braided type.

There are several places along the edge of the

lower part on the card cage near the customer

I/O board to mount a braided clamp.

Figure 22: Encoder Cable Clamp

Encoder Cable

Loading...

Loading...