20

WORKING INSTALLATION

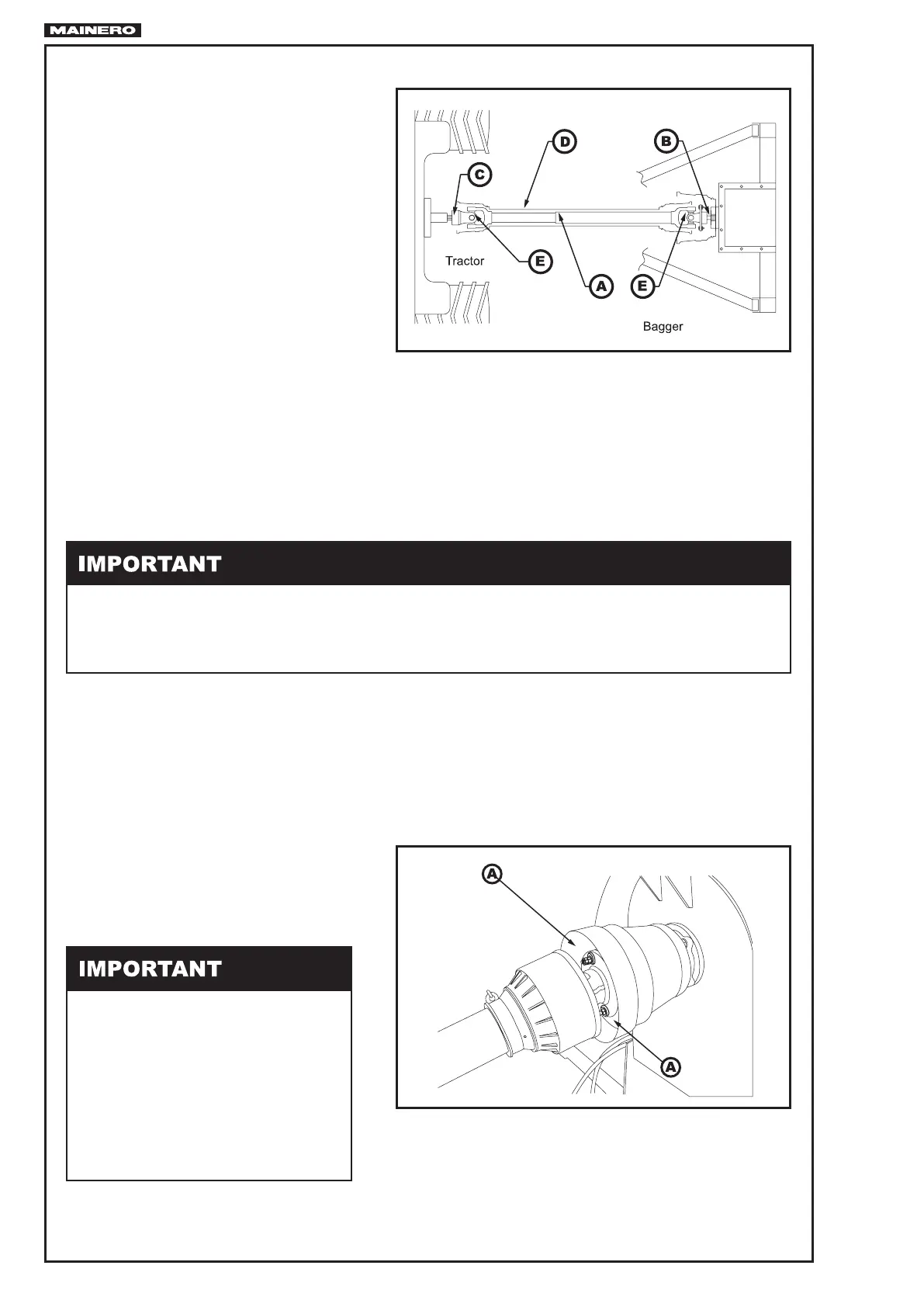

After executed length corrections, pro-

ceed to the denitive working installation:

1. Lubricate the telescopic section “A”

Fig 23.

2. Assamble metallic sections and pro-

tections.

3. Set the ends of the PTO shft at:

a) The imput shaft of the machine,

verifying proper installation of

the lock “B” Fig. 23.

b) The tractor, verifying the correct

coupling of the lock “C”.

4. Verify the protections “D” turn freely.

5. Then attach the safety chains to prevent spinning during work, with enough clearence perform normal

movements.

6. Lubricate the grease nipples “E” Fig. 23 according to the plan indicated at the Lubrication Plan on this

manual.

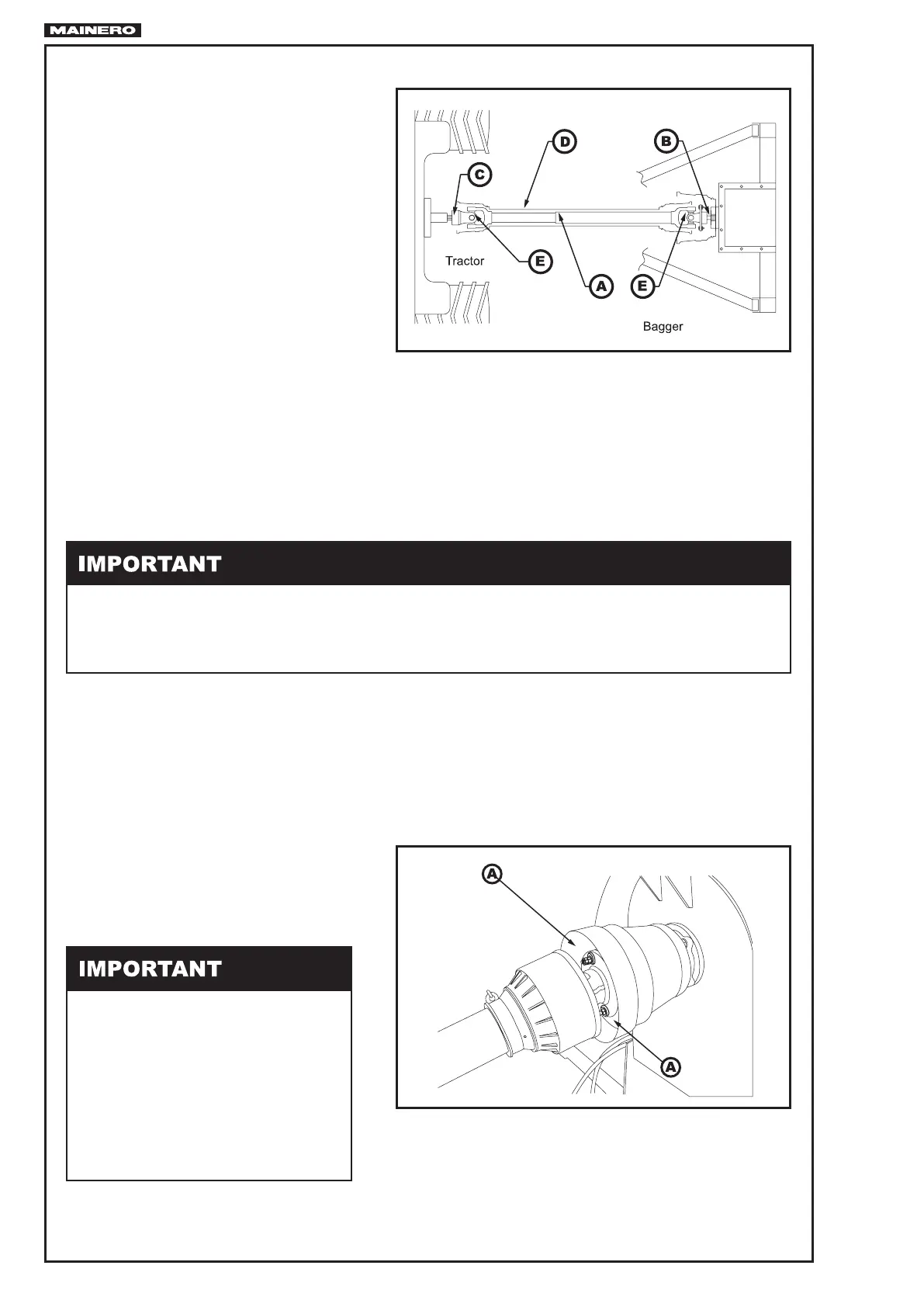

SHEAR BOLT

The PTO Shaft has installed one shear bolt

“A” Fig. 24, which act when any overload

at the auger exists.

The bolt used is:

For PTO Shaft B & P

Hexagon head bolt. Gº 8.8

RM 8 x 45 mm. . . . . . . . . 21705-346

- The PTO shaft demands to the operator “MAXIMUM” caution during work.

- Check at those tractors which posses protections at the zone were the PTO shaft is coupled, it does

not interfere normal function during work.

- Make sure when assembling the shaft that it “DO NOT” moves axially on the shaft.

FIG.23

FIG.24

Always use the bolt size and quality

stated, do not use a higher quality or

larger size because can affect the par-

ts to be powered.

If the shear bolt gets cut, identify the

cause for which this happened, and

solve the inconvenience before restart

the work.

Loading...

Loading...