41

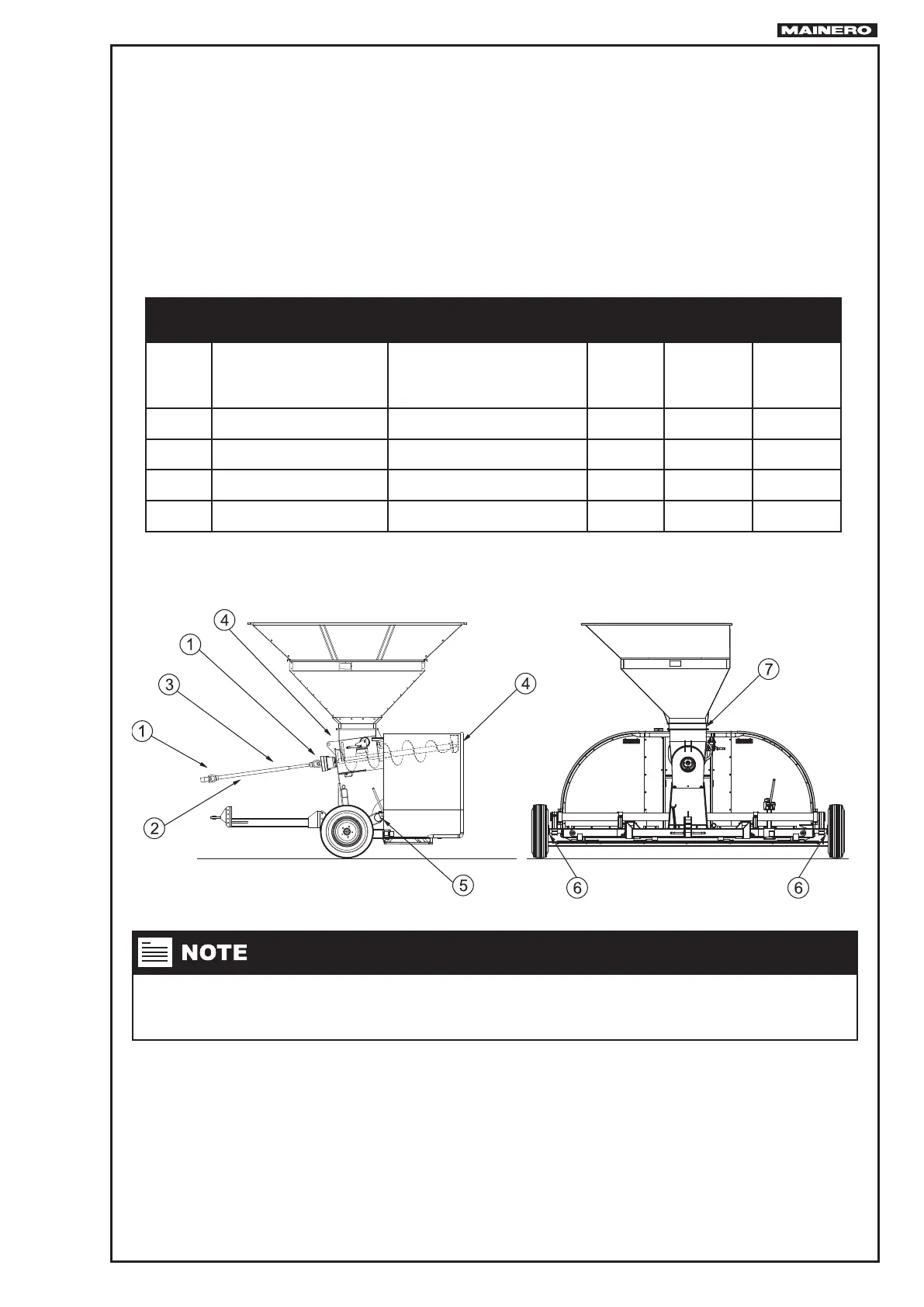

POS. SECTOR DETAIL

CANT.

NIPLES

LUBRIC..

PERIOD IN

HOURS

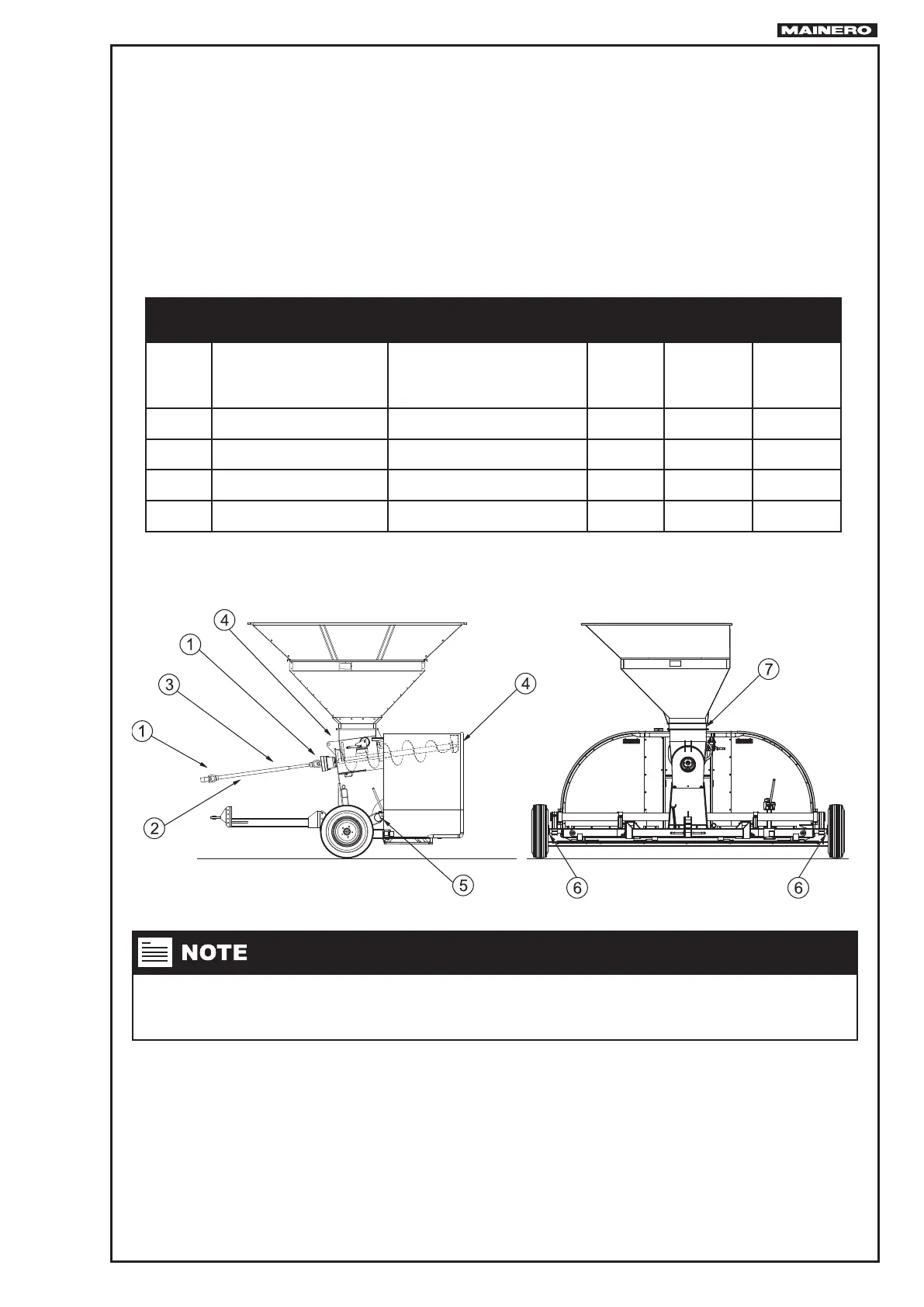

1

2

3

PTO SHAFT

Spider and fork

Telescopic sector

Protections

2

-

-

Grease

20

50

20

4 AUGER Bearing Box 2 Grease 50

5 AXLW WHEEL Benchs 3 Grease 100

6 TYRES Wheel Hub 4 Grease 100

7 HOPPER Turning ring 2 Grease 50

Grease: Multiple use. Grade NLGI-2 . Soap lithium. Dripping point 185 °C.

TABLE OF LUBRICATION

The rejected oil from the hydraulic circuit or from lubrication, must get an adequate tratment, in accord to

the actual legal dispositions, Federal, State, etc., for the treatment of Hazardous Residues and minimize

the enviroment impact. For more information, contact your oils lubricants dealer.

LUBRICATION

For the initial start up is convenient that the operator accomplish a check and a general lubrication as a way

to get familliarized with the location of the greasing points.

• Clean the grase nipples anad the grease pump every time you proceed to lubricate.

• Replace all damaged nipple and reinstall the missing.

• Not only lubricate.

Loading...

Loading...