27

5. Put the brake of the machine in the

work place or were it is foresee to start

the bag.

6. Start the PTO at 400 RPM approxima-

tely.

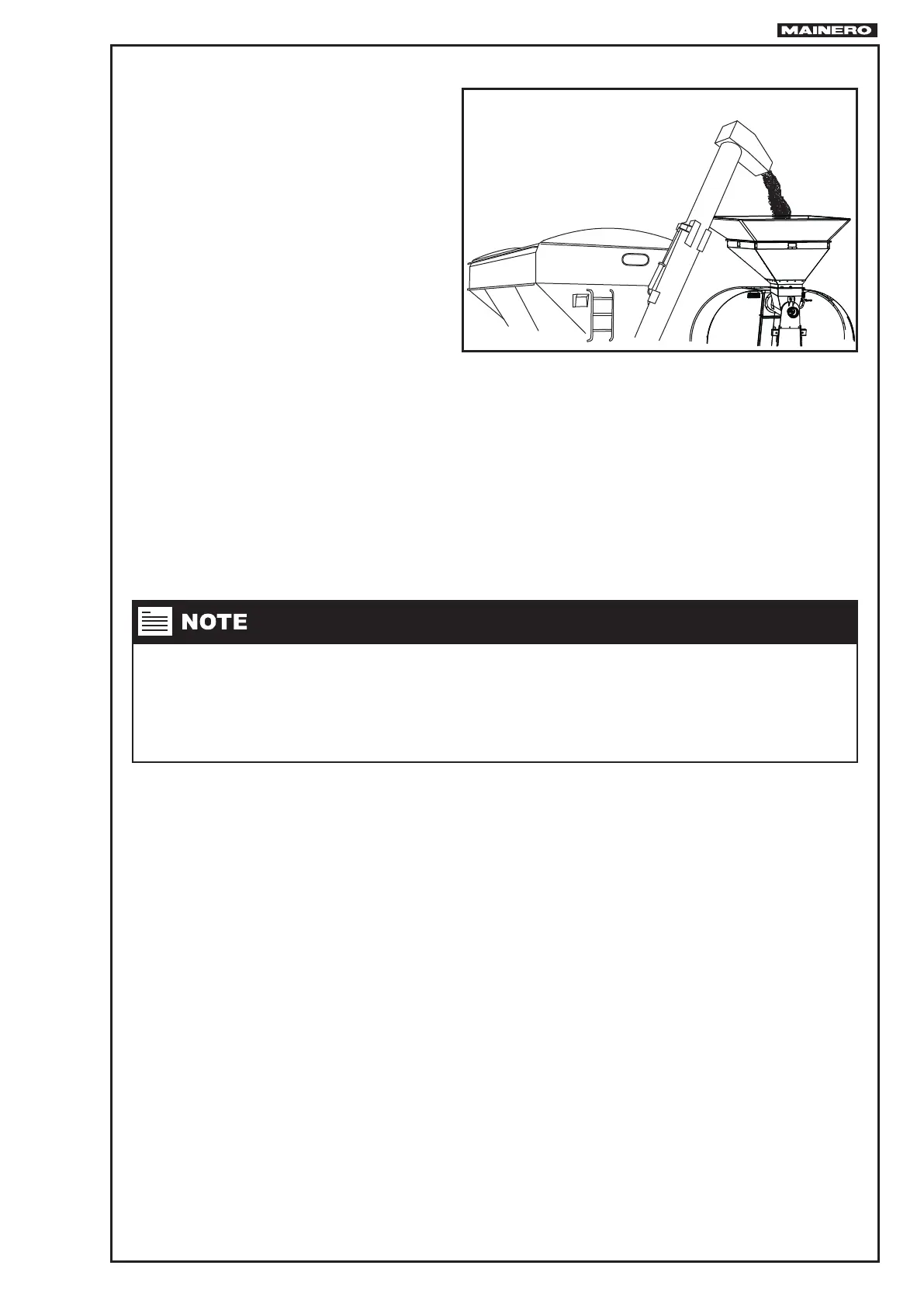

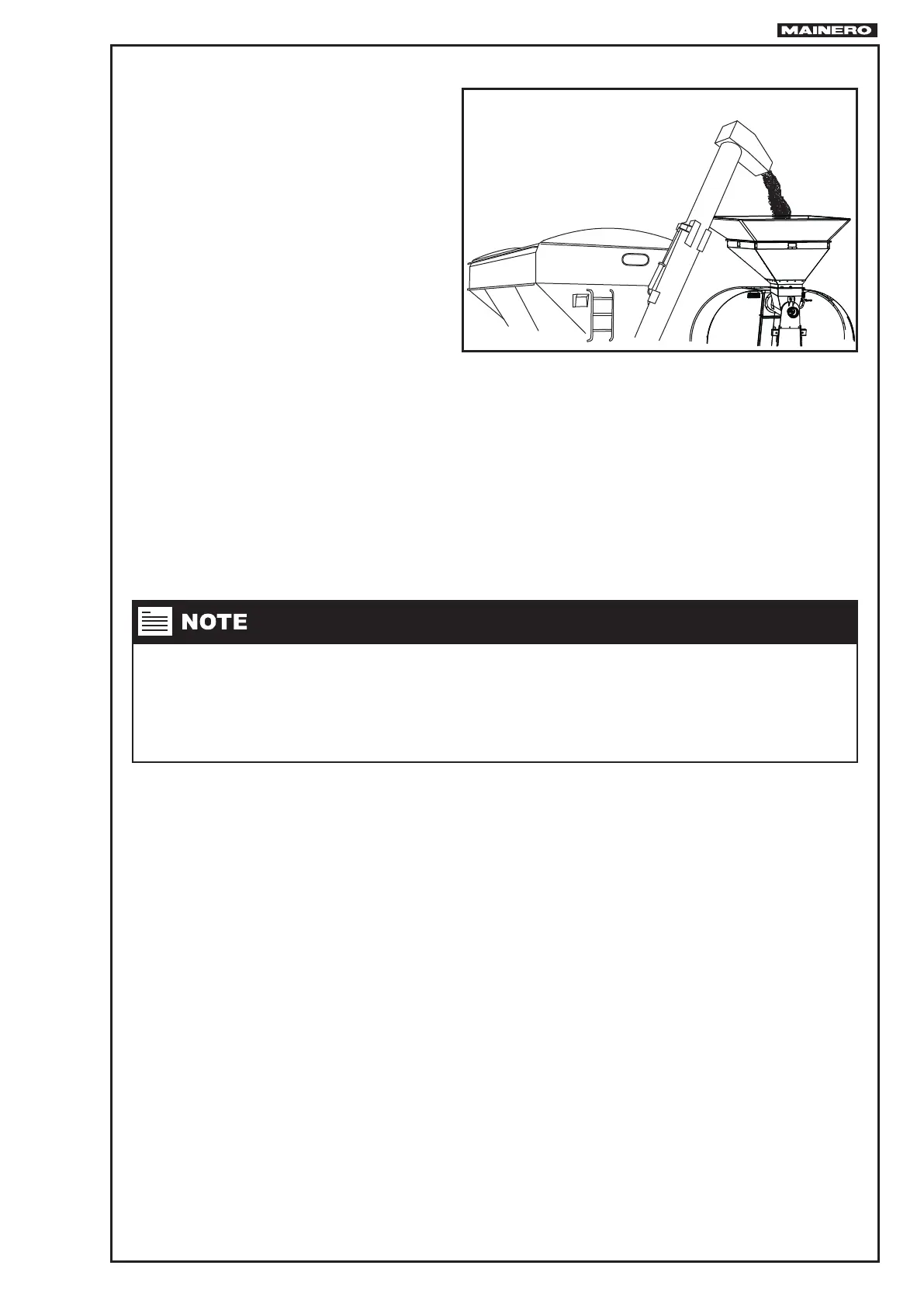

7. Start the uploading cereal from the self

unload wagon, in the grain hopper of

the bagger.

8. As the cereal begins to enter in the

bag (the machine do not moves), it is

essential to accomodate the bag at

both sides to avoid the folds formation.

It is convenient that clousure of the

bag is located under the bag. Fig. 42

9. When the machine starts to move on, is essential to increase the brake pressure (10 - 15 kg/cm² / 150

- 220 psi, each time maximum) and the machine height too (2 - 3 cm / 1 in, each time maximum) Until

reach an optimal work height of 25 - 28 cm (10 - 11 in) from the ground and a bag stretching between

the values indicated by the manufacturer.

10. Increase the tractor RPM if it´s needed more baggin capacity by the machine or it´s manifested any

overload at the tractor engine.

11. Drive properly the tractor to achieve a well aligned bag. Do not actuate the tractor brakes.

OBSERVATIONS:

A - If it is noticed that the bagger tire slices (loose, wet ground) it will be necesary to decrease the

brake pressure until stop sliding (don´t execute this decrease abruptly).

B - Every time it has to be modied the brake pressure up or down, do it in small values, if necessary

in severals steps (this change is manifested in the bag uniformity).

The height adjustments, until reach the work height must be done in a distance not longer than 2 m (6.5

ft), once reached this, close the hydraulic cylinder valve.

Do the brake adjustment according to the stretching of the bag (maximum admissible pressure by the

brake circuit is 200 kg/cm² - 3000 psi).

FIG.42

Loading...

Loading...