P 27/ 45

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -9. Support arm (cont.)

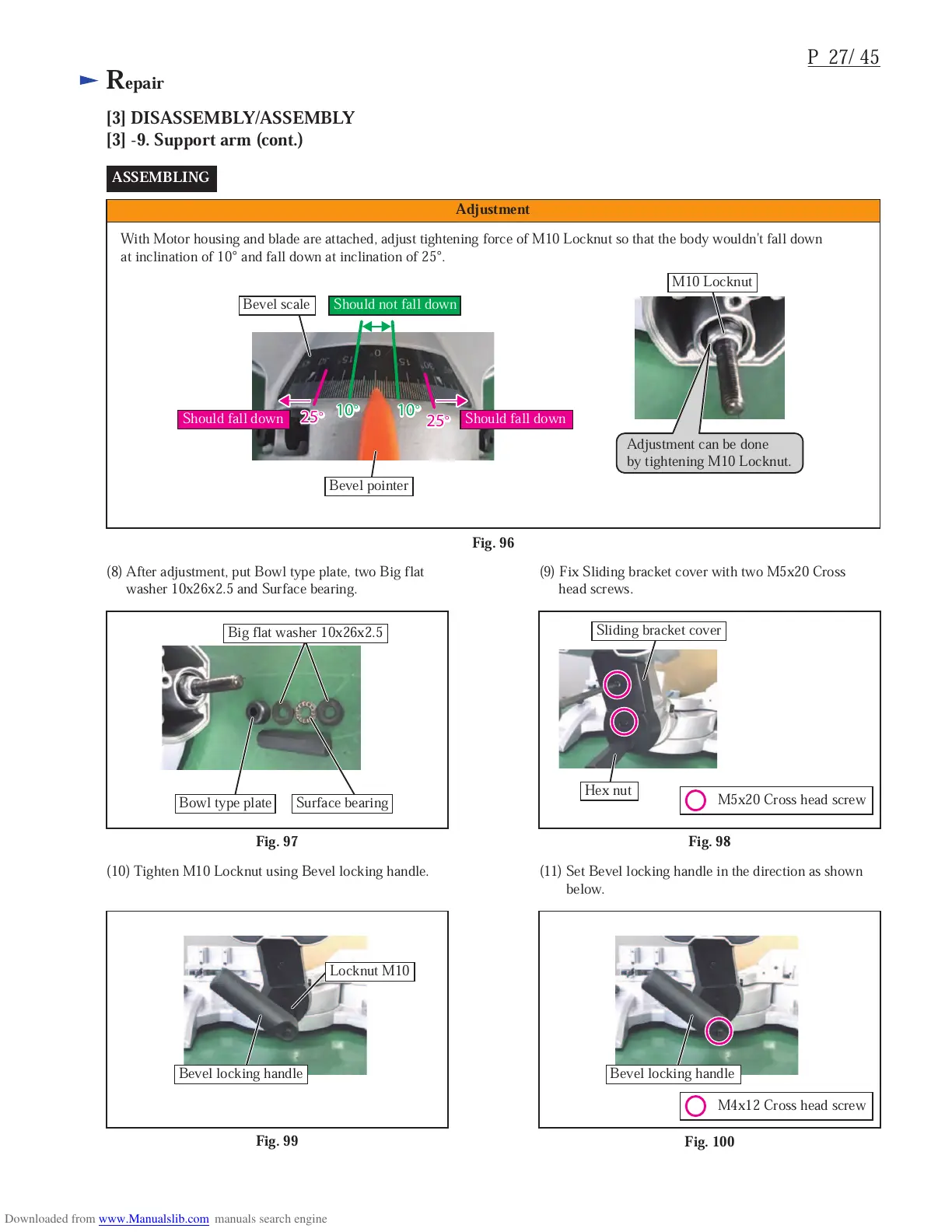

With Motor housing and blade are attached, adjust tightening force of M10 Locknut so that the body wouldn't fall down

at inclination of 10° and fall down at inclination of 25°.

ASSEMBLING

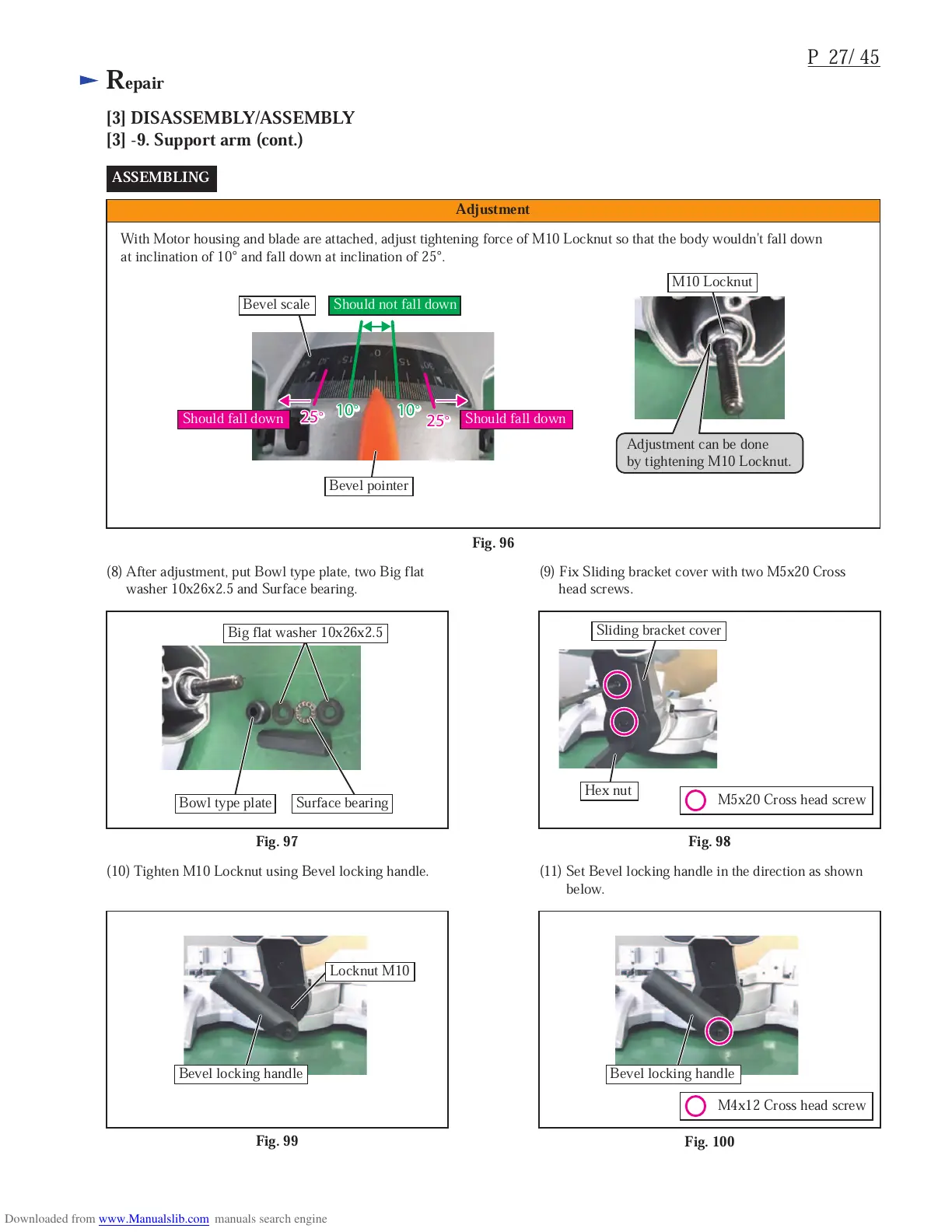

Fig. 97

Fig. 98

(8) After adjustment, put Bowl type plate, two Big flat

washer 10x26x2.5 and Surface bearing.

(9) Fix Sliding bracket cover with two M5x20 Cross

head screws.

Bevel scale

M10 Locknut

Bowl type plate

Big flat washer 10x26x2.5

Surface bearing

Bevel locking handle

Hex nut

Sliding bracket cover

M5x20 Cross head screw

M4x12 Cross head screw

Fig. 99

Fig. 100

(10) Tighten M10 Locknut using Bevel locking handle.

Locknut M10

Bevel locking handle

(11) Set Bevel locking handle in the direction as shown

below.

Adjustment can be done

by tightening M10 Locknut.

Fig. 96

Adjustment

Should not fall down

Should fall downShould fall down

10

°

25

°

25

°

10

°

10

°

25

°

25

°

10

°

Bevel pointer

Loading...

Loading...