CRANKMECHANISM

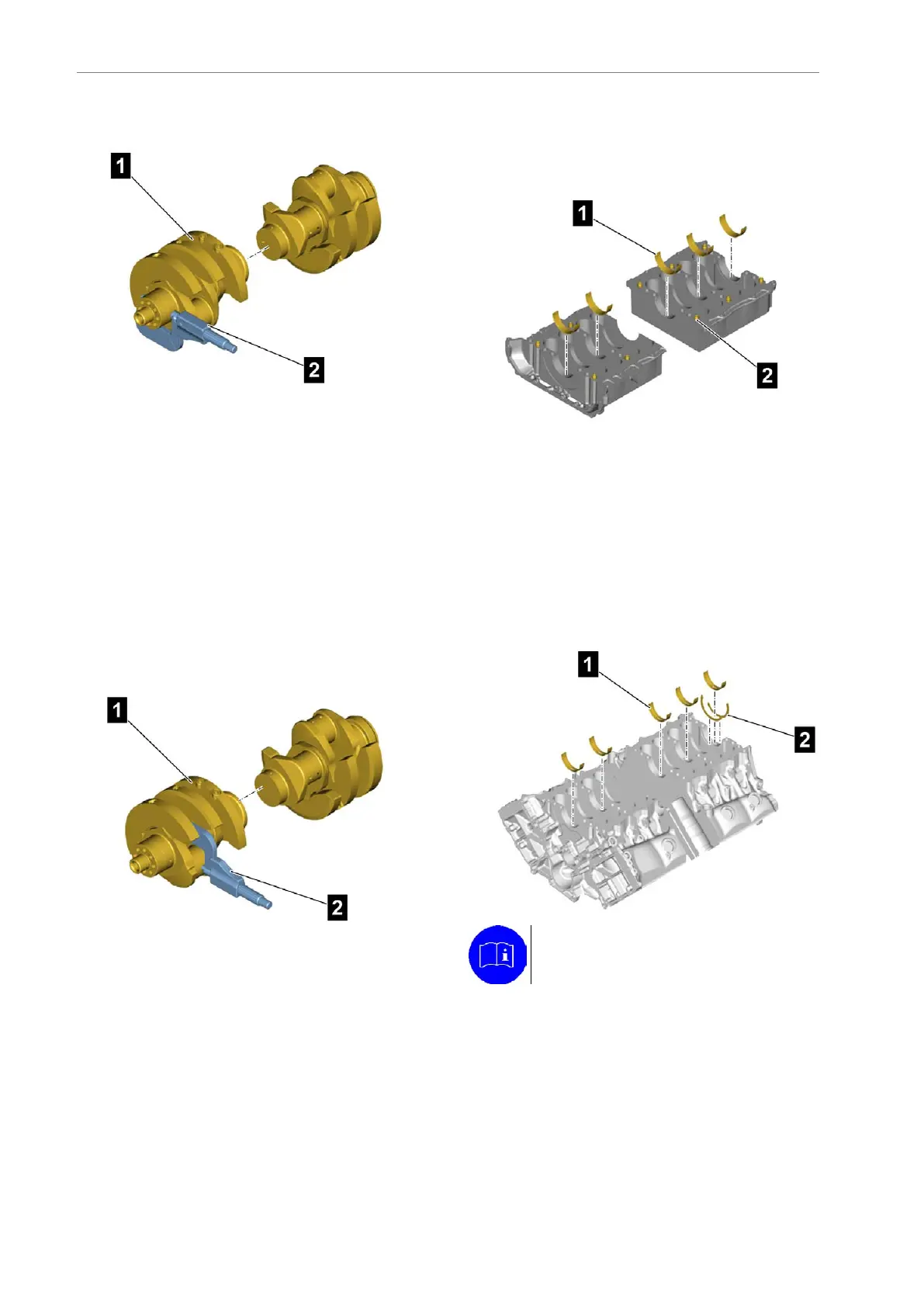

Checkingthemainbearingjournal

•Cleanthemainbearingjournalofthe

crankshaft(1)

•Measurethemainbearingjournalofthe

crankshaft(1)usingamicrometer(2)

•Repeatthemeasurementforeachmainbearing

journal

Thedimensionsofthecrankshaftbearingjournals

mustbewithinthespeciedtolerances,Ø111.966

–111.988mm.

Fitanewcrankshaftifthedimensionsareoutof

tolerance

Checkingtheconnectingrodbearingjournal

•Cleanthecrankshaft(1)

•Measuretheconnectingrodbearingjournalusing

amicrometer(2)

•Measuretheconnectingrodbearingjournalat

severalpoints

•Repeatthemeasurementforeachconnectingrod

bearingjournal

•Thepermittedconnectingrodbearingjournal

diameterisØ95.966–95.988mm

Fitanewcrankshaftifthedimensionsareoutof

tolerance

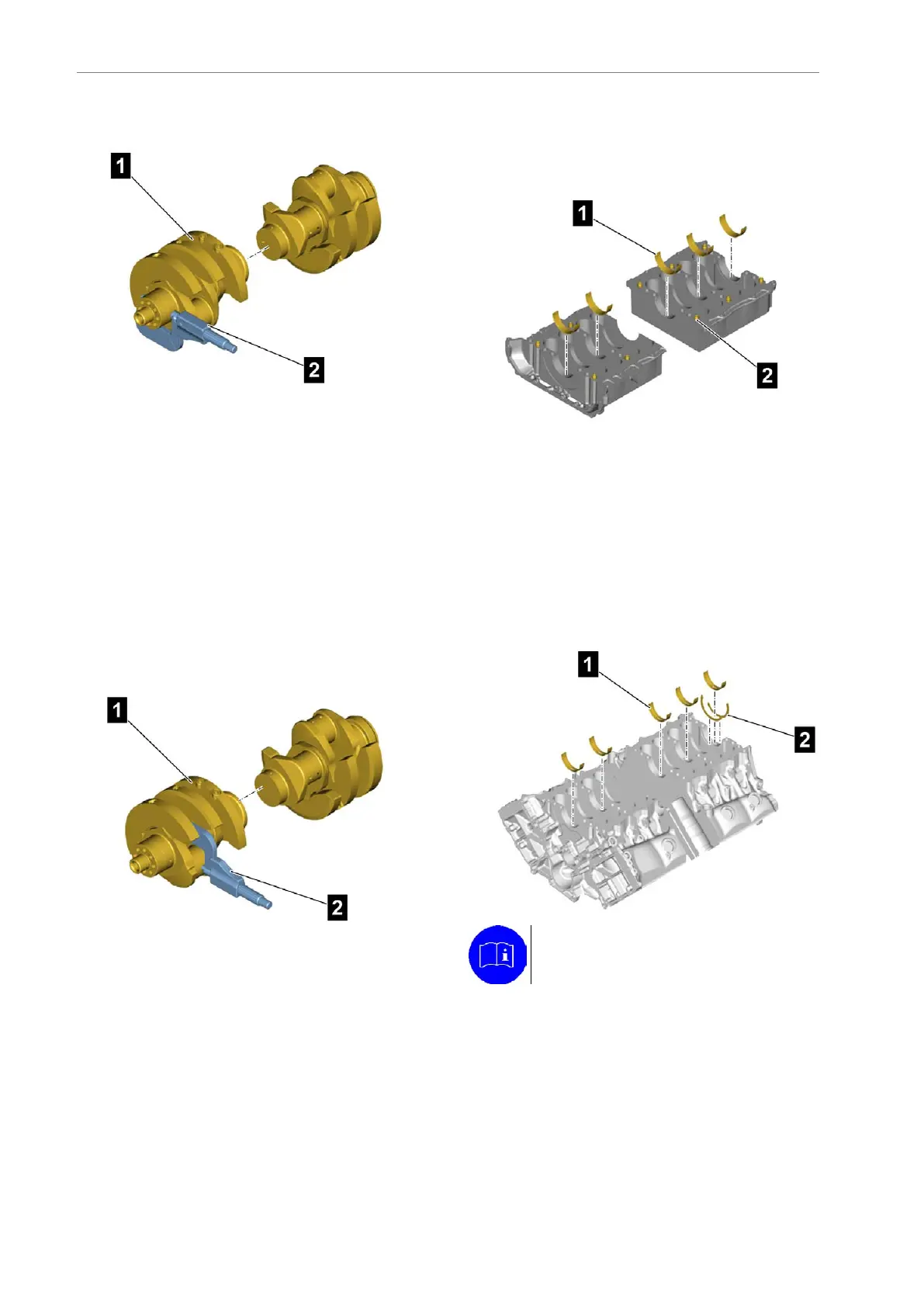

Installingthecrankshaft

Insertingthemainbearingshellsintothe

crankcaselowersection

•Checknoneofthettedsleeves(2)aremissing;

10items,V12enginehas14items

•ThinlyapplycleanengineoiltoMANStandard

3277onthemainbearingshells(1)

•Insertthemainbearingshells(1)intothebearing

seatsasmarkedandalignwiththeSetting

tool[149]

Insertingthemainbearingshellsintothe

crankcase

Note

Onlyusethrustwasherswiththesame

wallthickness.

•Insertthecleanedmainbearingshells(1)intothe

bearingseatsonthecrankcaseasmarkedand

alignwiththeSettingtool[149]

•LightlyapplycleanengineoiltoMANStandard

3277onthemainbearingshells(1)

•Determinethethrustwashers(2)tobeused,see

Checkingthecrankshaftaxialplay,340

•ThinlyapplycleanengineoiltoMANStandard

3277onthecleanedthrustwashers(2)

•Insertthethrustwashers(2)intothenalbearing

seatasmarked,withtheoilgroovesfacingthe

crankshaft

346AE63stedition

Loading...

Loading...