OM Centrif Micro ΙΙ-5 35

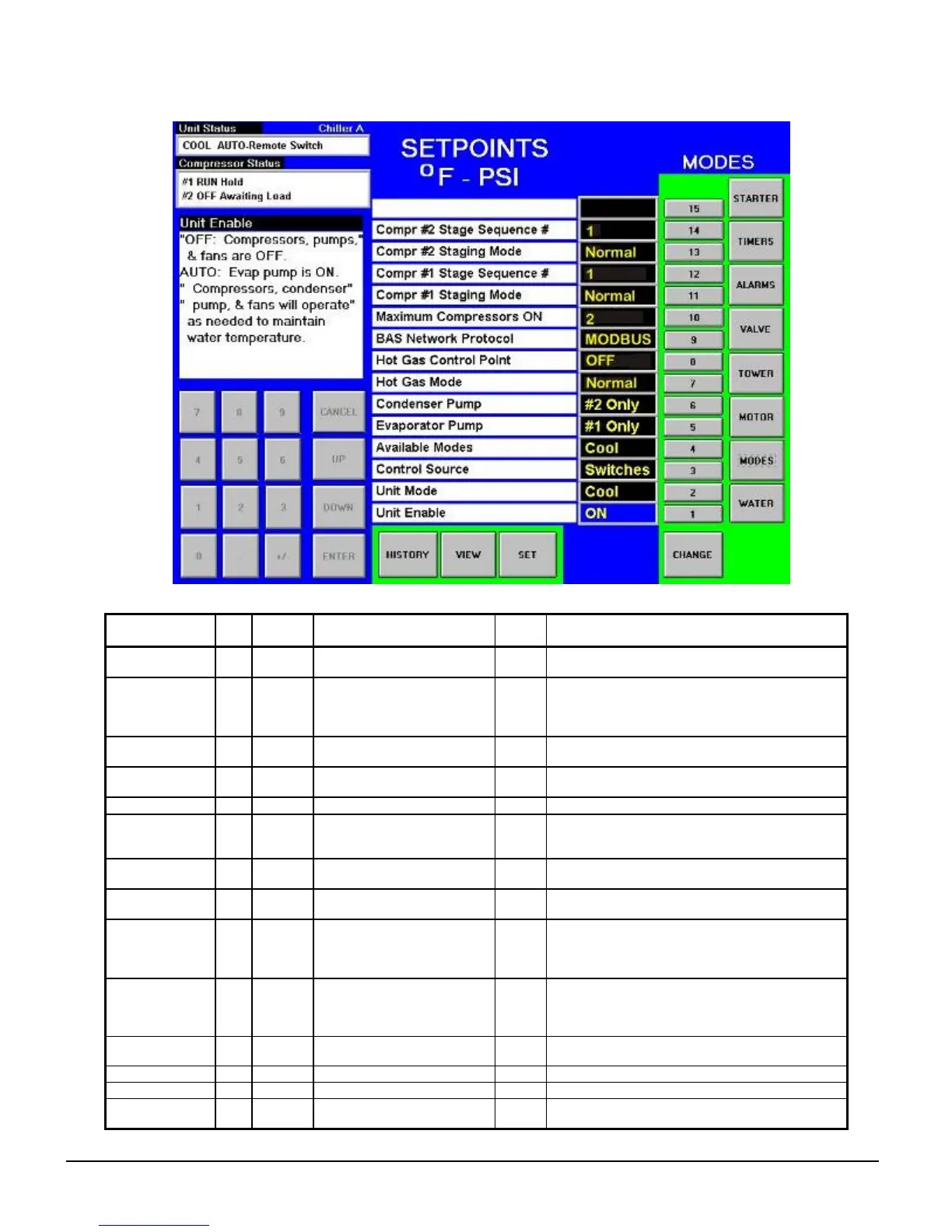

MODES Setpoints

Figure 20, MODES Setpoint Screen

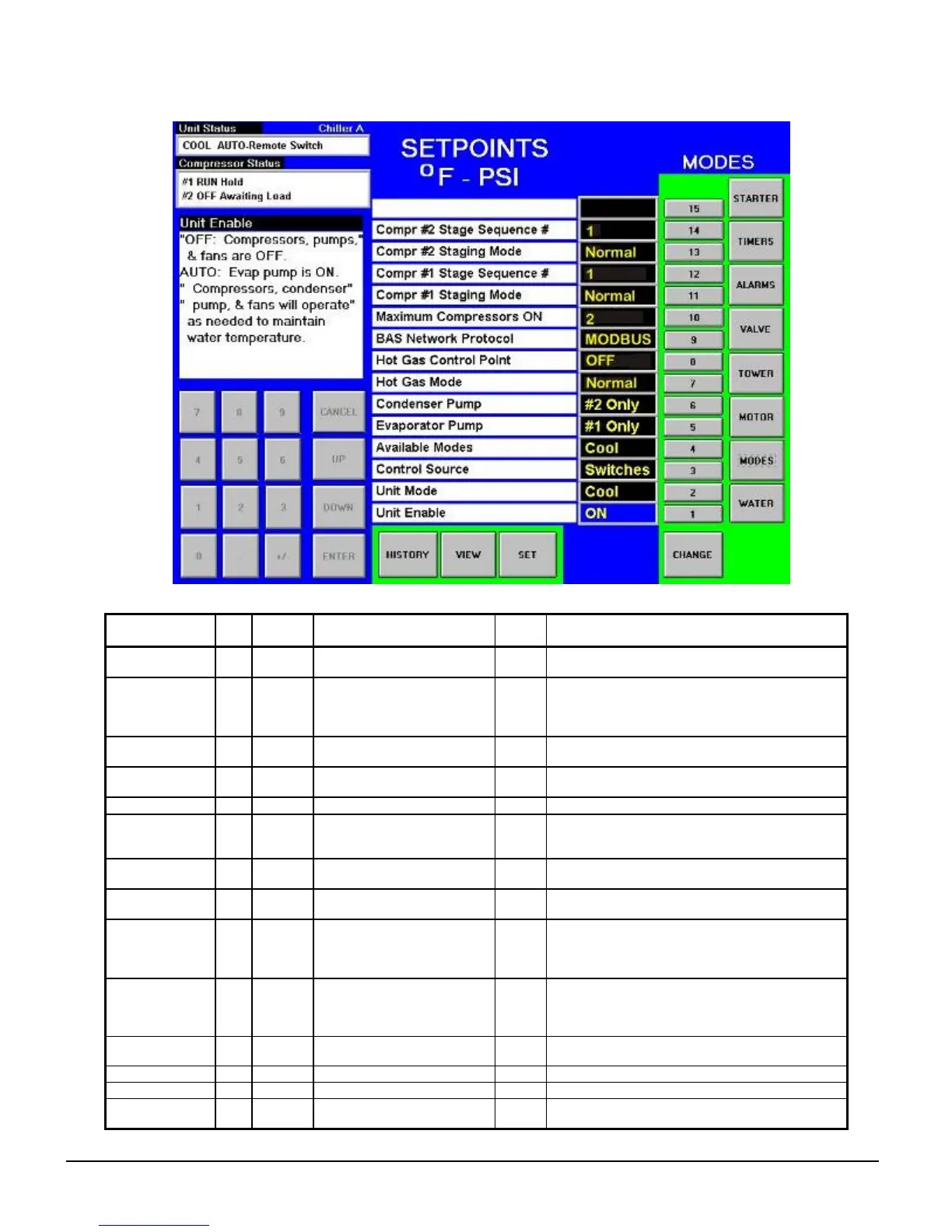

Table 18, MODE Setpoint Settings

Description No. Default Range

Pass-

word

Comments

Comp # 2 Stage

Sequence

14 1 1,2, … (# of Compressors) M

Sets sequence number for # 2 compressor, if 1 it is

always first to start, if 2 is always second (Note 1)

Comp # 2 Mode 13 Normal

Normal, Efficiency, Pump,

Standby

M

Normal uses standard sequencing

Efficiency starts one compressor on each dual unit

Pump starts all compressors on one chiller first

Standby uses this compressor only if another fails.

Comp #1 Stage

Sequence

12 1 1,2, … (# of Compressors) M

Sets sequence number for # 1 compressor, if 1 it is

always first to start, if 2 is always second (Note 1)

Comp #1 Mode 11 Normal

Normal, Efficiency, Pump,

Standby

M Ditto No. 12.

Max. Comp. ON 10 1 1-16 M Total number of compressors minus standby

BAS Protocol 9 Modbus

None, Local, Remote,

BACnet, LonWorks,

MODBUS,

M

Sets BAS Standard Protocol to be used or LOCAL

if none.

Hot Gas Control

Point

8 30% 20 to 70% T LWT or % RLA below which HGBP solenoid is on

Hot Gas Bypass

Mode

7 Normal Off, Water LWT, %RLA T Sets mode for hot gas operaton

Cond Pump 6

Pump

#1 Only

Pump #1 Only, Pump #2

Only, Auto Lead, #1 Primary,

#2 Primary

M

Pump #1 Only, Pump #2 Only, use only these

pumps

AUTO, balance hours between #1 and #2

#1 Primary, #2 Primary, if primary fails, use other

Evap Pump 5

Pump

#1 Only

Pump #1 Only, Pump #2

Only, Auto Lead, #1 Primary,

#2 Primary

M

Pump #1 Only, Pump #2 Only, use only these

pumps

AUTO, balance hours between #1 and #2

#1 Primary, #2 Primary, if primary fails, use other

Available Modes 4 COOL

COOL, COOL/ICE, ICE,

COOL/HEAT, HEAT

T Sets modes that can be selected in SP 2

Control Source 3 LOCAL LOCAL, BAS, SWITCH O Sets control source

Unit Mode 2 COOL COOL, ICE, HEAT, TEST Selects from MODES in SP4

Unit Enable 1 OFF OFF, ON O

OFF, everything is off. ON, Evap pump on, comp,

cond pump and tower on as required to meet LWT

Loading...

Loading...