82 OM Centrif Micro ΙΙ-5

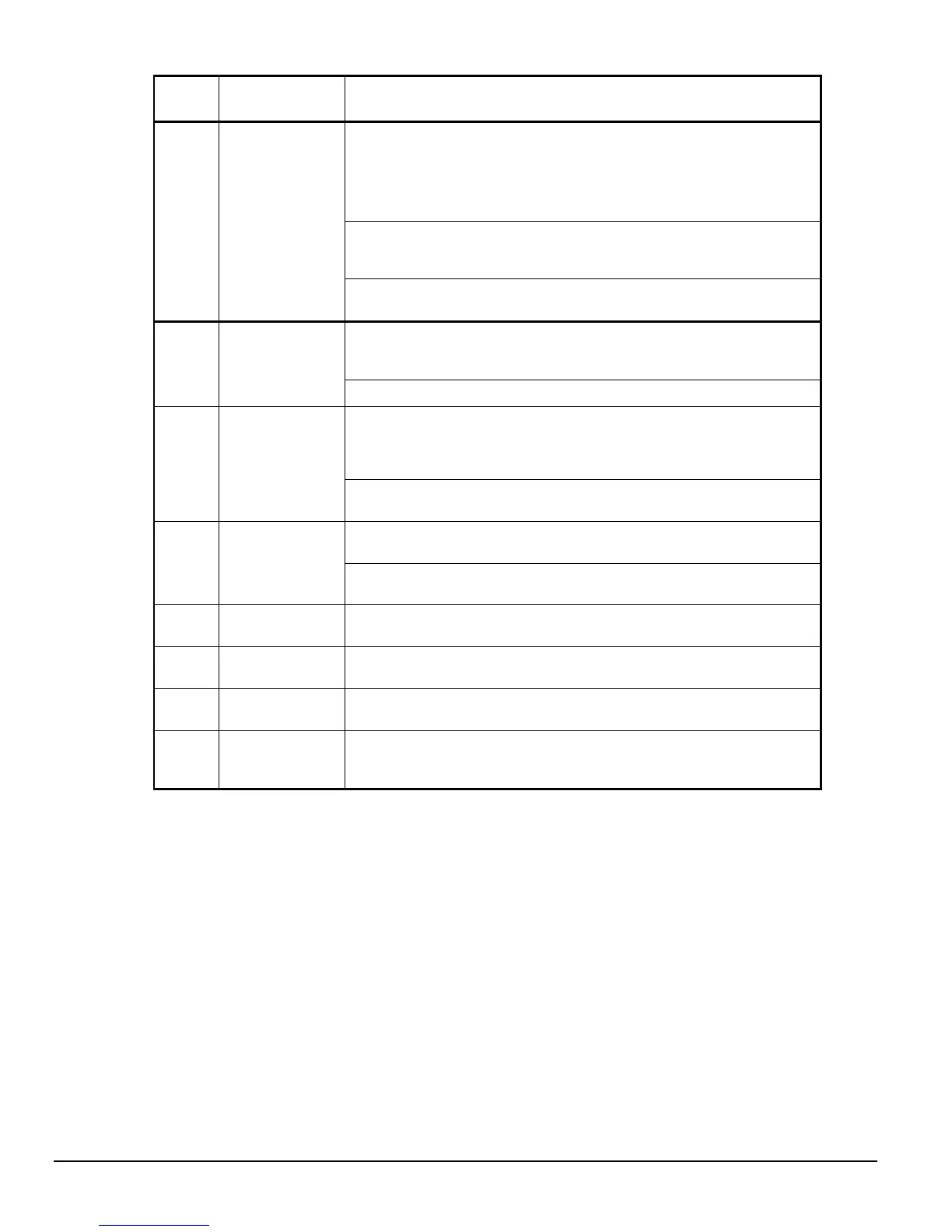

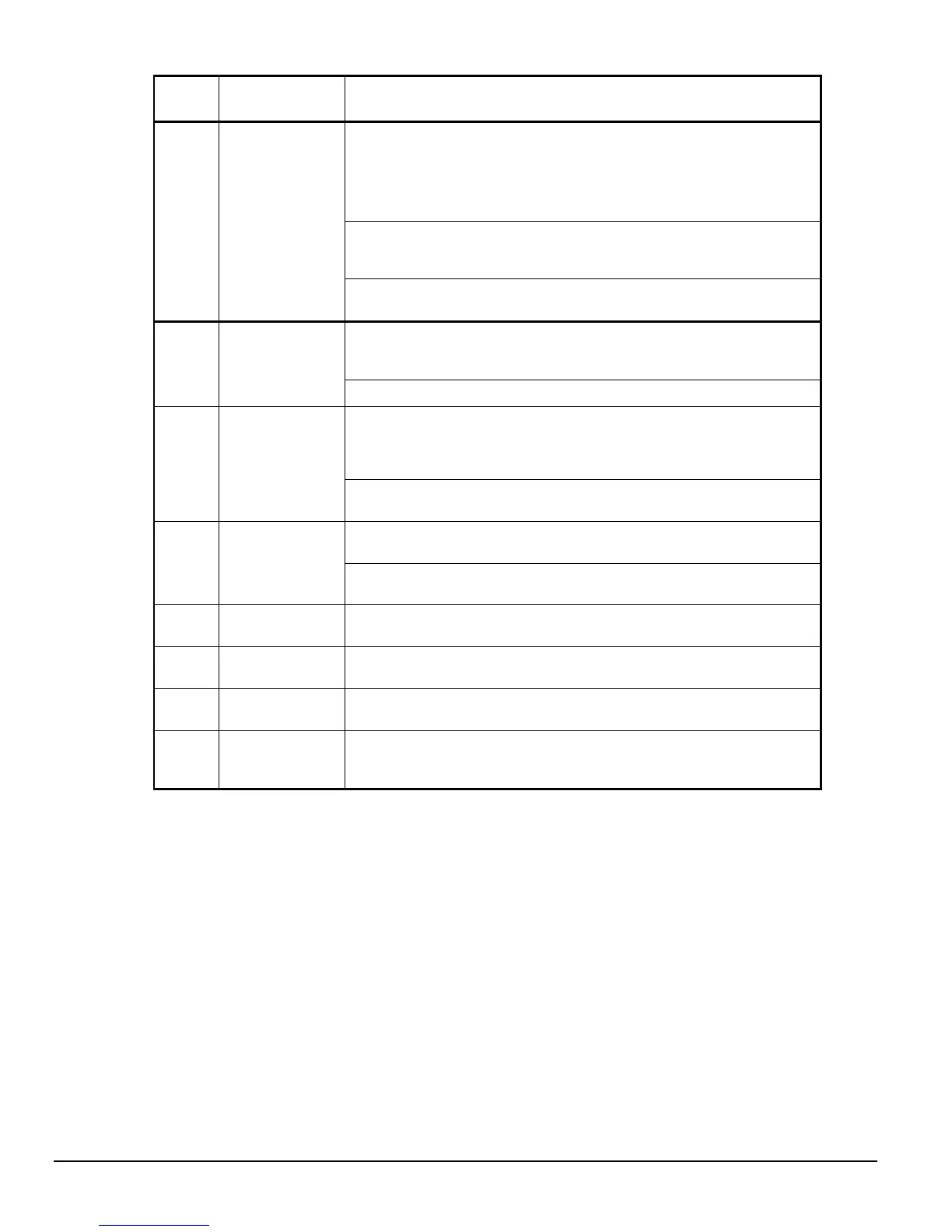

Fault

Code

Description Detailed Description of Fault / Possible Solutions

Indicates that communication has been lost with a remote device such as

a remote keypad.

(This fault will normally occur if the remote keypad is disconnected while

the D3 control board is powered up. Only connect and disconnect a

remote keypad when the control power is off.)

Verify that the remote keypad cable has not been damaged and that its

connectors are firmly seated at both the keypad and the D3 Control

board.

F81

SPI

Communication

Fault

Route keypad cables away from high power and/or high noise areas to

reduce possible electrical noise pickup.

Indicates that the starter has lost serial communications. Fault occurs

when the starter has not received a valid serial communications within

the Communication Timeout parameter (FUN 12, P59) defined time.

F82

Modbus Timeout

Fault

Examine remote system for cause of communication loss.

Typically occurs when attempting to run a version of control software that

is incompatible with the D3 control board hardware being used. Verify

that the software is a correct version for the D3 control board being used.

Consult factory for more details.

F94

CPU Error – SW

fault

Fault can also occur if the D3 control has detected an internal software

problem. Consult McQuayService.

The non-volatile user parameter values have been found to be corrupted.

Typically occurs when the D3 control is re-flashed with new software.

F95

CPU Error –

Parameter

EEPROM

Checksum Fault

If fault persists after performing a Factory Parameter reset, consult

McQuay Service.

F96 CPU Error

The D3 control has detected an internal CPU problem. Consult McQuay

Service.

F97

CPU Error – SW

Watchdog Fault

The D3 control has detected an internal software problem. Consult

McQuay Service.

F98 CPU Error

The D3 control has detected an internal CPU problem. Consult McQuay

Service.

F99

CPU Error –

Program EPROM

Checksum Fault

The non-volatile program memory has been corrupted.

Preventive Maintenance

During Commissioning

• Torque all power connections during commissioning, including pre-wired equipment.

• Check all control wiring for loose connections.

After First Month of Operation

• Re-torque all power connections, including pre-wired equipment annually.

• Clean accumulated dust with clean compressed air.

• Inspect cooling fans every three months.

• Clean or replace air vent filters every three months.

Loading...

Loading...