12 Pause times

67

12 Pause times

Frequency of sterilization

Pause times between the individual programs are not necessary, as the sterilization chamber is main-

tained permanently at the same temperature. After the end/abort of the drying time and removal of the

sterilized equipment, you can load the steam sterilizer again and start a new program.

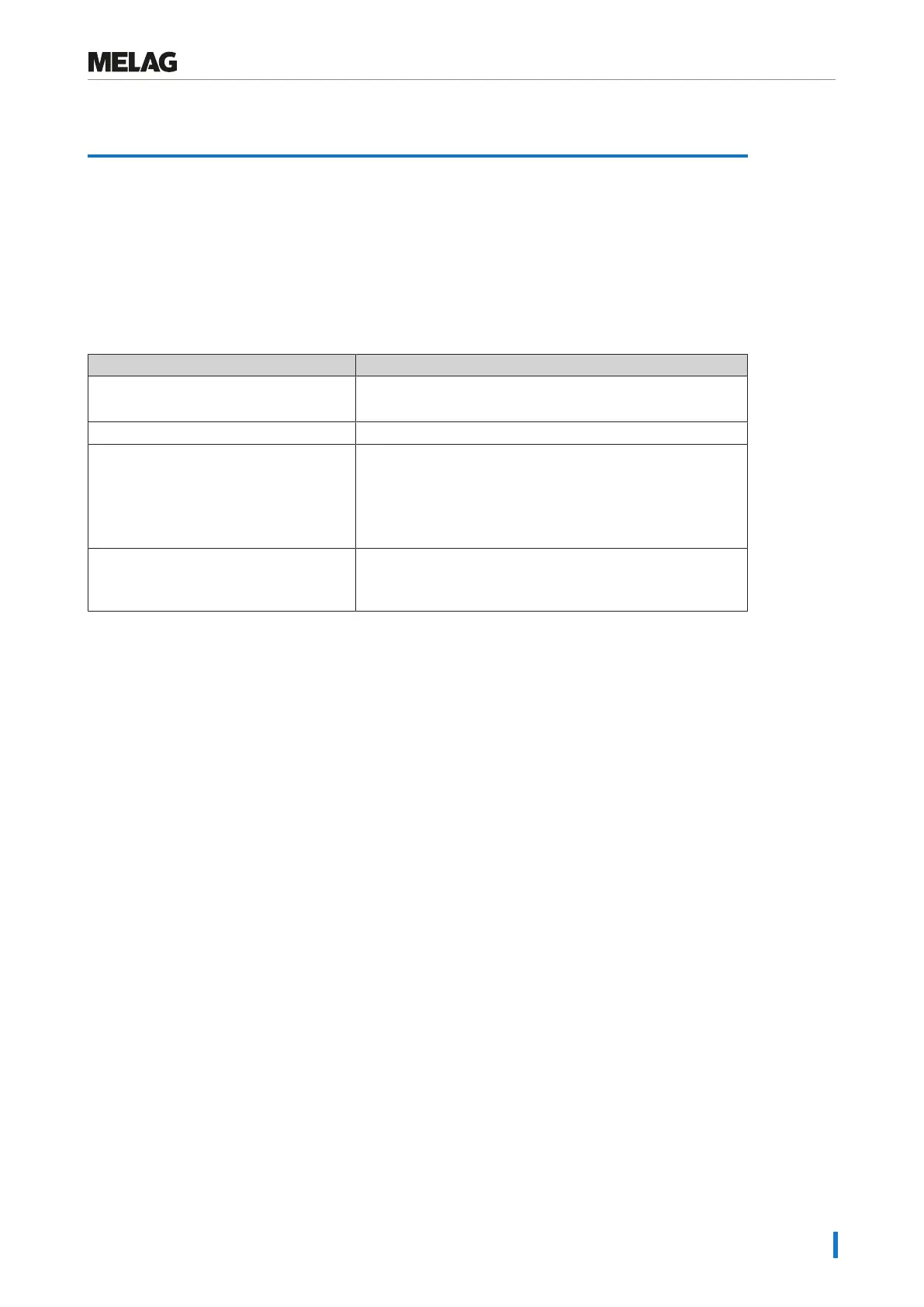

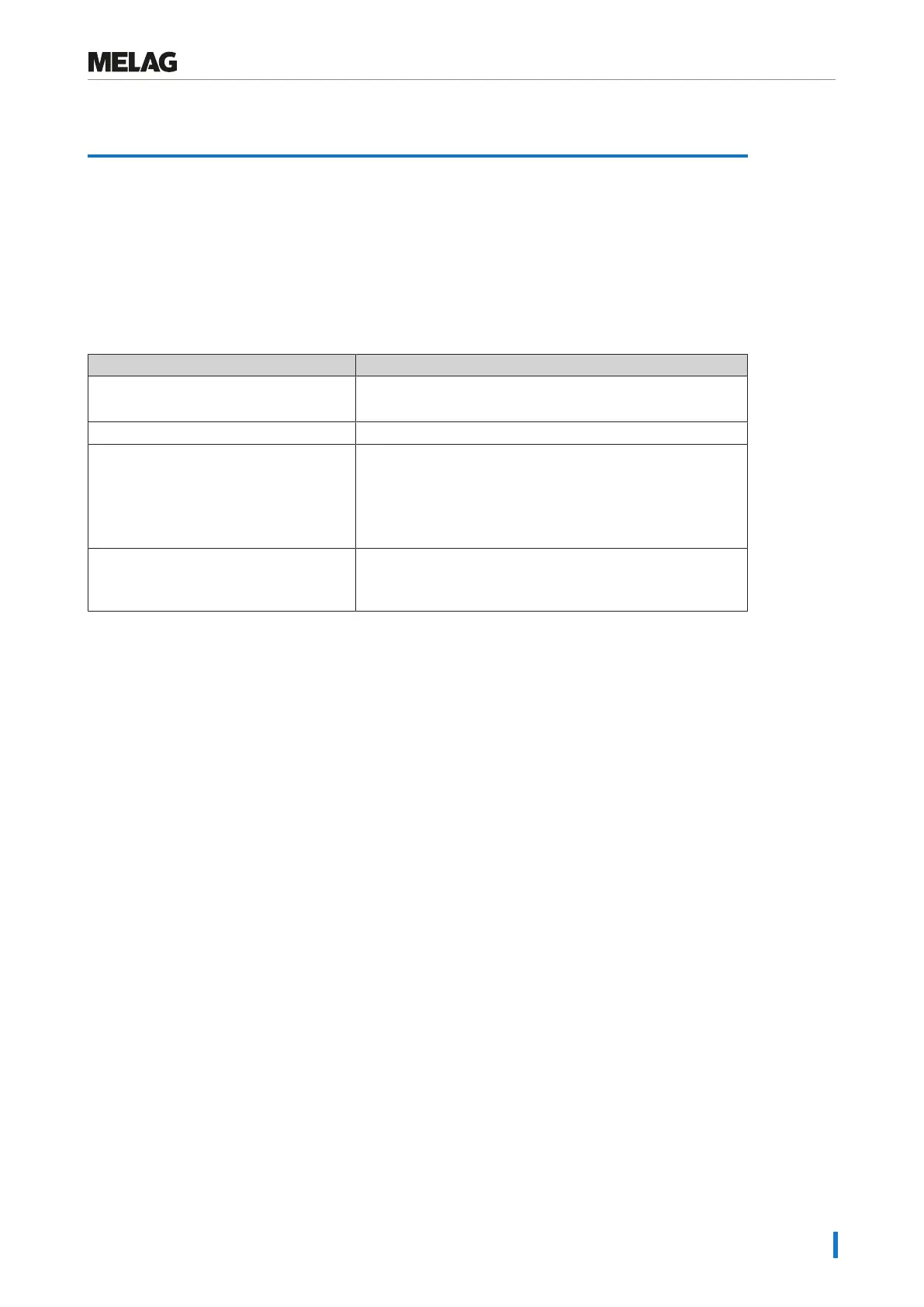

Duration of the operating pause

Duration of the operating pause Measure

Short pauses between two sterilization

processes

▪ Keep the door closed to save energy

▪ Set the energy-saving mode correspondingly

Pauses which last longer than an hour ▪ Switch off the steam sterilizer

Longer pauses e.g. over night or the

weekend

▪ Open the door and switch off the steam sterilizer

▪ Leave the door ajar to prevent premature wear and the

sticking of the door seal

▪ If present, shut off the water inflow of the water treatment

unit

Longer than two weeks ▪ Perform a vacuum test

▪ After a successful vacuum test, perform an empty

sterilization run in Quick-Program S

After pauses, perform the checks described in chapter Function tests [}page42] depending on the length

of pause.

Decommissioning

When decommissioning the steam sterilizer for a long pause (e.g. due to holiday), proceed as follows:

1. Empty the double jacket steam generator, see Emptying the double jacket [}page67].

2. Switch off the steam sterilizer at the power switch.

3. Disconnect the power plug from the socket and if necessary, allow the steam sterilizer to cool.

4. Empty the internal storage tank.

5. Shut off if present, the water inflow of the water treatment unit.

Emptying the double jacket

You have the option of draining the water in the double jacket steam generator easily via program Drain. In

order to do so, the steam sterilizer is heated once, building up pressure in the double-jacket so that the

water can be drained fully from the double jacket steam generator.

1. Switch on the steam sterilizer at the power switch.

Loading...

Loading...