Transmission and Drive Line

90-863758060 AUGUST 2006 Page 2A-3

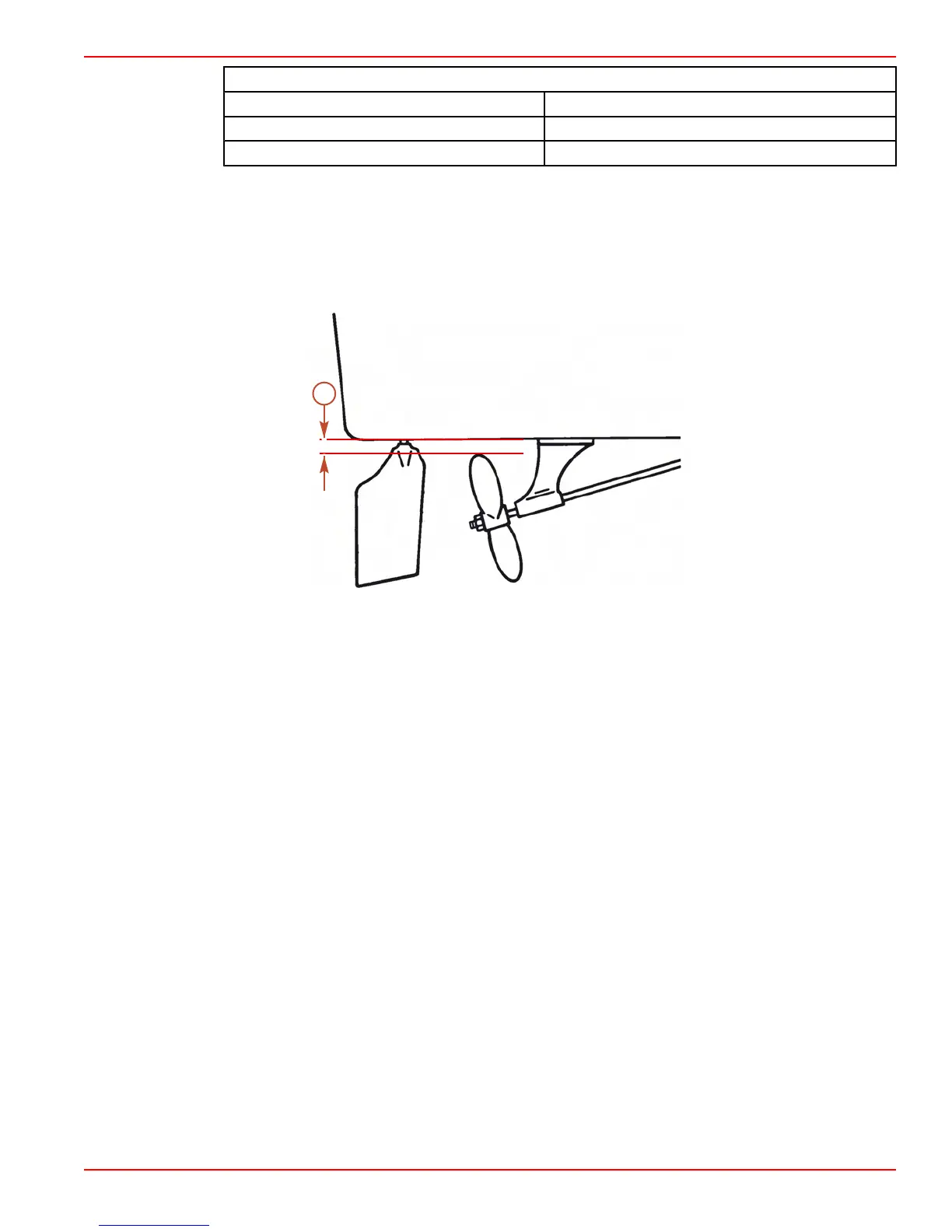

Minimum Distance Between Engine Centerlines

Model Measurement

All Except 8.1S 838 mm (33 in.)

8.1S 927 mm (37½ in.)

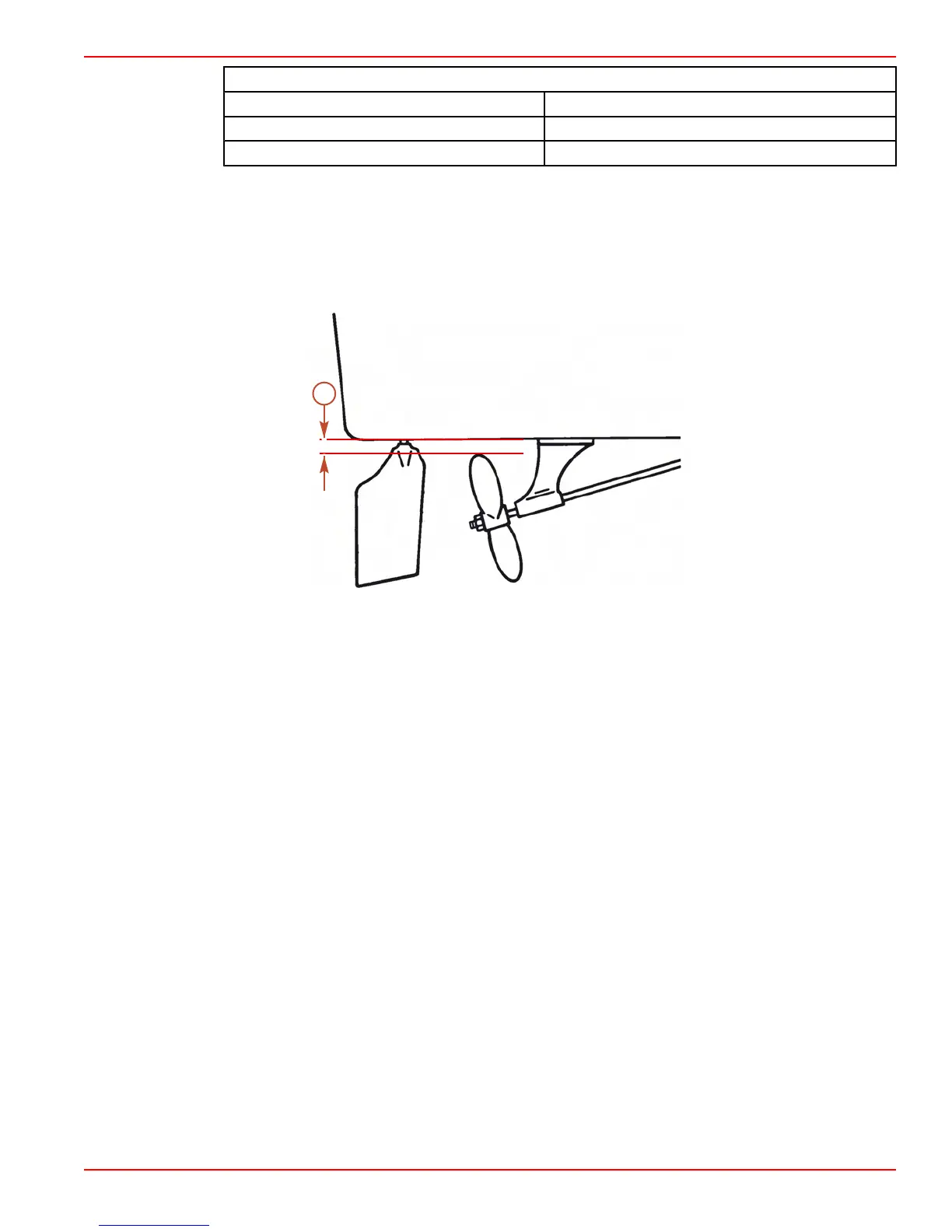

Propeller Blade Tip Clearance

Sufficient clearance is required between the propeller blade tips and the boat bottom to

prevent a water-hammering action against the hull. Insufficient clearance will contribute to

excessive noise and vibration and could result in cavitation problems. A clearance of 10–

15% of the propeller diameter is typical for most boats.

a

14885

a - 10–15% of propeller diameter minimum

Propeller Shaft Coupling

Since the engine has flexible mounts, some provision must be provided in the propeller

shaft and coupling to accommodate for slight engine movement. On recreational boats,

this is typically provided by the use of a flexible stuffing box and a single strut bearing. In

these cases, a rigid propeller shaft coupling can be used. Rigid propeller shaft couplings

can be ordered with the engine or purchased through Mercury Precision Parts and

Accessories. Alignment with these couplings is critical; See Section 3 — Engine.

Typically, a minimum distance of 20 times the propeller shaft diameter should be provided

between the transmission output flange and the first fixed bearing to minimize vibration. If

this distance is not available, a flexible coupling can be used. Flexible couplings provide

vibration isolation and are more tolerant to engine misalignment. They also reduce the need

for periodic realignment of the engine.

If an aftermarket coupling is to be used, the flange must conform with the specifications on

the installation drawing. The transmission output flanges comply with:

• Velvet Drive 71C and ZF 45C—SAE J756 Type 410.

• All other transmissions—SAE J756 Type 5.

All coupler bolts must be SAE Grade 8 (Metric Grade 10.9) or better, with a shoulder (grip

length) long enough to pass through the coupler and transmission output flange. All coupler

bolts must be torqued.

Loading...

Loading...