Section 5 - Maintenance

90-8M0069751 eng APRIL 2012 Page 103

3. Torque the propeller nut.

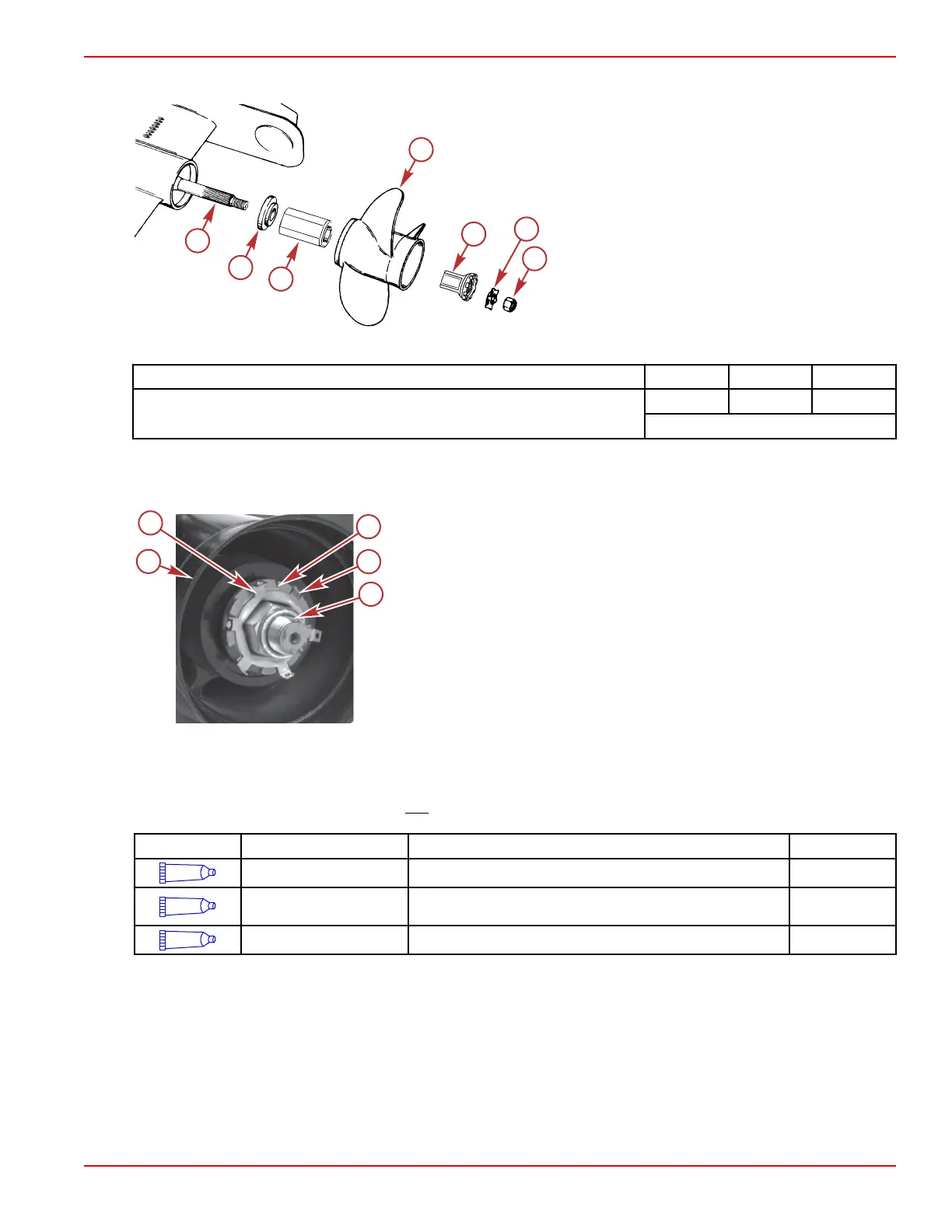

Typical Bravo One models

a - Propeller shaft splines

b - Forward thrust hub

c - Flo‑Torque II drive hub

d - Propeller

e - Drive sleeve adapter

f - Tab washer

g - Propeller nut

NOTE: The propeller torque stated is a minimum torque value.

Description

Nm lb–in. lb–ft

Bravo One propeller nut

75 – 55

Then align tabs with grooves

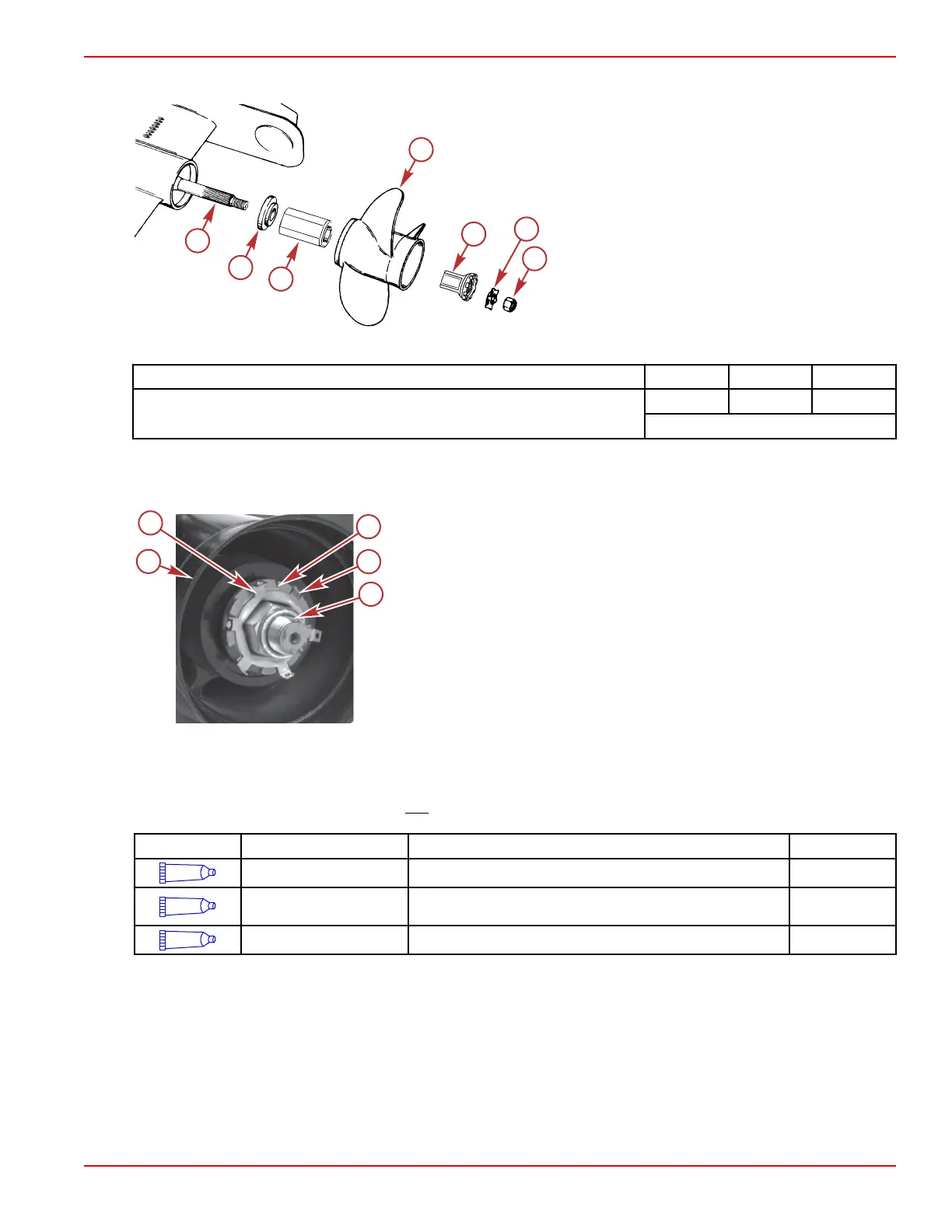

4.

Models equipped with the tab washer: Continue to tighten the propeller nut until the three tabs on the tab washer align

with the grooves on the spline washer.

5. Bend the three tabs down into the grooves.

a - Prop

b - Tab washer

c - Drive sleeve adapter

d - Tab bent down

e - Propeller nut

Bravo Two Models

IMPORTANT: Use the correct rotation propeller. The propeller rotation MUST match the direction of rotation of the propeller

shaft.

1. Liberally coat the propeller shaft spline with one of the following Quicksilver lubricants.

Tube Ref No.

Description Where Used Part No.

34

Special Lubricant 101 Propeller shaft splines 92-802865Q02

95

2-4-C Marine Lubricant

with PTFE

Propeller shaft splines 92-802859A 1

94

Anti-Corrosion Grease Propeller shaft splines 92-802867Q 1

NOTE: Anti‑corrosion grease is for saltwater applications only.

2. Install the propeller with the attaching hardware as shown.

Loading...

Loading...