38

|

VIKING / VIKING COMBI

Rev. 2.0 (1.8.2017)

Installation

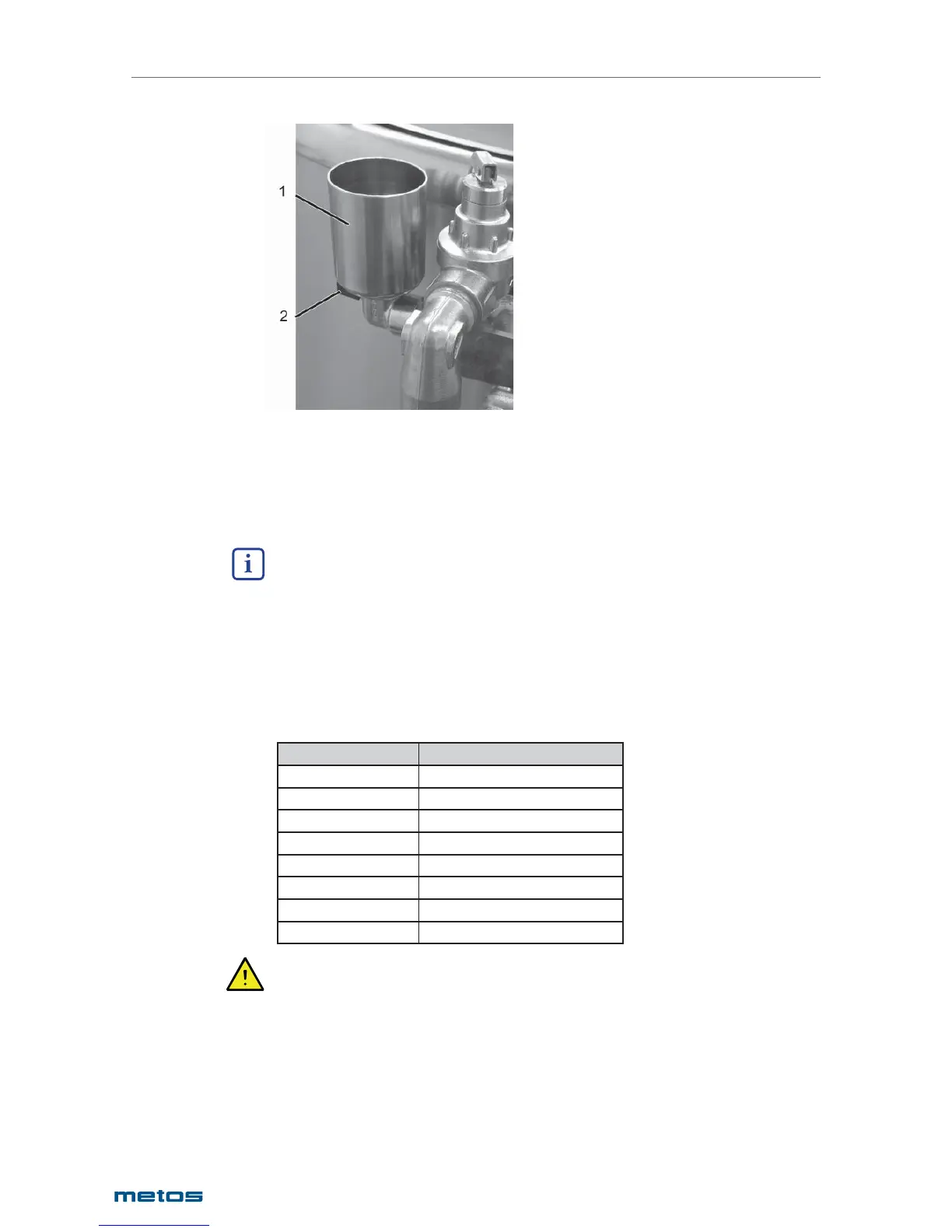

1. Water inlet funnel

2. Handle of the water inlet valve

• Open the water inlet valve, which is under the water inlet funnel, by turning the handle parallel to the valve.

• Let water into the water inlet funnel. Stop fi lling water when water starts to drop out of the control valve.

• Close the water inlet valve. Close the control valve when water has stopped running out of it. Now the

steam generator is fi lled up to the maximum level.

Overfi lling might prevent proper warming of the kettle. Thanks to the steam condensing system, the

steam generator requires fi lling only a few times per year. Depending on the use of the kettle, it will be

2-4 times per year. If the kettle is often used at low temperatures less than 100°C, water must be added

to the steam generator more frequently. This is caused by the closing temperature of the automatic

vacuum valve.

A white water level indicator light on the control panel displays when water must be added to the steam

generator. When the indicator light illuminates, the kettle does not warm up. This protects the heating

elements. Add water according to the instructions. The indicator light switches off, when the minimum

water level has been reached. Water is needed in the steam generator as follows:

Model

Viking 40 14 l

Viking 60 14 l

Viking 80 15 l

Viking 100 15 l

Viking 150 21 l

Viking 200 21 l

Viking 300 37 l

Viking 400 37 l

Do not leave the control valve of the steam generator, the safety valve and the water inlet valve open

when the kettle heating is on. The discharging steam might cause burns or other damage.

Preventing the scale build-up

Hard or otherwise low-quality water can cause scale or other build-ups on the heating elements. The

build-up can damage or destroy the heating elements. Under bad water conditions, use of purifi ed wa-

ter is recommended for the steam generator in order to protect the boiler and heating elements from

damage.

Loading...

Loading...