10 3 R 74 en

Check that the spring angles extend to the control

face.

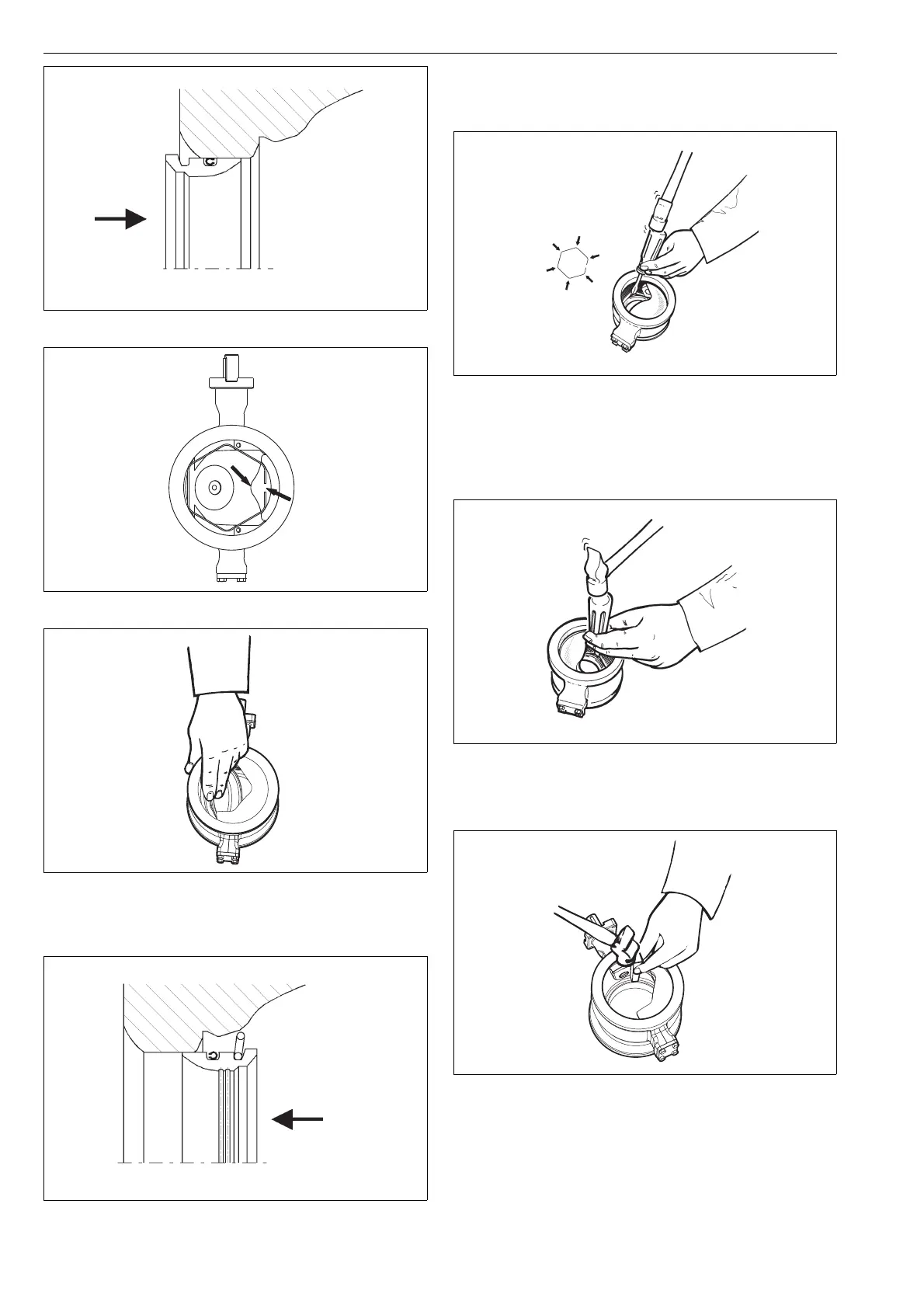

Place a screwdriver on each visible spring angle one

after the other and knock the spring into the groove,

see Fig. 29.

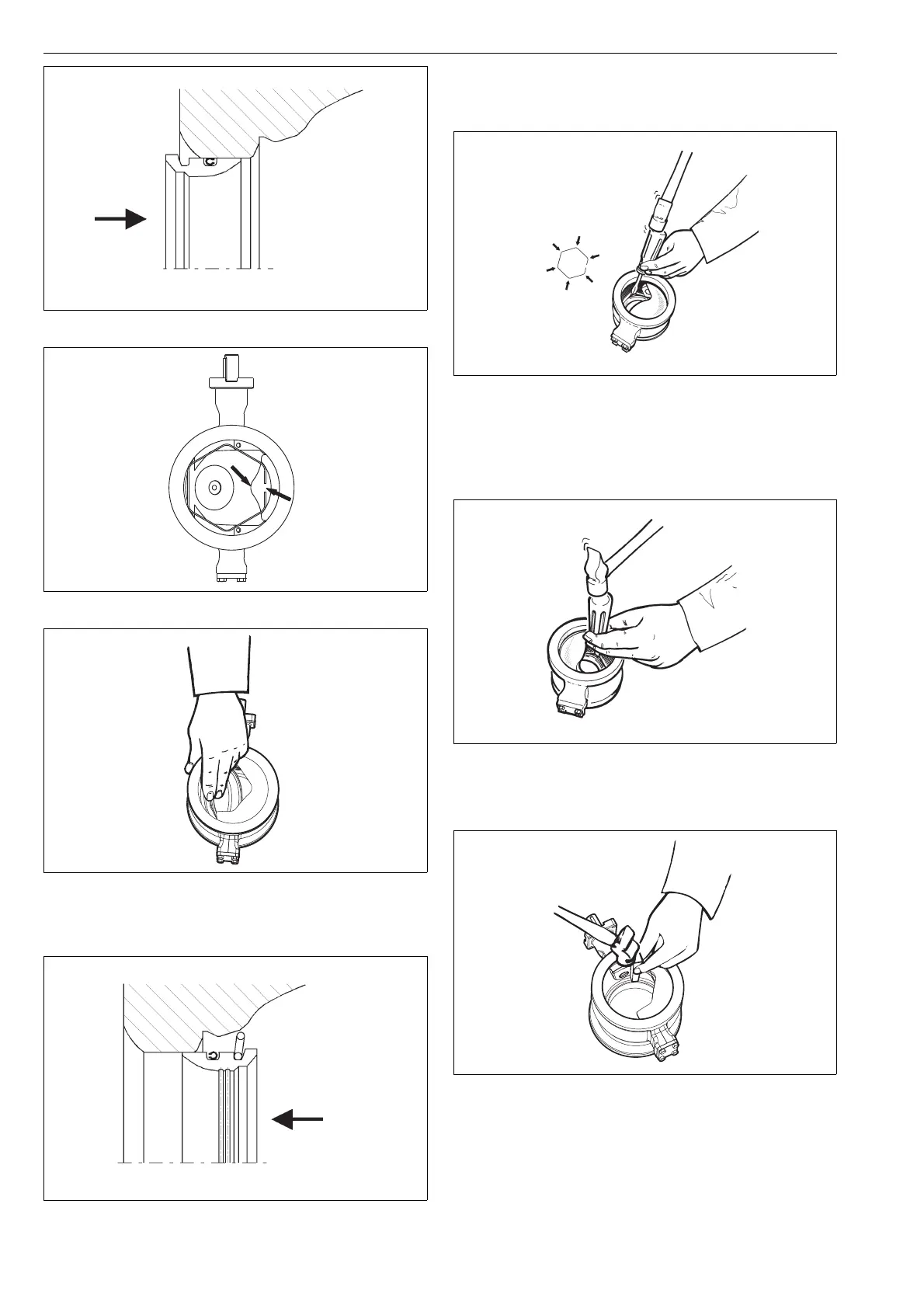

Turn the segment 180° clockwise and knock the rest

of the spring angles into the groove, Fig. 30. A spe-

cial tool available from the manufacturer may also

be used for the work phases in Figs. 29 and 30.

Use a plastic spindle to ensure that the seat is cor-

rectly placed and can move freely, Fig. 31.

4.6 Dismantling the valve

Turn the valve into the closed position.

Remove the pin lockings either by grinding or using

a spindle. Detach the pins (14 and 15) by drilling, Fig.

32. Be careful not to damage the original bores.

Note! The pins and the drive shaft have been

Fig. 25 Precompression of the lip seal

Fig. 26 Mounting the seat

Fig. 27 Slipping the seat into the body

Fig. 28 Pushing the the spring angles against the control

face

Fig. 29 Knocking the spring into the groove

Fig. 30 Knocking the spring after turning the seat around

Fig. 31 Securing with a plastic spindle

Loading...

Loading...