3 R 74 en 11

secured by welding in the titanium version and in

the acid-resistant high-consistency version S.

Detach the retainer plates (30).

Detach the gland packings (20).

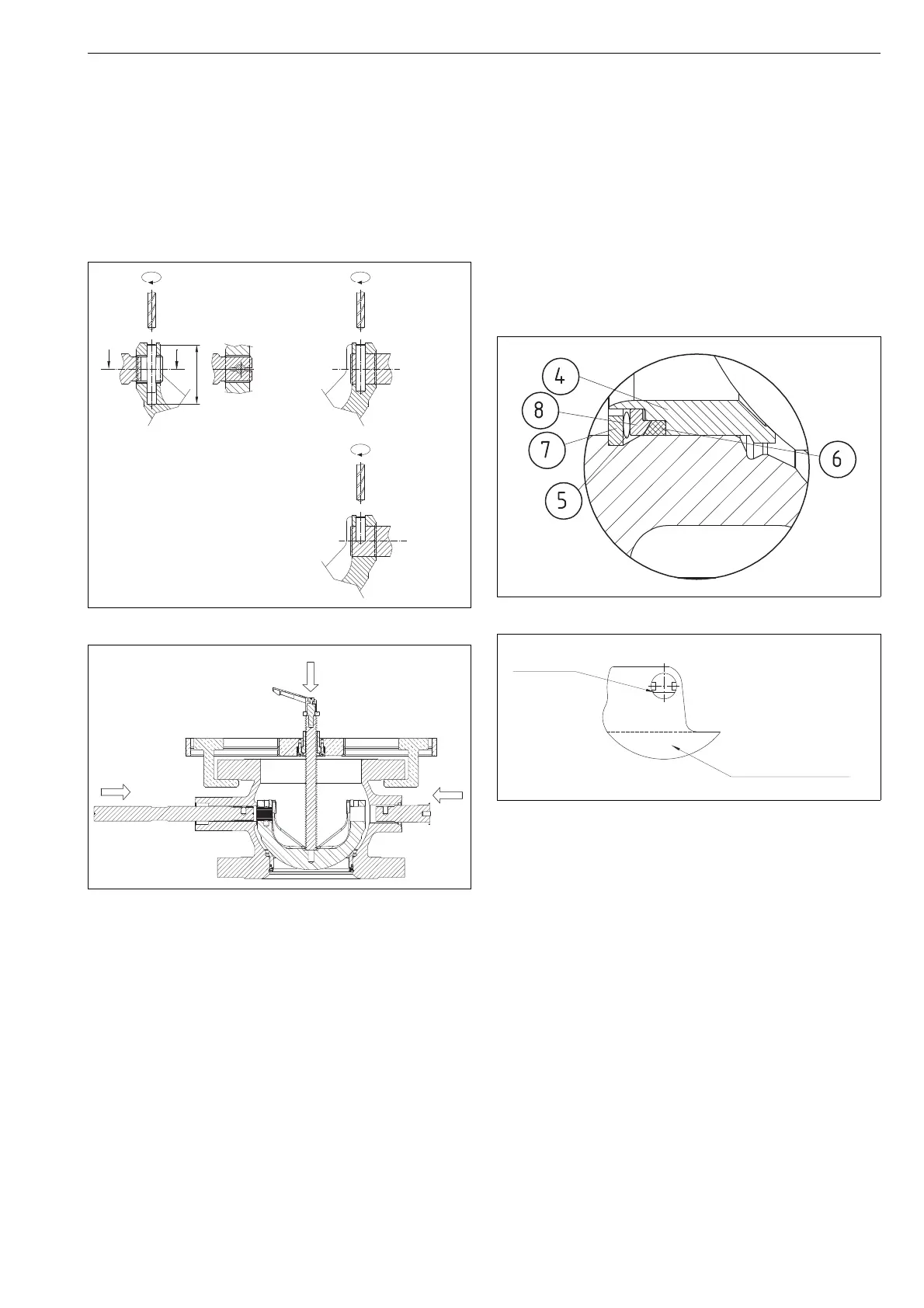

Remove the shafts (11 and 12), Fig. 33.

Lift the segment from the body.

Remove the bearings (16 and 17) and clean the bear-

ing spaces.

Remove the seat by pushing it evenly inside the

body.

4.7 Inspection of removed parts

Clean the removed parts.

See if the shafts (11, 12) and bearings (16, 17) are

damaged.

Check if the sealing surfaces of the segment and the

seat (4) are damaged.

If necessary, replace the parts with new.

4.8 Assembly

The bearing material of the standard construction

valves is PTFE-impregnated stainless steel net. The

bearings for the high temperature valves are cobalt

alloy bushings which are mounted into the body

together with the shafts. High temperature is over

+260 °C.

Put the bearings (16, 17) in their places.

Mount the S, U or T-seat as explained in 4.5.2.

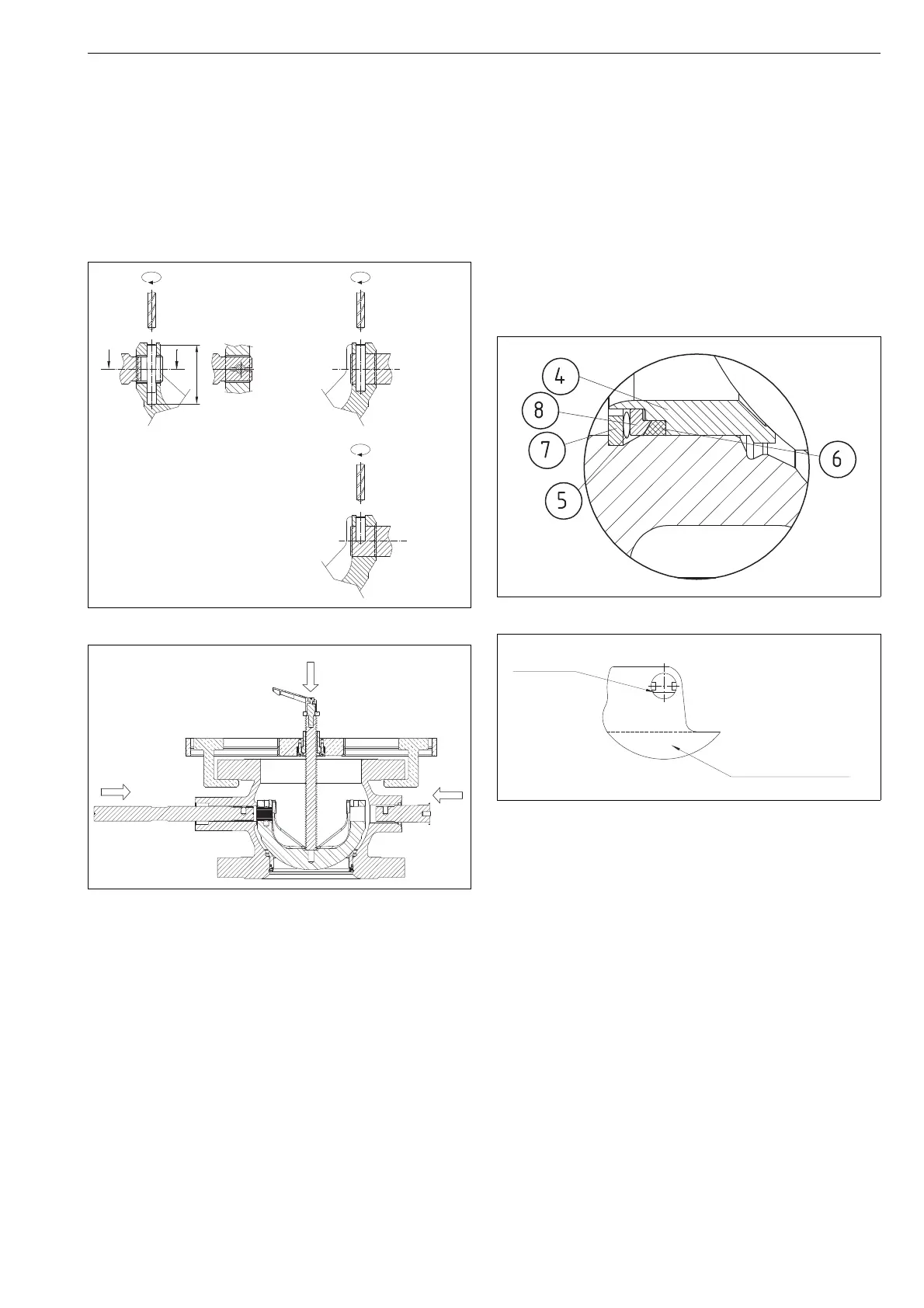

For A-seat (Fig. 34), mount the retaining ring (7) to

the groove in Body (1). Install back seal (6), support

ring (8) and spring (5) to the seat (7). Mount the

assembled seat package to the body. Use a plastic

spindle to ensure that the seat is correctly placed.

Mount the segment in the body in the closed posi-

tion. In the low Cv version, insert the filling ring (22)

between the drive shaft (11) and segment (3). Press

the segment to fit the shaft (12).

For A-seat special compression tool is needed for

compress the spring to mount the shaft and drive

shaft. See Fig. 33.

Install the drive shaft (11). Note the location of the

pin hole and the keyway. See Figs. 36 and 37.

High temperature-construction: Mount the bear-

ings (16, 17 and 18) into the shafts. Spray a thin layer

of dry lubricating fluid, e.g. Molykote 321R or equiva-

lent, into the inside surface of the bushing and the

shaft bearing groove. Press the bushing with a tight-

ening ring into the shaft bearing groove and fit the

shaft with the bearings carefully into the body

through the tightening ring.

Please note the depth of the hole (L) for the conical

pin, Fig. 32. Use a former to check the proper shaft

position of low Cv valves, see Fig. 36 . Put the pins

(14, 15) in their places and lock them, Fig. 37. Both

pins are locked with TIG welding in the high-consist-

ency acid-resistant version and in the standard and

high-consistency titanium versions. Moreover, the

drive shaft is welded to the segment in the high-con-

sistency versions. Contact the manufacturer for more

information.

Fig. 32 Drilling the pin

Fig. 33 Installing the shafts

Conical pin

part no. 15

DN 25...500

A - A

A

Cylindrical pin

part no. 14

DN 25...40

Cylindrical pin

part no. 14

DN 50...500

DN DRILL ø (mm) L (mm)

25, 40 2,0 18

50, 65 3,5 25

80, 100 4,2 33

150 5,0 43

200 7,0 52

250, 300 8,8 60

350, 400 12,0 90

500 16,0 120

L

Fig. 34 A-seat

Fig. 35 Segment and shaft positions

Spherical surface

marker line

Loading...

Loading...