3 R 74 en 9

4.5 Replacing the seat

S- or U-seat (not DN25-50) can be changed as described in

4.5.1 & 4.5.2. For DN25-50 and other seats, the valve needs

to be dismantled as described in 4.6

4.5.1 Detaching the S- or U-seat

The valve must be removed from the pipeline.

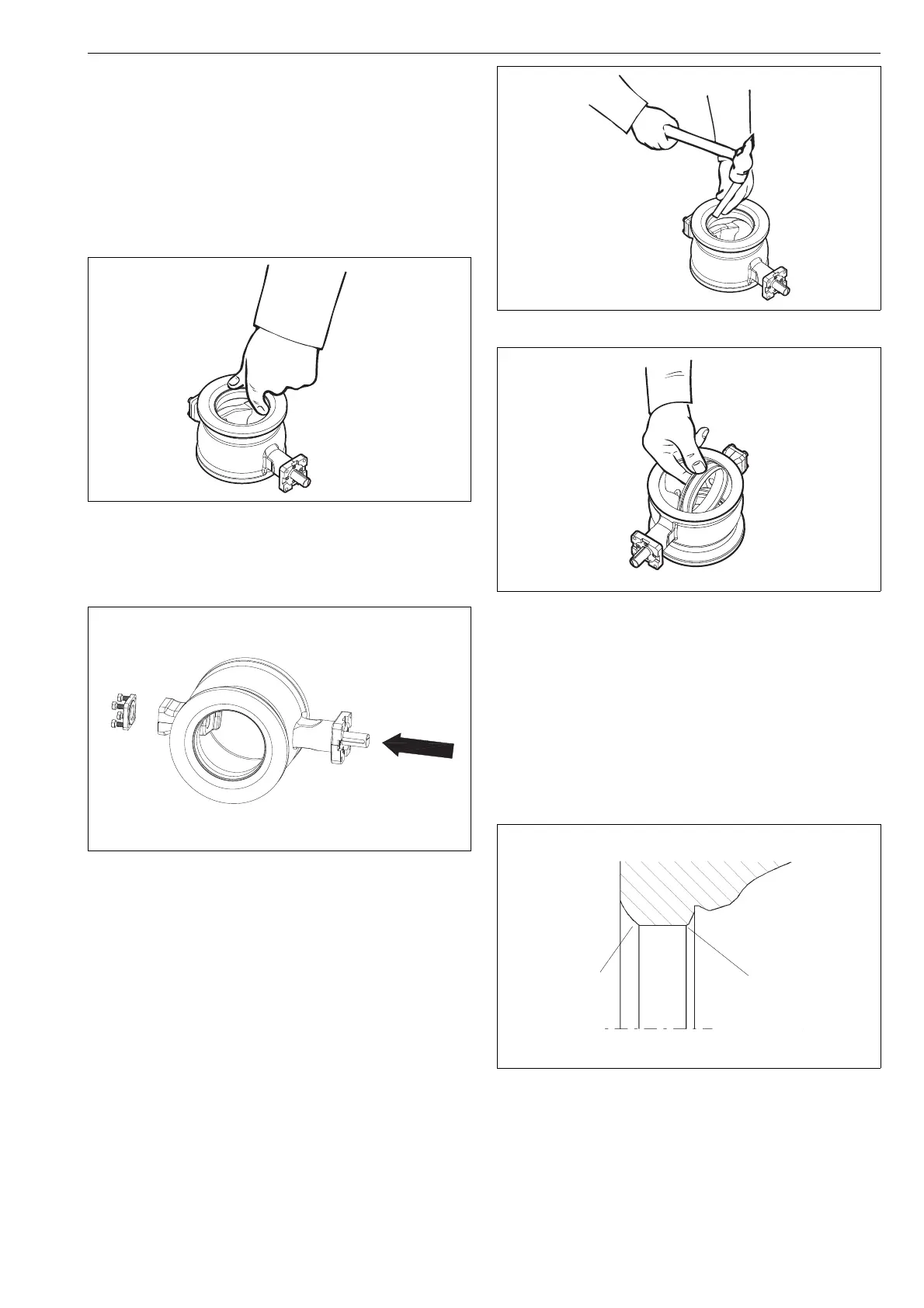

Turn the segment (3) so that it does not touch the

seat, Fig. 20.

In DN 65-100 valves (excluding the low-Cv versions),

unfasten the blind flange (10) and push the segment

into the back position, Fig. 21.

DN 65-100 valves can be dismantled, as described in

4.6, to make the replacement of the seat easier.

Tap the seat (4) with a soft spindle all around the cir-

cumference from the upstream side to make it fall

into the body, Fig. 22.

Turn the valve and lift the seat from the body

through the downstream flow port, Fig. 23.

Clean and check the removed parts.

4.5.2 Installing the seat

The back seal (6) of the segment seat (4) is normally a lip

seal. The seat is easier to install if the back seal is precom-

pressed. An O-ring seal does not need precompression.

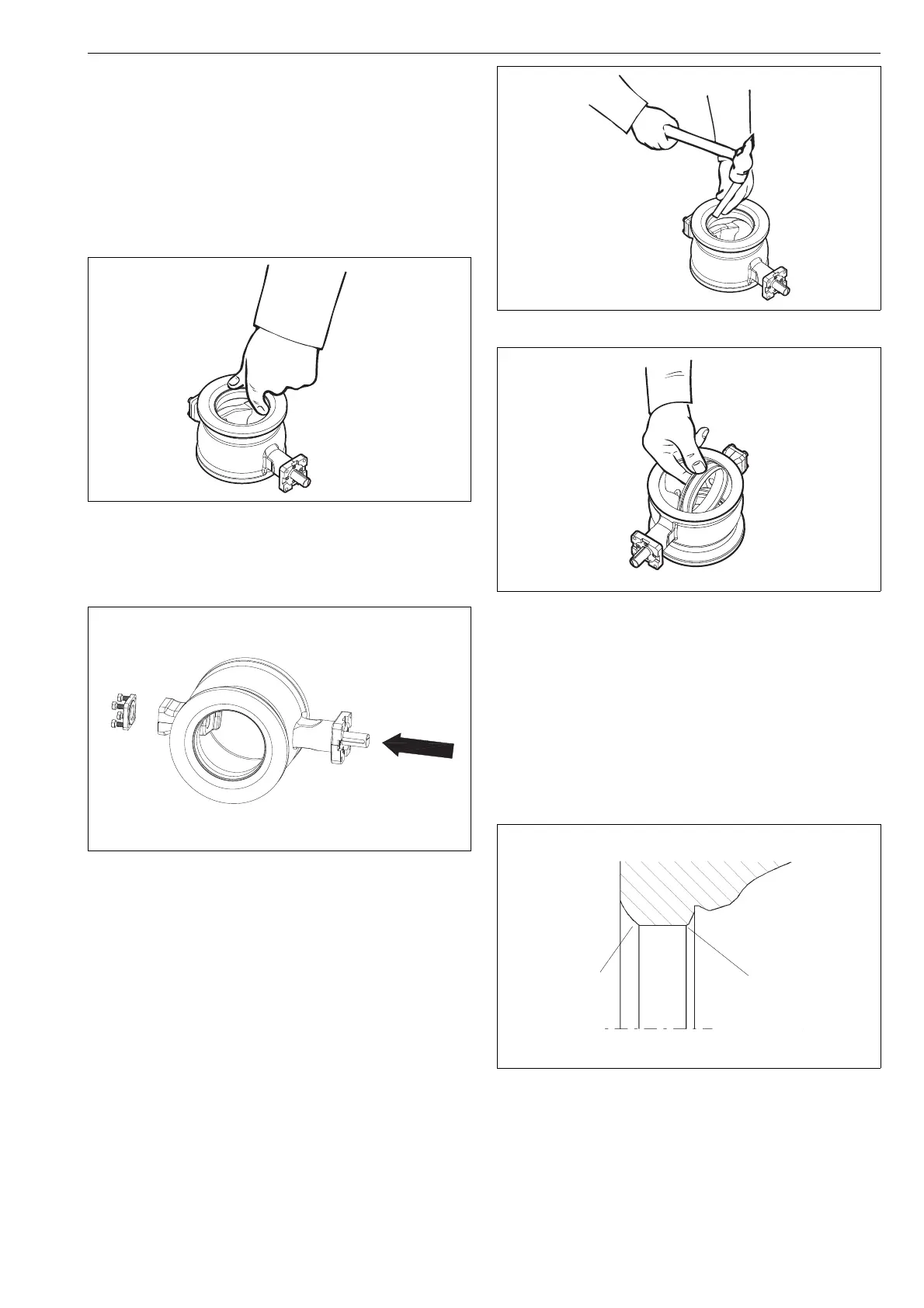

Clean the flow port that houses the seat. Remove

any burrs. Round off the edges using a fine abrasive

paper and clean the flow port carefully, see Fig. 24.

Place the back seal (6) onto the seat (4).

Lubricate the flow port, seat (4) and back seal (6) and the

lock spring (5) with a volatile lubricant, e.g. Hyprez.

Make sure that the lubricants are compatible with

the medium.

Only for a lip seal: Push the seal carefully into the

flow port for about 15 minutes, Fig. 25. The following

work phases must be completed before the precom-

pression is lost.

Place the lock spring (5) on the seat.

When the valve is opened, the ends of the spring

must be by the V-shaped opening, see Fig. 26.

Place the seat package into the body as shown in

Figs. 27 and 28.

Fig. 20 Turning the ball segment

Fig. 21 Removing the blind flange

Fig. 22 Knocking off the seat

Fig. 23 Lifting the seat

Fig. 24 Rounding the sharp edges

sharp edges

must be

rounded off

sharp edges

must be

rounded off

Loading...

Loading...