3 R 74 en 5

1.5 Valve approvals

The valve meets the Fire-safe requirements of BS6755/API

607 Edition 3.

1.6 CE marking

The valve meets the requirements of the European Direc-

tive 2014/68/EU relating to pressure equipment, and has

been marke

d according to the Directive.

1.7 Recycling and disposal

Most valve parts can be recycled if sorted according to

material. Most parts have material marking. A material list is

supplied with the valve. In addition, separate recycling and

disposal instructions are available from the manufacturer. A

valve can also be returned to the manufacturer for recycling

and disposal against a fee.

1.8 Safety precautions

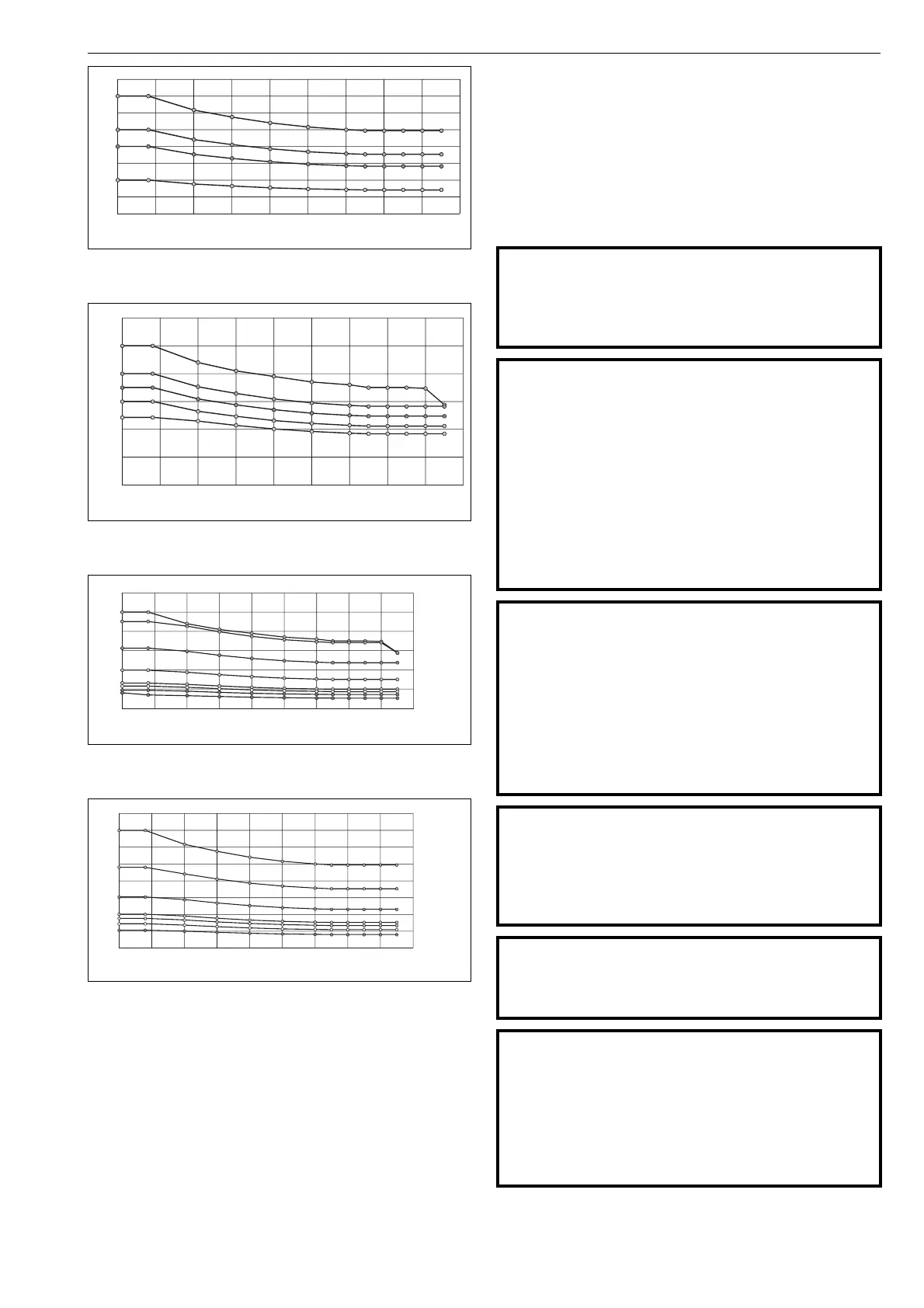

Fig. 9 Max operating pressure differential in control service,

RE opening range 70 %-100 %

Fig. 10 Max operating pressure differential in control service,

Q-RE opening range 0 %-30 %

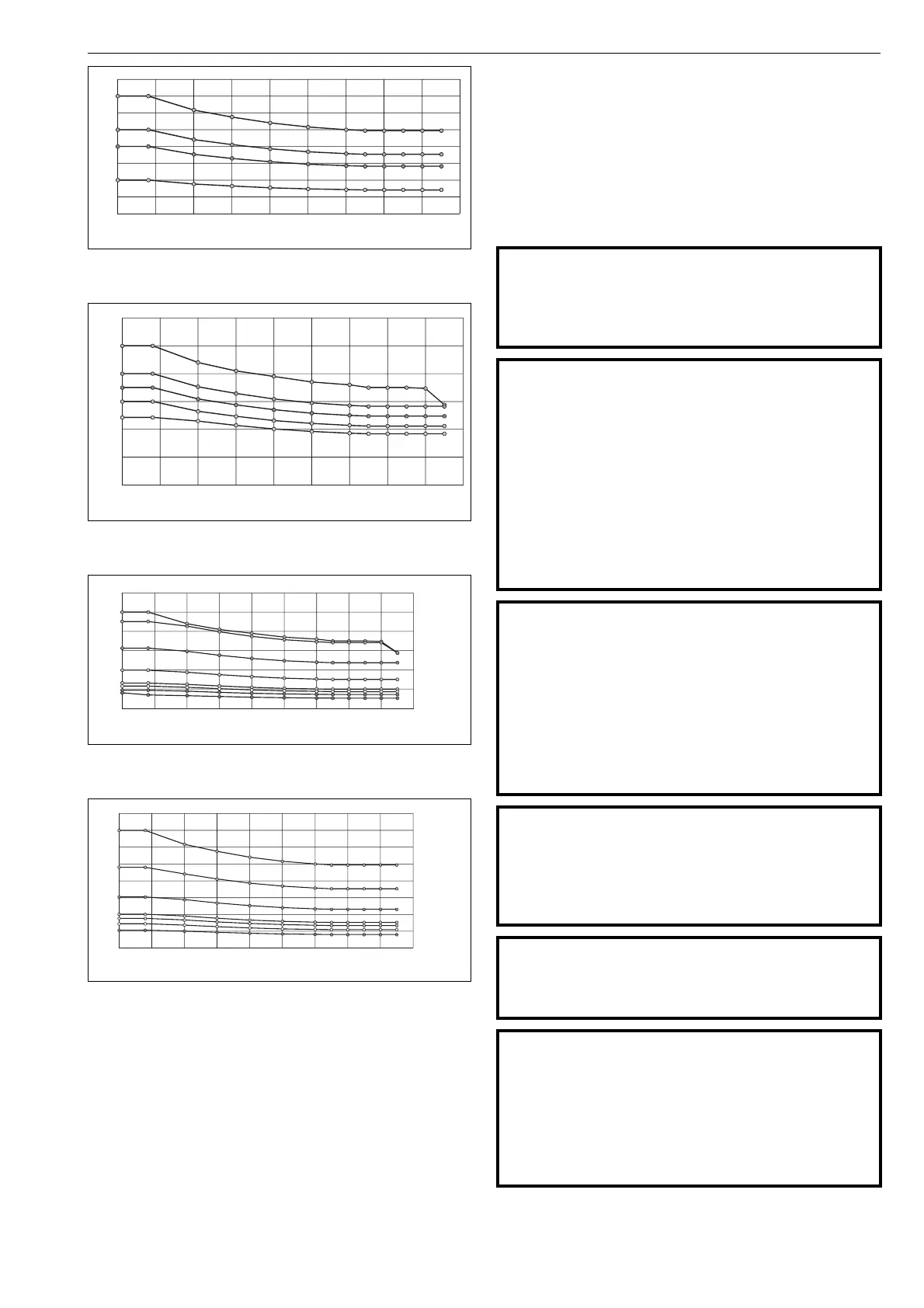

Fig. 11 Max operating pressure differential in control service,

Q-RE opening range 30 %-60 %

Fig. 12 Max operating pressure differential in control service,

Q-RE opening range 60 %-100 %

0

5

10

15

20

25

30

35

40

Pressure Bar

DN25-80/1"-3"

DN100-200/4"-8"

DN250/10"

DN300-700/12"-28"

0 50 100 150 200 250 300 350 400 450

Temperature °C

0

10

20

30

40

50

60

Pressure Bar

DN50-80/2"-3"

DN100-150/4"-6"

DN200-250/8"-10"

DN300-600/12"-24"

DN700/28"

0 50 100 150 200 250 300 350 400 450

Temperature °C

0

10

20

30

40

50

60

Pressure Bar

DN50&80/2"&3"

DN65/2,5"

DN100/4"

DN150/6"

DN200/8"

DN250/10"

DN300-600/12"-24"

DN700/28"

0 50 100 150 200 250 300 350 400 450

Temperature °C

0

5

10

15

20

25

30

35

40

Pressure Bar

DN50-80/2"-3"

DN100-4"

DN150/6"

DN200/8"

DN250/10"

DN300-600/12"-24"

DN700/28"

0 50 100 150 200 250 300 350 400 450

Temperature °C

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve may cause

damage and lead to uncontrolled pressure release. Dam-

age or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

Dismantling or removing a pressurized valve will result in

uncontrolled pressure release. Always isolate the relevant

part of the pipeline, release the pressure from the valve

and remove the medium before dismantling the valve.

Be aware of the type of medium involved. Protect yourself

and the environment from any harmful or poisonous sub-

stances. Make sure that no medium can enter the pipeline

during valve maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of the segment movement!

Keep hands, other parts of the body, tools and other

objects out of the open flow port. Leave no foreign

objects inside the pipeline. When the valve is actuated,

the segment functions as a cutting device. The segment

position may also change when the valve is moved. Close

and detach the actuator pressure supply pipeline for valve

maintenance. Failure to do this may result in damage or

personal injury.

CAUTION:

Protect yourself from noise!

The valve may produce noise in the pipeline. The noise

level depends on the application. It can be measured or

calculated using the Metso Nelprof software. Observe the

relevant work environment regulations on noise emission.

CAUTION:

Beware of a very cold or hot valve!

The valve body may be very cold or very hot during use.

Protect yourself against cold injuries or burns.

CAUTION:

When handling the valve or the valve package, take its

weight into account!

Never lift the valve or valve package by the actuator, posi-

tioner, limit switch or their piping.

Place the lifting ropes securely around the valve body (see

Fig. 13). Damage or personal injury may result from falling

parts.

Loading...

Loading...