3 R 74 en 7

The actuator must not touch the pipeline, because pipeline

vibration may damage it or interfere with its operation.

In some cases, for instance when a large-size actuator is

used or when the pipeline vibrates heavily, supporting the

actuator is recommended. Contact Metso Flow Control

business for further information.

3.4 Commissioning

Ensure that no dirt or foreign objects are left inside the

valve or pipeline. Flush the pipeline carefully. Keep the

valve entirely open during flushing.

Check all joints, pipings and cables.

Check that the actuator, positioner and limit switches are

correctly adjusted. Refer to their installation, operation and

service manuals.

4 MAINTENANCE

4.1 Maintenance general

Although Metso’s Neles valves are designed to work under

severe conditions, proper preventative maintenance can

significantly help to prevent unplanned downtime and in

real terms reduce the total cost of ownership. Metso recom-

mends inspecting the valves at least every five (5) years.

The inspection and maintenance interval depends on the

actual application and process condition.

The inspection and maintenance intervals can be specified

together with your local Metso experts. During this periodic

inspection the parts detailed in the Spare Part Set should

be replaced.

Time in storage should be included in the inspection inter-

val.

Maintenance can be performed as presented below. For

maintenance assistance, please contact your local Metso

office. The part numbers in the text refer to the exploded

view and to the parts list in Section 10, unless otherwise

stated.

4.2 Replacing the gland packing

4.2.1 RA series

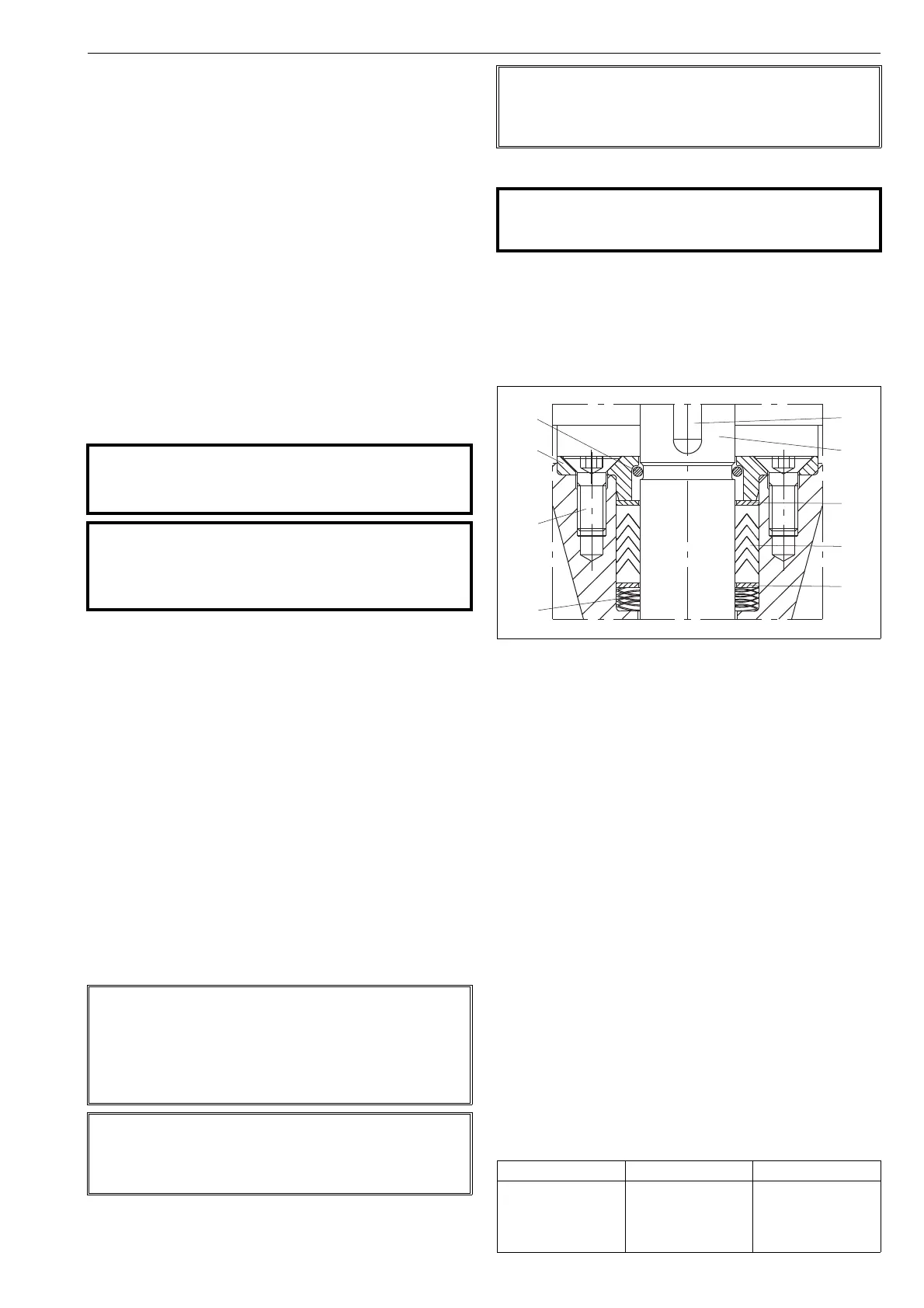

In gland packing, V-ring set (20), tightness is ensured by

pressure caused by the wave spring (32). See Fig. 17.

The gland packing must be replaced when leakage occurs

through the gland (9).

Make sure the valve is not pressurized.

Remove the actuator from the valve shaft acc. to the

instructions given in the actuator’s manual.

Remove the key (13) from the drive shaft (11). Unfas-

ten the screws (25) and the gland (9).

Remove the retainer (30) from the drive shaft. Avoid

to damage the shaft’s surface.

Remove the upper sheet ring (31).

Remove the old packing rings (20) using a pointed

pin. Avoid to damage the sealing surfaces.

Remove the lower sheet ring (31) and the wave

spring (32).

Clean the packing ring counterbore.

Mount the spring (32) and the lower sheet ring (31)

into the counterbore.

Mount the new packing rings (20) one by one on the

shaft (11) using the gland (9) as a tool. The keyway

and shoulder must not damage the packing rings.

Mount the upper sheet spring (31).

Mount the retainer (30) in the groove of the shaft.

Avoid to damage the surface of the shaft.

Fasten the gland (9) with the screws (25) and tighten

them according to the Table 2.

Mount the key (13) on the shaft (11).

CAUTION:

Observe the safety precautions mentioned in Section

1.8 before maintenance!

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package.

NOTE:

When sending goods to the manufacturer for repair, do

not disassemble them. Clean the valve carefully and flush

the valve internals. For safety reasons, inform the manu-

facturer of the type of medium used in the valve (include

material safety datasheets (MSDS)).

NOTE:

In order to ensure safe and effective operation, always use

original spare parts to make sure that the valve functions

as intended.

NOTE:

For safety reasons, replace pressure retaining bolting if the

threads are damaged, have been heated, stretched or cor-

roded.

CAUTION:

Do not dismantle the valve or remove it from the pipe-

line while the valve is pressurized!

Fig. 17 Gland packing

Table 1 Torques for gland screws

Thread Torque, Nm Width across flats

M6

M8

UNC 1/4

UNC 5/16

8

18

8

18

4 mm

5 mm

5/32"

3/16"

Loading...

Loading...