Easidew Online User’s Manual

Michell Instruments 41

MAINTENANCE

4.1 General Operational Guidelines

General guidelines to be followed when setting-up a sampling system are as follows:

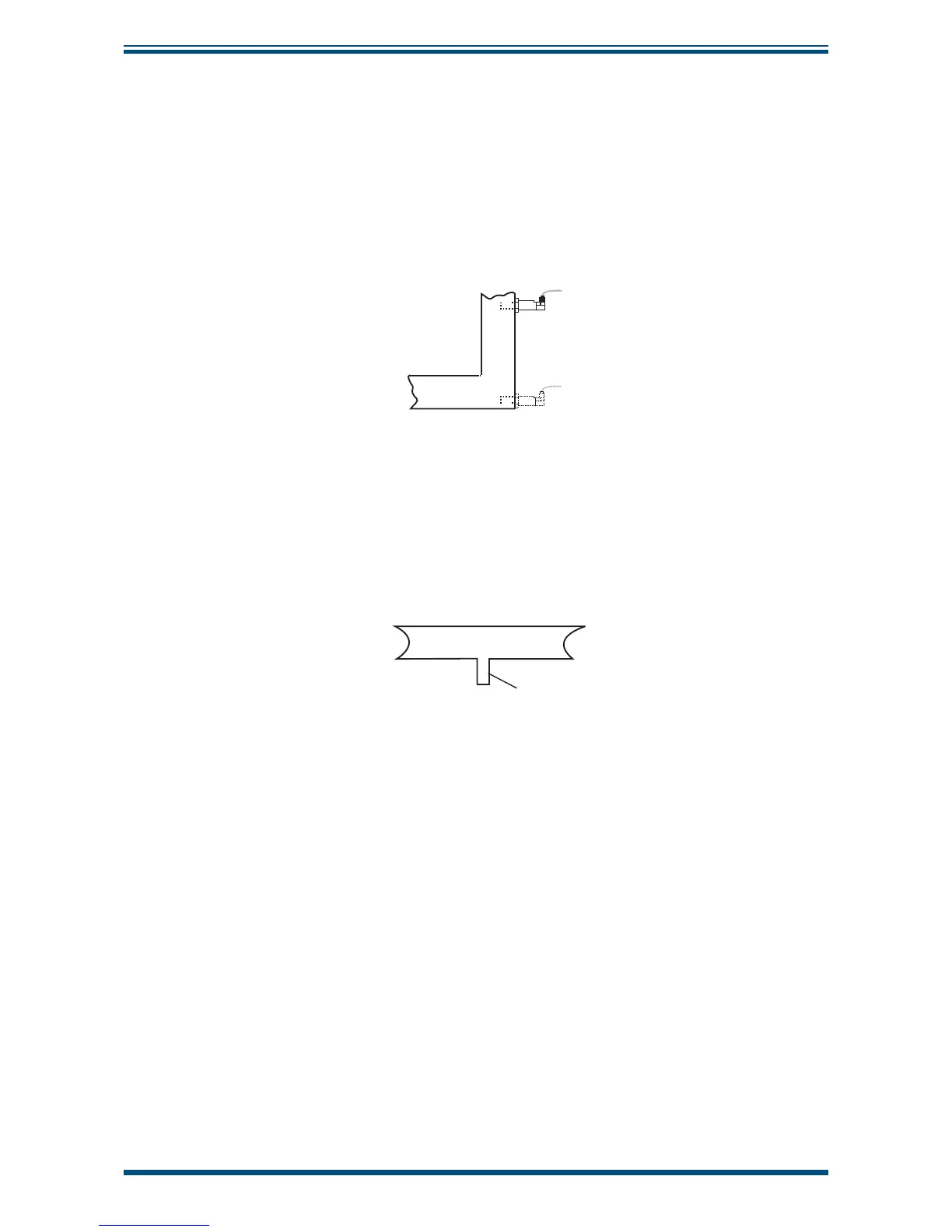

• Transmitter Positioning

The sample point should be as close to the critical measurement point as possible. Also,

never sample from the bottom of a pipe as entrained liquids may be drawn into the

sensing element.

Figure 31

Installation Location

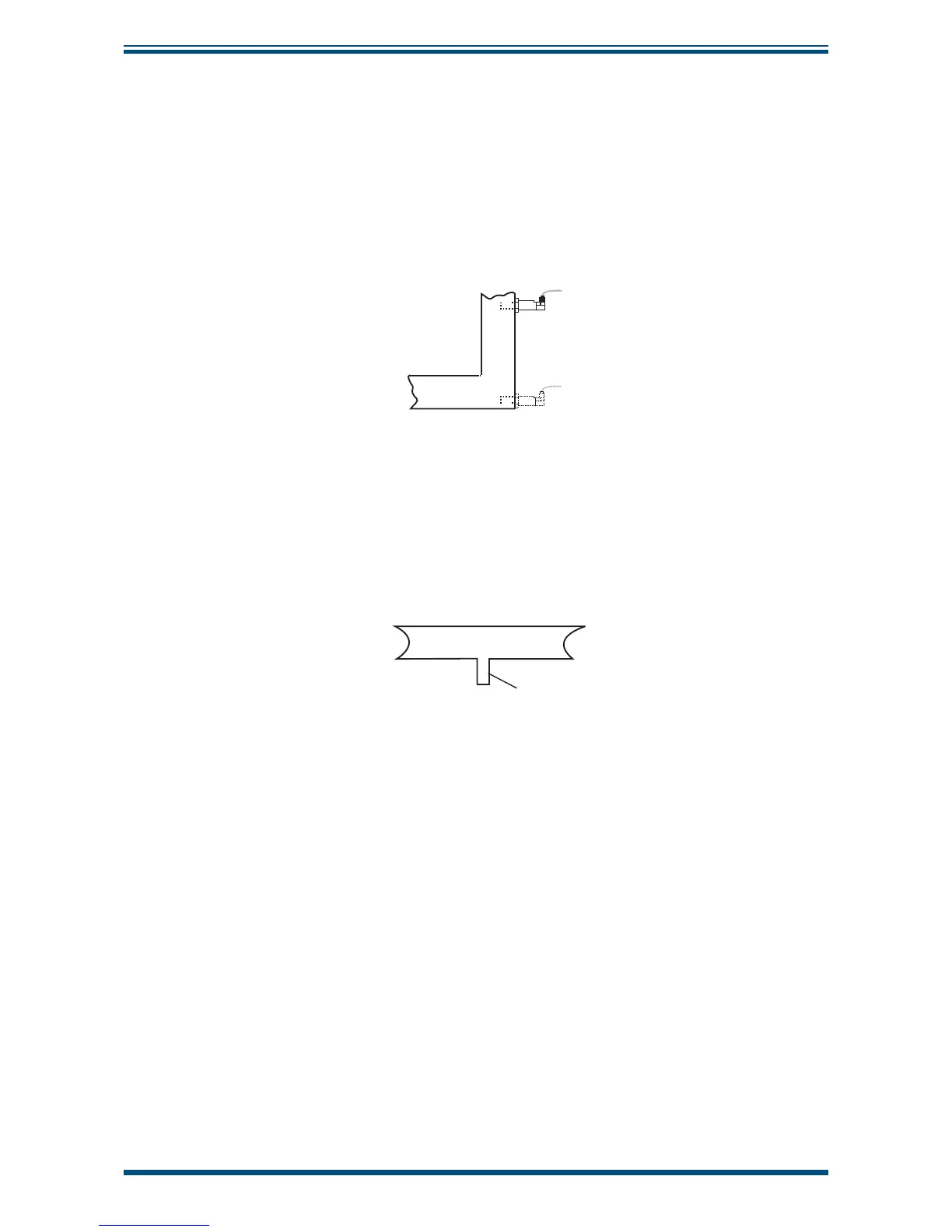

• Avoidance of Dead Spaces

Dead space causes moisture entrapment points, increased system response times and

measurement errors, as a result of the trapped moisture being released into the passing

sample gas and causing an increase in partial vapor pressure.

Deadspace

Figure 32

Indication of Dead Space

• Particulate and Oil Removal

Particulate matter at high velocity can damage the sensing element and similarly, at

low velocity, they may ‘blind’ the sensing element and reduce its response speed. If

particulate, such as degraded desiccant, pipe scale or rust is present in the sample gas,

use an in-line fi lter.

• High Quality Tube and Fittings

Michell Instruments recommends that, wherever possible, stainless steel tubing and

fi ttings should be used. This is particularly important at low dew points since other

materials have hygroscopic characteristics and adsorb moisture on the tube walls,

slowing down response and, in extreme circumstances, giving false readings. For

temporary applications, or where stainless steel tubing is not practical, use high quality

thick walled PTFE tubing.

Loading...

Loading...