Easidew PRO XP User’s Manual

8 97442 Issue 5, May 2018

INSTALLATION

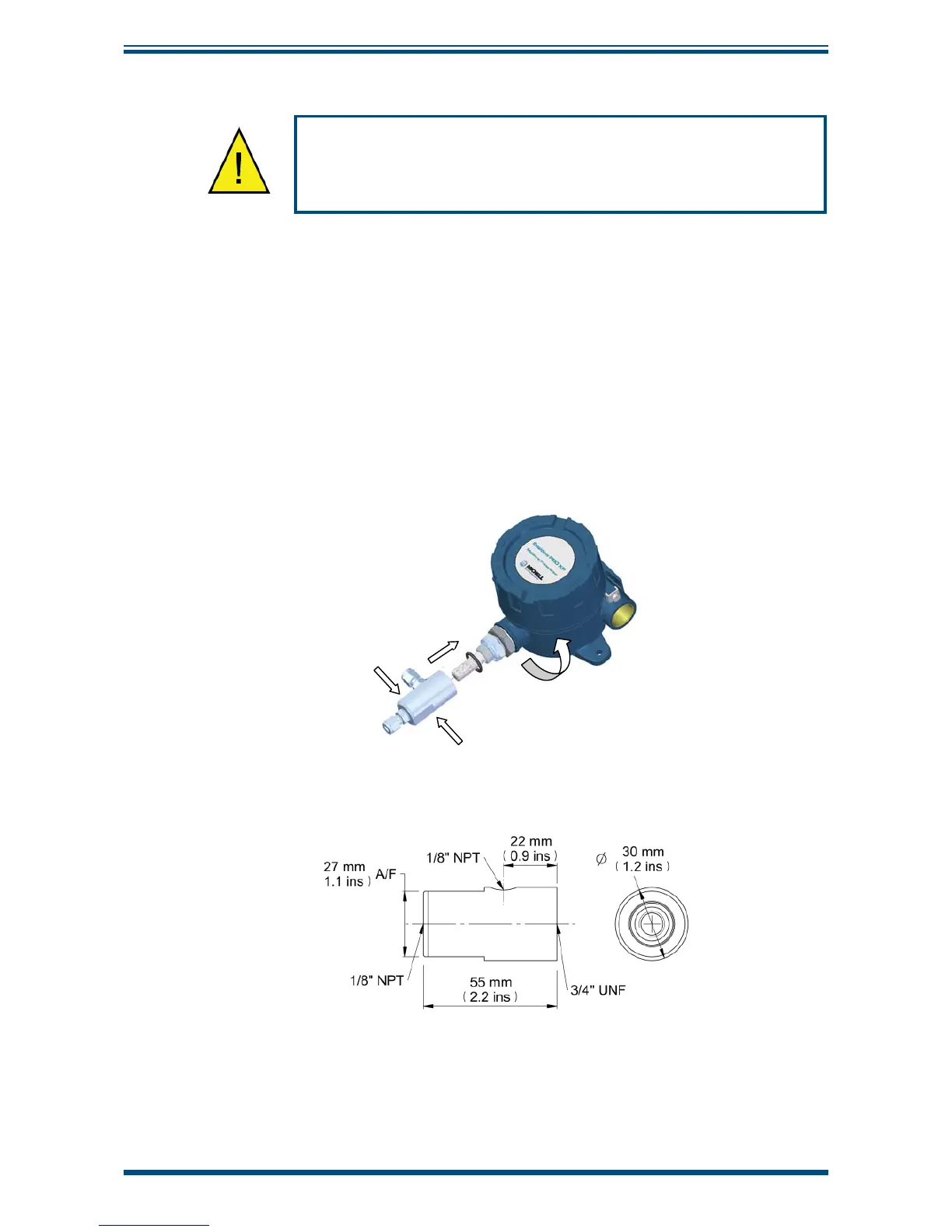

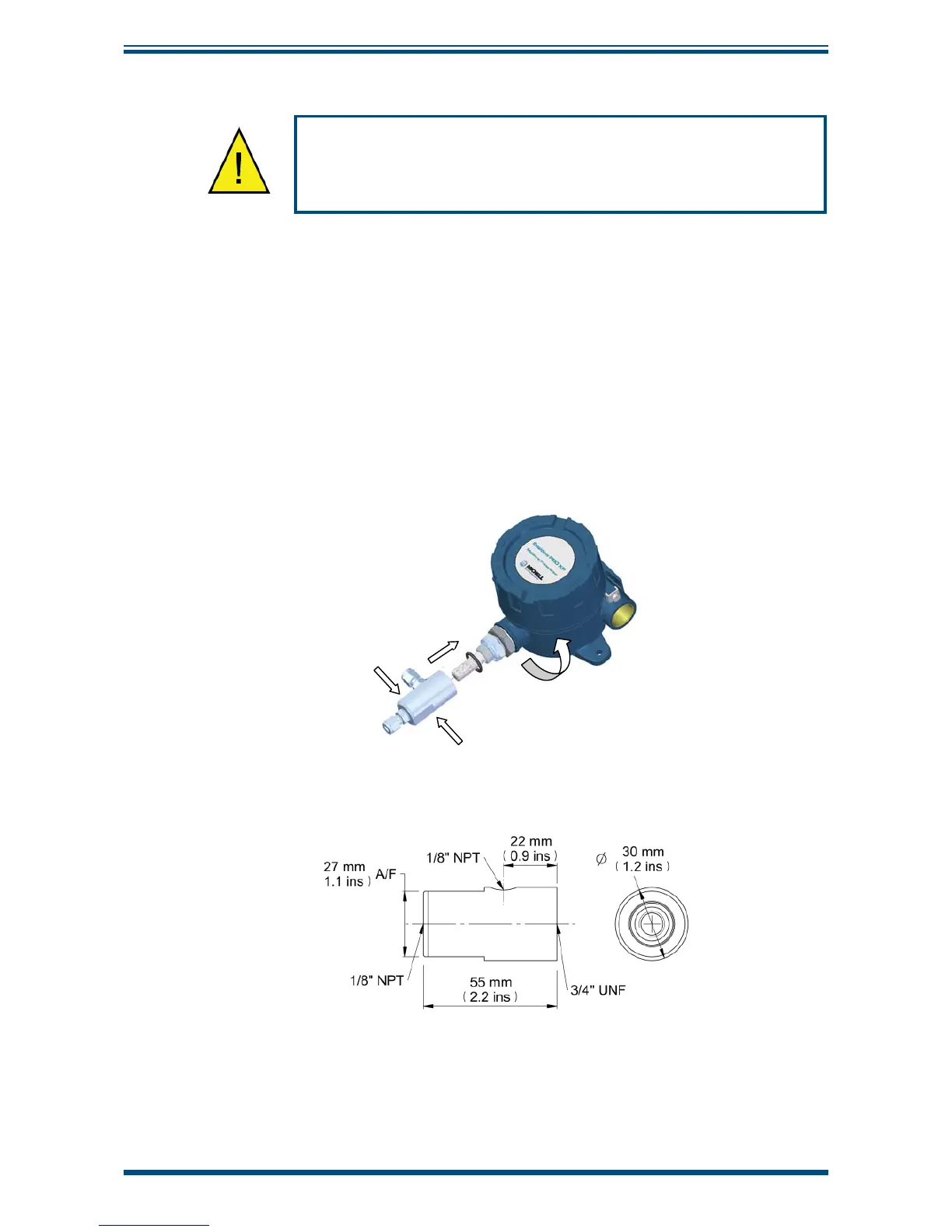

2.3.1 Sample Block (Optional)

The following procedure must be carried out by a qualifi ed

engineer to ensure the safe operation of the pressure system.

1. Remove the green protective cap and desiccant capsule.

2. Ensure the O-ring (see

Figure 8)

is located correctly within the O-ring

groove of the process connection and there is no contamination or debris

on its exposed surfaces.

3. Screw the transmitter into the sample block and, whilst holding the fl ats

on the block, tighten the seal nut to 40Nm (29.5 lbf-ft) to compress the

O-ring.

4. Rotate the enclosure to the desired position (up to 360° available) and

tighten the large clamping nut (32mm 1¼”) to 10Nm (7.4 lbf-ft) to ensure

dowty seal is correctly compressed for environmental protection (see

Appendix B.1).

Loading...

Loading...