The power to the enclosure must be turned off before any

work is carried out in the measurement system enclosure.

Observe de-energize durations.

Gas line connections to the measurement system must be

isolated and de-pressurized before any work commences.

4.1 Calibration

Routine maintenance of the Easidew PRO XP is confi ned to regular re-calibration by

exposure of the transmitter to sample gases of known moisture content to ensure that

the stated accuracy is maintained. Calibration services traceable to the UK

National

Physical Laboratory

(NPL) and the US

National Institute of Standards and Technology

(NIST) are provided by Michell Instruments.

Michell Instruments offers a re-calibration service to suit specifi c needs. A Michell

representative can provide detailed, custom advice (for Michell Instruments’ contact

information go to www.michell.com).

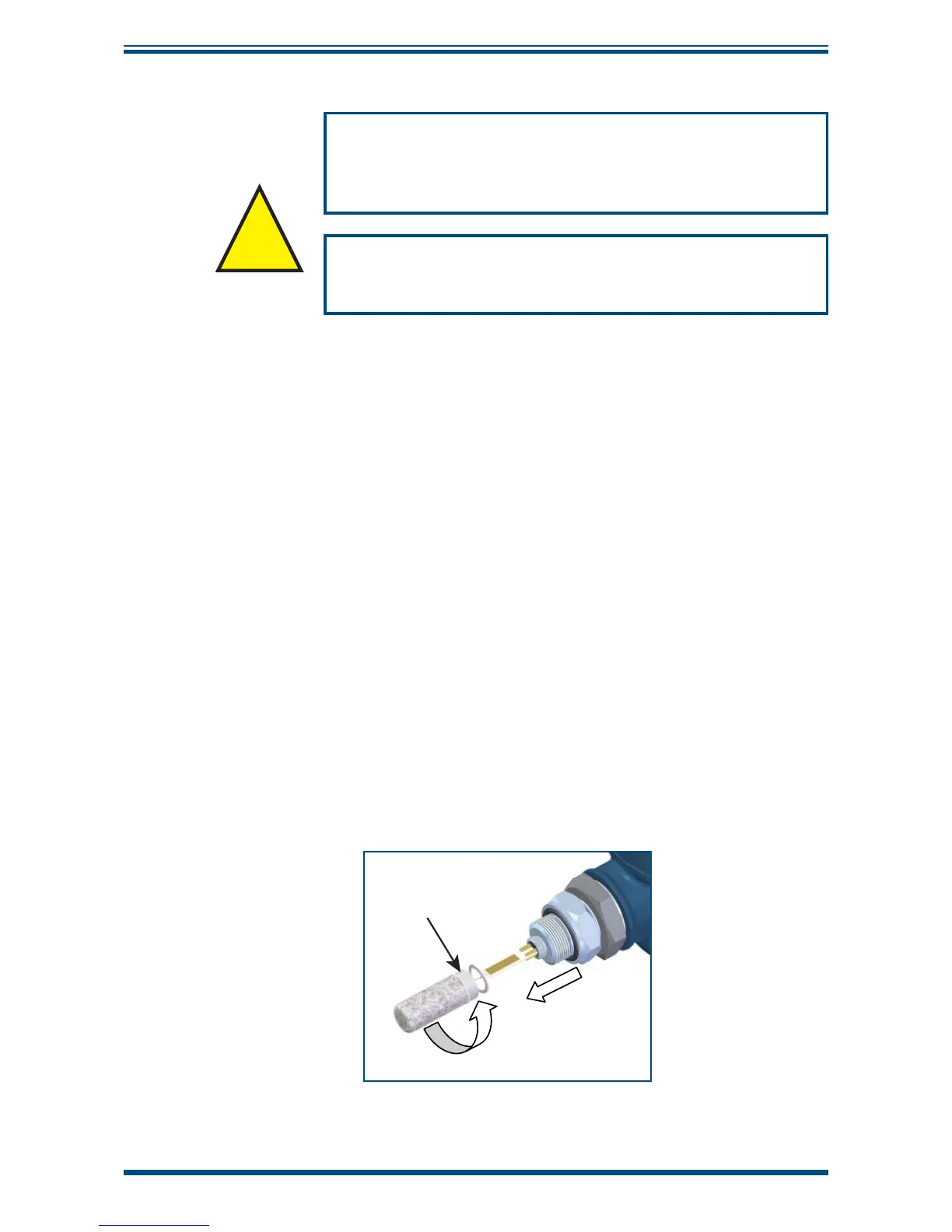

4.2 Sensor Guard Replacement

The sensor is supplied with either a stainless steel sintered or HDPE guard.

The stainless steel guard provides >80m protection to the dew-point sensor, whereas

the HDPE protects to >10m. It is designed to show any contamination and the guard

should be changed if the surface becomes discolored.

When replacing the guard, care should be taken to minimize touching the guard which

should be handled by the threaded part. Replacement guards can be obtained by

contacting Michell Instruments (www.michell.com) or your local distributor.

Please note the sensor tile should not be touched.

Loading...

Loading...