OM-263 657 Page 29

6-2. Welding Power Source And Remote Interface Operation Description

Power Switch Use this switch to power up or power down the welding power source.

. The fan is thermostatically controlled and only runs when cooling is needed.

AMPS Display This display illuminates and shows amperage for either TIG or stick welding process. Measured amperage just

prior to the end of a welding operation will appear on the display for ten seconds after welding operation.

TIG Process Select Button Press and release this button to activate the TIG welding process controls. The TIG text below the button

illuminates. Adjust the amperage to the appropriate setting within a range from 10 to 350 amps. If the TIG

process has been selected and a remote current/contactor control is connected, holding the TIG process select

button for more than two seconds will display the effective amperage command (based on the amperage setting

and the remote current/contactor control setting).

Stick Process Select

Button

Press and release this button to activate the stick welding process controls. The STICK text below the button

illuminates as well as the active stick electrode type text. Select the desired stick electrode type and adjust the

amperage to the appropriate setting within a range from 40 to 350 amps.

Stick Electrode Type

Select Button

Press and release button to select the desired stick electrode type (EXX10 or EXX18). The text above or below

the button will illuminate for the active electrode type. This button is only active with the stick welding process

and only then will text for the electrode type illuminate.

. There may be a “clunk” sound from the power source when switching between Stick and TIG

processes. This is part of normal power source operation.

Adjustable DIG and

Hotstart

Press and hold the STICK button for a few seconds to enter adjustable DIG. The right decimal point will

illuminate on the display to indicate DIG. Once in adjustable DIG, press and release the STICK button again

to enter adjustable Hotstart. The middle decimal point will illuminate on the display to indicate Hotstart.

Pressing and releasing the STICK button a third time will exit the menu. The menu will automatically exit

after 10 seconds of inactivity. Pressing and releasing any button other than the STICK button while in the

menu will also exit the menu.

Amperage Adjustment

Buttons

Use these buttons to set the desired amperage setting for either TIG or stick welding process.

14-Pin Remote Connected

Indicator

The 14-PIN REMOTE text will illuminate when there is a 14-pin accessory connected to the Remote 14

receptacle on the power source.

FieldPro ACCESSORY

Connected Indicator

The FieldPro ACCESSORY text will illuminate when there is a FieldPro accessory connected to and properly

communicating with the power source.

IN USE Button Press and release this button on the power source or FieldPro Remote to illuminate the IN USE text. Press and

release again to turn IN USE text off. This lets others know that the machine is being used.

IN USE Indicator Light automatically turns on when arc is struck. Toggle light using the IN USE button during use. Light will auto-

matically turn off after four hours of inactivity.

CHECK POLARITY

Indicator

The CHECK POLARITY text will illuminate along with an error message (Err) if the work and electrode leads are

reversed. This will light only if a FieldPro accessory is connected. Power down and correct the connections (see

Section 5 for proper connections).

STICK NEGATIVE

Indicator

The DCEN (−) STICK NEG text will illuminate if the polarity is negative while in STICK mode. To activate DCEN

mode, press the STICK button and down arrow at the same time. Press the STICK button to exit this mode. The

DCEN mode can be used for EXX10 and/or EXX18 process setting. The mode has to be set for each electrode

process individually.

NOTICE − Controls on the FieldPro Remote are NOT adjustable during welding. To make adjustments during welding, use the power source controls.

Adjustments can be made if using the RHC-14 remote or wireless remote.

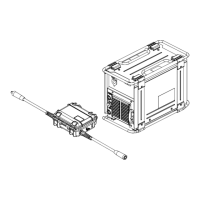

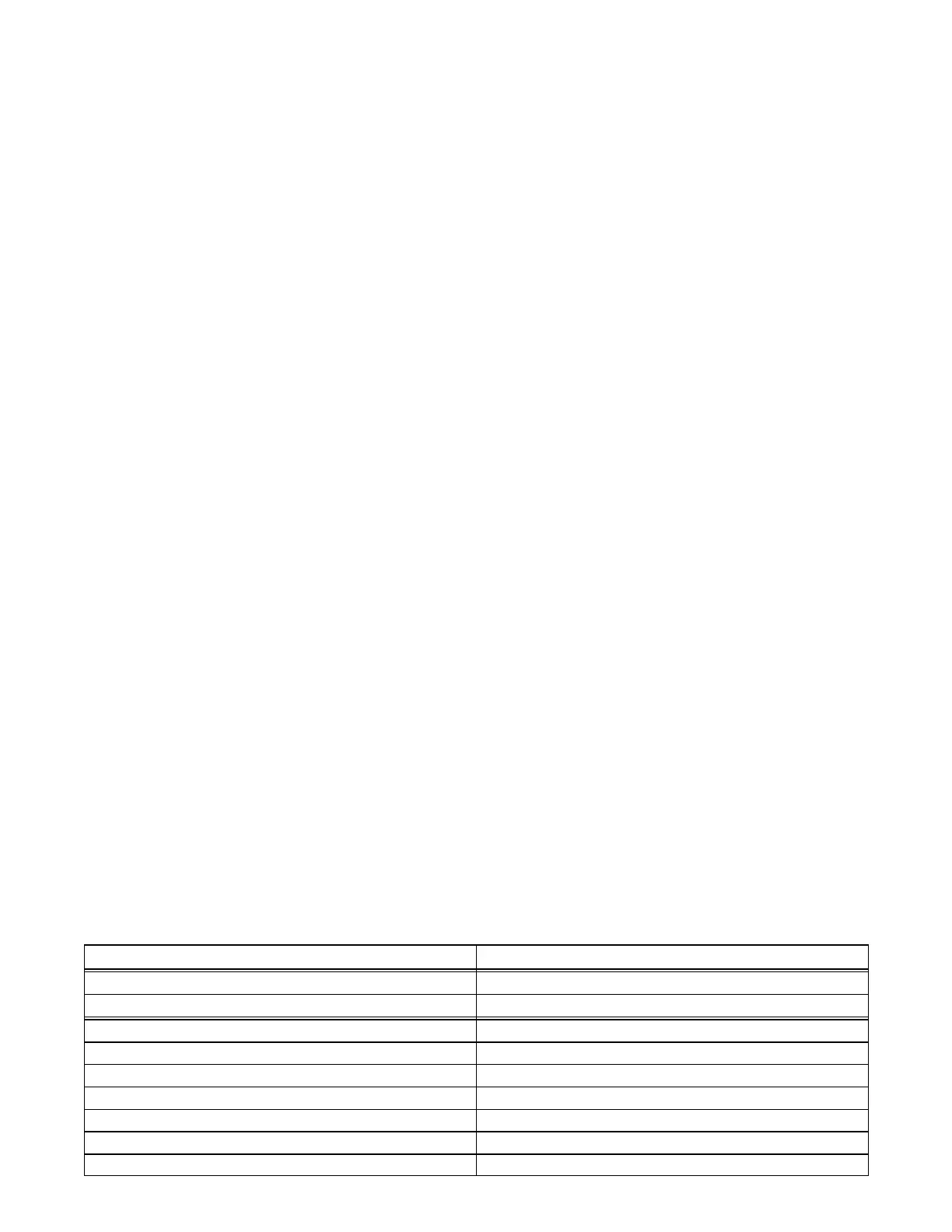

Table 6-1. Recommended Process Selections vs Electrode Type

Electrode Type Suggested Process Setting

EXXX1 EXX10

EXXX2 EXX10

EXXX3 EXX18

EXXX4 EXX18

EXXX5 EXX18

EXXX6 EXX18

EXXX7 EXX18

EXXX8 EXX18

Stainless EXX18

Loading...

Loading...