© 2009 MIMAKI ENGINEERING CO.,LTD.

1.2.4 P.1

1

2

3

4

5

6

7

8

R.1.0

Maintenance Manual > Operating Principle > Maintenance Function > PUMP TUBE WASH

Model CJV30/TPC Issued 2008.08.04 Revised F/W ver. 1.00 Remark

1.0

1.2.4 PUMP TUBE WASH

Indication on LCD

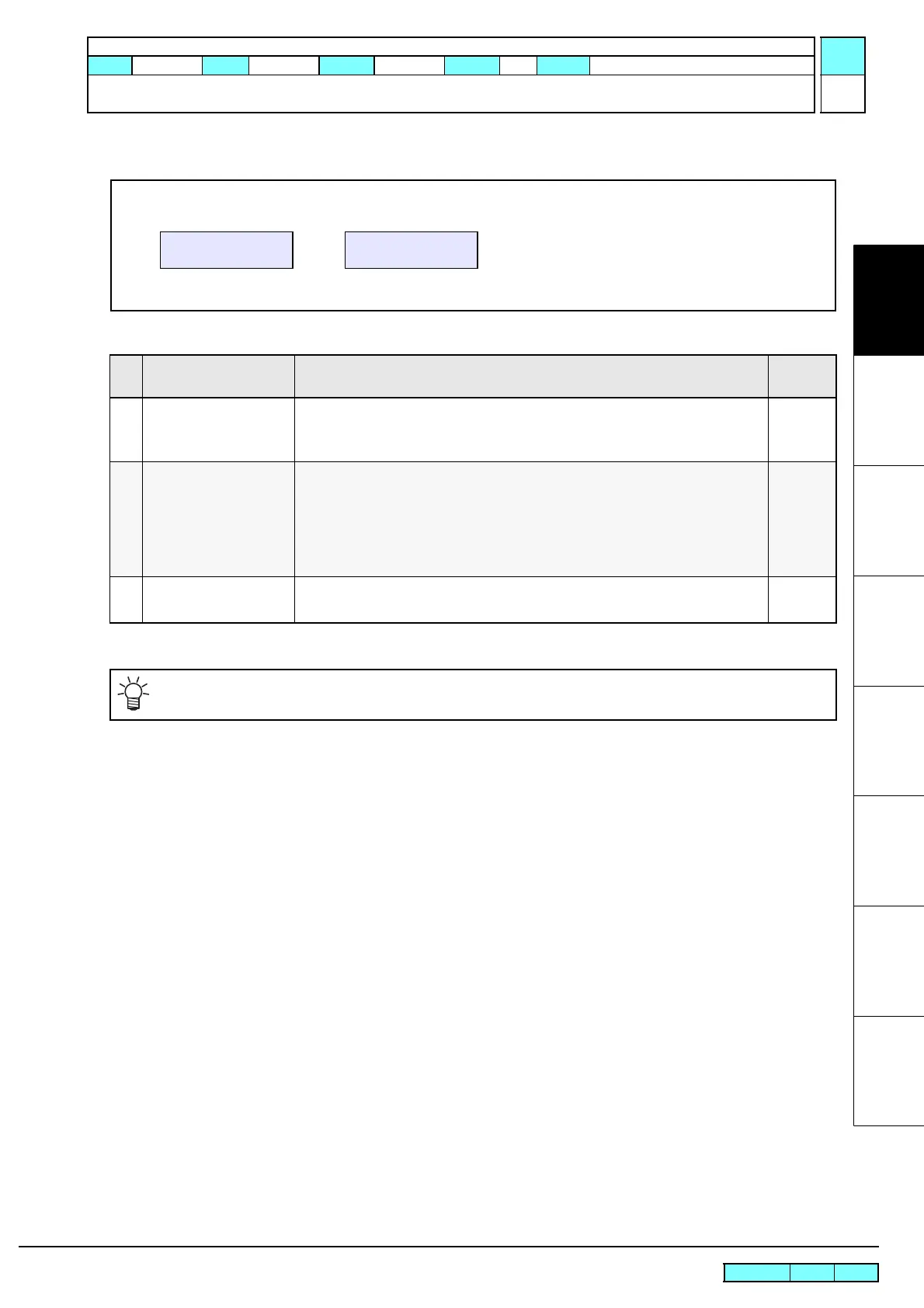

Processing sequence

Step Processing Description

Indication

on LCD

1 Start 1. Taking the cap off

2. After moving the print head carriage to the maintenance location, the wiper

moves to the wiping location and the servo motor is turned off.

2 Maintenance

(Pump tube wash)

1. Repeat the following operations until depressing [ENTER] key.

• Locking the pump tube

• No action for 10 seconds

• Dry suction for 5 seconds

2. Maintenance washing liquid is poured into the cap by depressing the

[FUNCTION] key.

3 End 1. Dry suction for 20 seconds

2. Initial Machine Operation (1.1.3)

Out of “Service mode”, a warning beep sounds at an interval of 30 seconds during carriage out operation to

prevent the nozzle surface and the inside of the cap from getting dry.

Display during maintenance

ST.MAINTENANCE

COMPLETED :ent

Display during initial operation

PLEASE WAIT

Loading...

Loading...