© 2009 MIMAKI ENGINEERING CO.,LTD.

1.3.11 P.1

1

2

3

4

5

6

7

8

R.1.0

Maintenance Manual > Operating Principle > Ink System > Initial Filling

Model CJV30/TPC Issued 2008.08.04 Revised

2010.11.05

F/W ver. 2.50 Remark

1.0

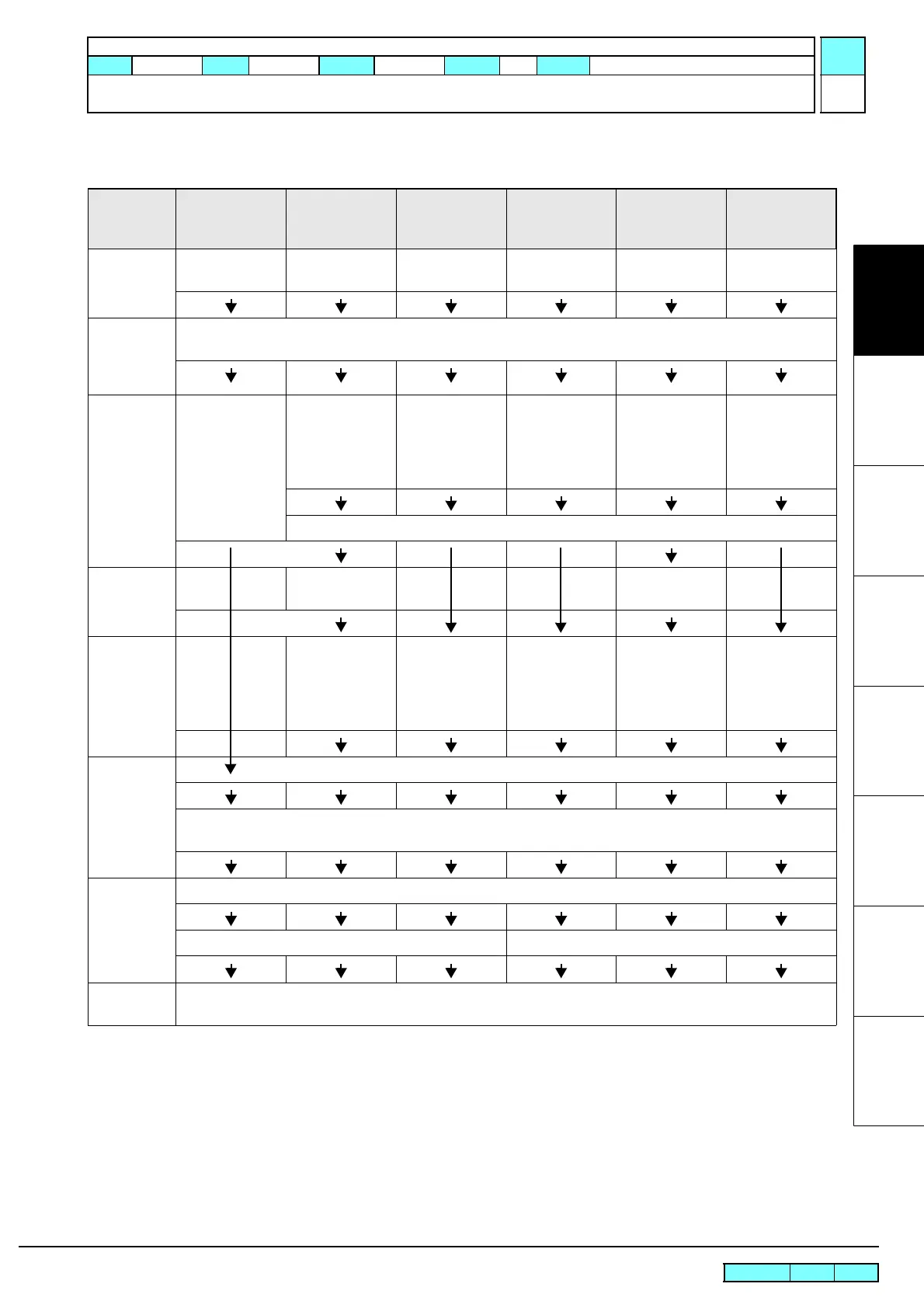

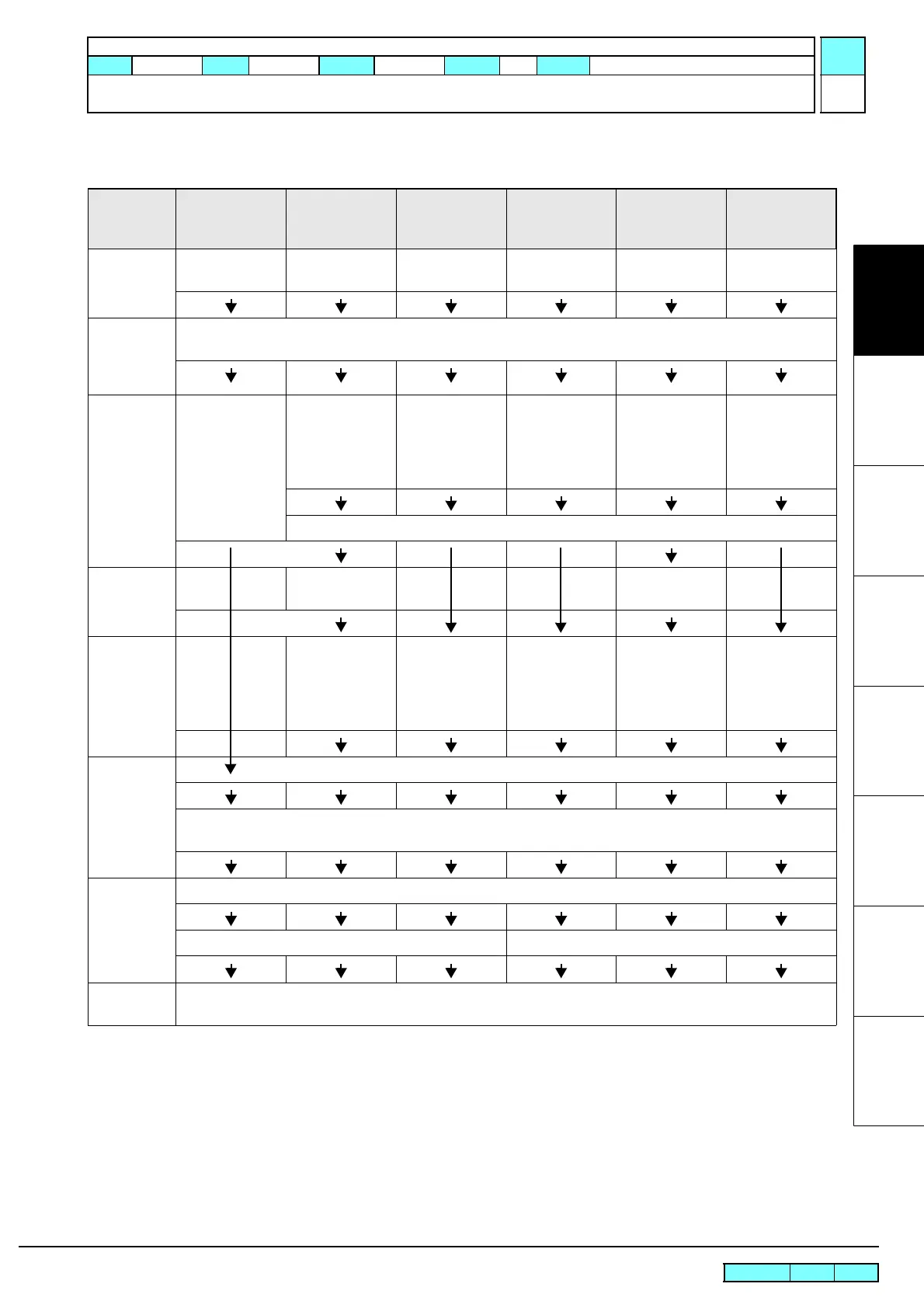

1.3.11 Initial Filling

Replacing procedure

Current ink

-> Target ink

Shipping status

ES3 8-color

SS21 4-color ->

ES3 8-color

SS21 6-color ->

ES3 8-color

SS21 6-

color+White

-> ES3 8-color

ES3 4-color ->

ES3 8-color

ES3 6-color ->

ES3 8-color

Initial status Shipping status SS21 4-color SS21 6-color SS21 6-

color+White

ES3 4-color ES3 6-color

Step1

Vers ion

check of F/W

and RLP

Check that JV33 F/W = Ver.4.60, CJV30 F/W = Ver.2.50 and RLP5 = Ver.2.2.

If they are not as above, perform version upgrade.

Step2

Head wash-

ing

Turning ON the

front power sup-

ply -> discharge

of solvent filling

liquid (SPC-

0475)

Select “YES” to

“Do you change

an ink set?” from

“#ADJUST”->

“HEAD WASH”.

Select “NO” to

“Do you change

an ink set?” from

“#ADJUST”->

“HEAD WASH”.

Select “NO” to

“Do you change

an ink set?” from

“#ADJUST”->

“HEAD WASH”.

Select “YES” to

“Do you change

an ink set?” from

“#ADJUST”->

“HEAD WASH”.

Select “NO” to

“Do you change

an ink set?” from

“#ADJUST”->

“HEAD WASH”.

MS washing liquid set -> washing

Step3

Replacing

UIS coupling

Replacing 4-color

with 8-color

Replacing 4-color

with 8-color

Step4

Replacing

damper

Replace 7th

damper only

(white is filled).

Do not replace

other than that.

Replace 7th

damper only

(white is filled).

Do not replace

other than that.

Replace 7th and

8th dampers

(white was filled).

Do not replace

other than those.

Replace 7th

damper only

(white is filled).

Do not replace

other than that.

Replace 7th

damper only

(white is filled).

Do not replace

other than that.

Step 5

Ink Filling

Select ES3 8-color for “Choose an ink type”.

ES3 8-Color

-> Filling

Step 6

Nozzle

Check

Nozzle check

Good If it is No Good, perform refilling until it becomes Good.

Step 7

Adjustment

Adjust

Loading...

Loading...