– 3.12 –

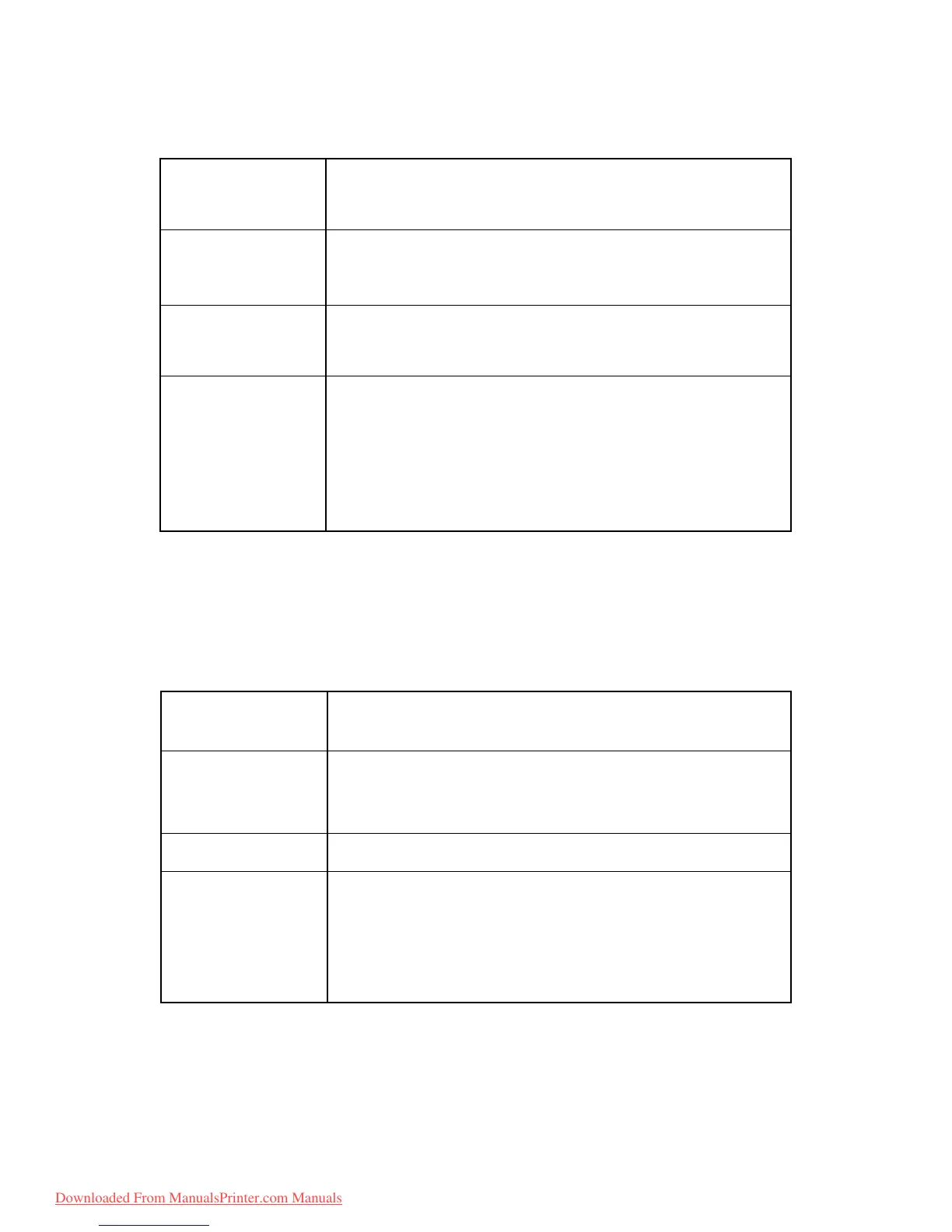

3-3-6. Abnormal nozzle discharge

Problems When checking the nozzle, the nozzle at the enter of the head does not

discharge. The head on the R side does not discharge.

The edge of the nozzle does not discharge.

Causes 1) The amount of wiper contact is large/small.

2) The wiper on the R side does not contact.

3) The capping position with respect to the head is not normal.

Checking procedure 1-2) Make visual check of the amount of wiper contact.

3) Perform the check test / the capping position.

(Refer to [6-6-2. Adjustment of the station position.])

Remedies 1) Adjust the amount of wiper contact.

2) Upglade the F/W.

(A failure may occur with F/W1.30 or earlier. )

If the wiper position on the F side is normal, the head on the R side does

not contact, and the wiper BKT is slanted, bend the wiper BKT so that

the amount of wiper contact be the same for wipers on the F and R sides.

3) Perform the adjustment of the station position.

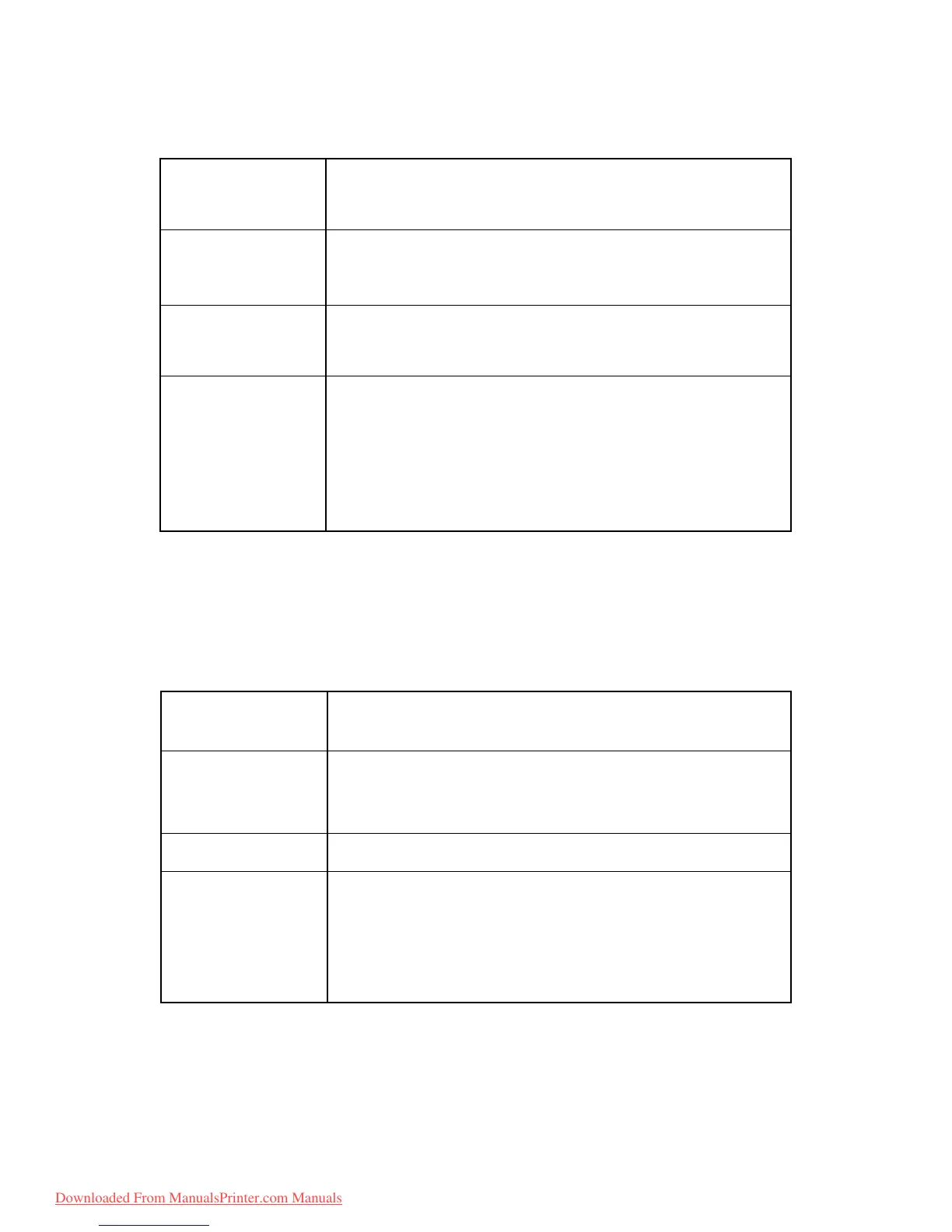

3-3-7. Board medium feeding failure

Problems Skew occurs.

The printing surface of the board makes contact with the head.

Causes 1) The amount of warp of the board is more than 1mm.

The board have an irregular sarface on the back.

2) The head height is not correct.

Checking procedure 1-2) Visually confirm the media and the head status.

Remedies 1) Use the board not having warp.

2) Adjust the height of the head.

For media with irregular surface, increase the head height.

When using a board with a length of 300mm or longer or a nonelastic

board, use a bench before or after the machine. (Refer to JV4 series

operation manual)

Downloaded From ManualsPrinter.com Manuals

Loading...

Loading...