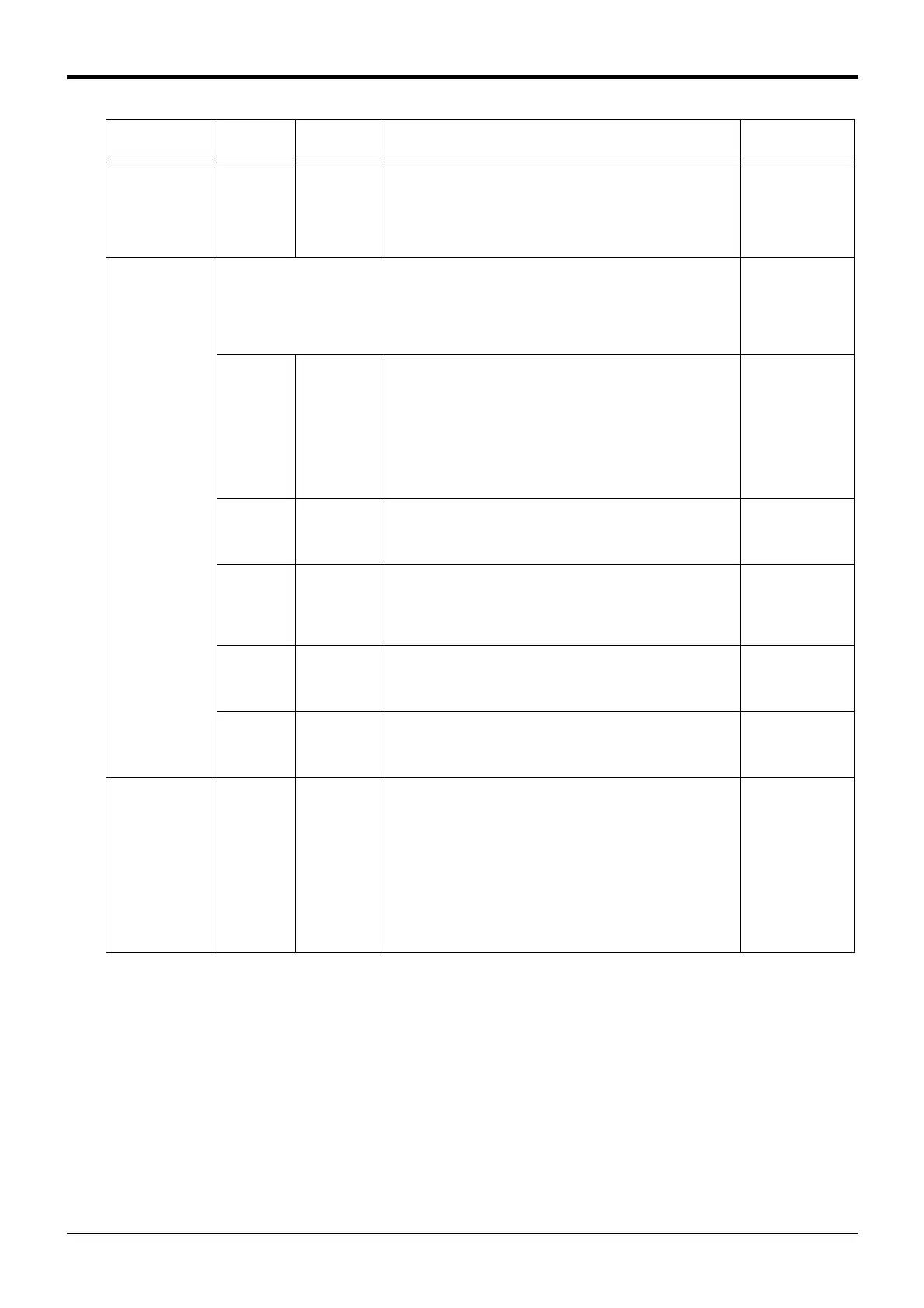

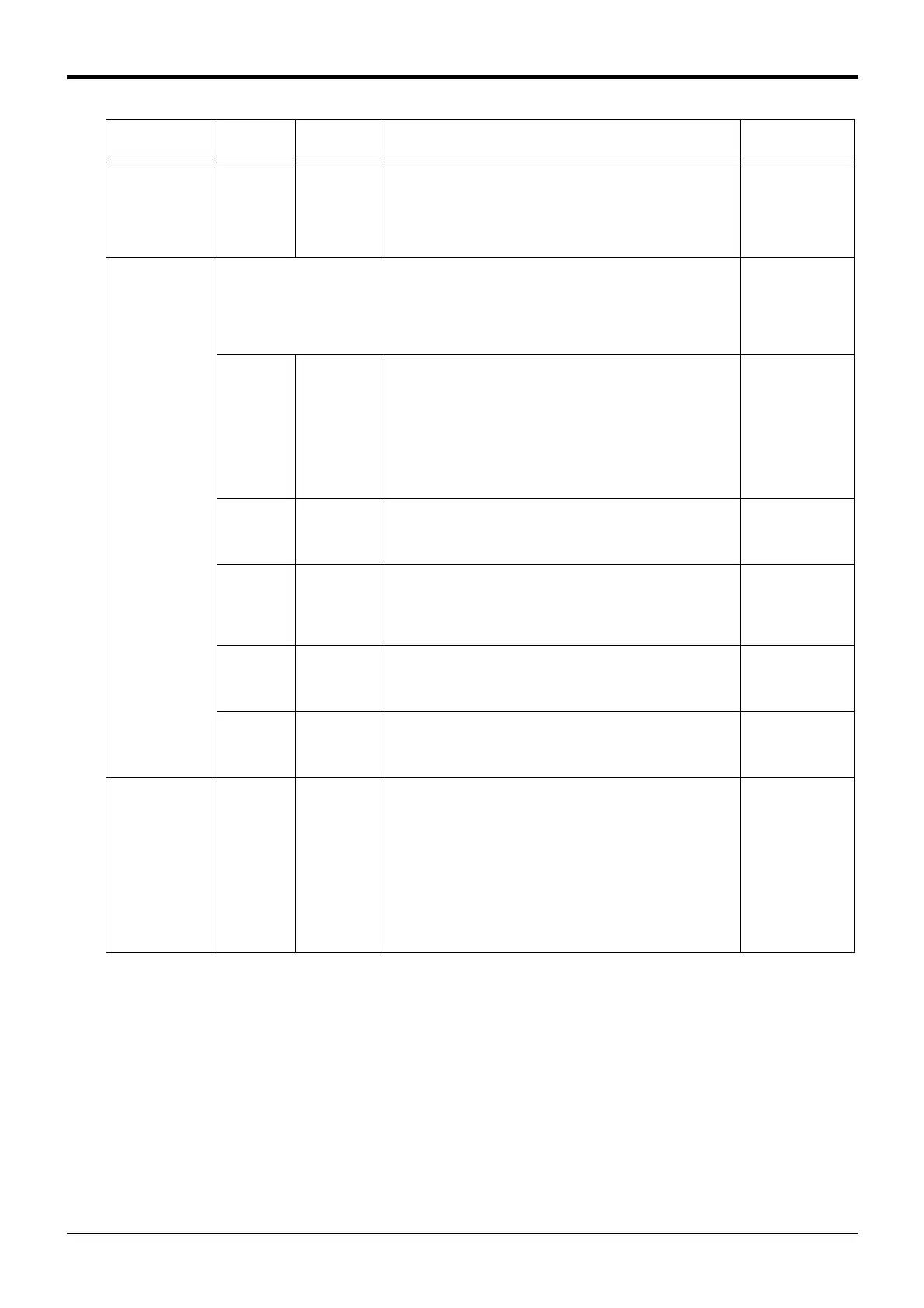

5Functions set with parameters

Movement parameter 5-447

Hand type

Refer to

"5.12About the

hand type"

HANDTYPE Character

string 8

Set the single/double solenoid hand type and output signal No.

(D: double solenoid, S: single solenoid).

Set the signal No. after the hand type.

When D900 is set, the signal No. 900 and 901 will be output.

In the case of D (double solenoid), please configure the setting

so that the signals do not overlap

CR750/CR751:

D900,D902,D904,D

906,,,,

CR760:

D764,D766,D768,D

770,,,,

Hand and work-

piece conditions

(Used in optimum

acceleration/decel-

eration and impact

detection)

Refer to "5.16Hand

and Workpiece

Conditions (opti-

mum acceleration/

deceleration set-

tings)"

Set the hand conditions and work conditions for when Oadl ON is set with the program.

Up to eight conditions can be set. The condition combination is selected with the LoadSet com-

mand.

Note) You should set up the hand and work-piece conditions correctly. If a setting is performed

in such a way that it falls below the mounted load actually, the life span of the mechanism

elements used in the robot may be shortened.

HNDDAT0 Real value 7 Set the initial condition of the hand. (Designate with the tool

coordinate system.)

Immediately after power ON, this setting value is used.

To use the impact detection function during jog operation, set the

actual hand condition before using. If it is not set, erroneous

detection may occur.

(Weight, size X, size Y, Size Z, center of gravity X, center of

gravity Y, center of gravity Z) Unit: Kg, mm

Setting value for

each mechanism

HNDDAT*

* is 1 to 8

Real value 7 Set the initial condition of the hand. (Designate with the tool

coordinate system.)

(Weight, size X, size Y, Size Z, center of gravity X, center of

gravity Y, center of gravity Z) Unit: Kg, mm

Standard load

,0.0,0.0,0.0,0.0,0.0,

0.0

WRKDAT0 Real value 7 Set the work conditions. (Designate with the tool coordinate sys-

tem.)

Immediately after power ON, this setting value is used.

(Weight, size X, size Y, Size Z, center of gravity X, center of

gravity Y, center of gravity Z) Unit: Kg, mm

0.0,0.0,0.0,0.0,0.0,0.0

,0.0

WRKDAT*

* is 1 to 8

Real value 7 Set the work conditions. (Designate with the tool coordinate sys-

tem.)

(Weight, size X, size Y, Size Z, center of gravity X, center of

gravity Y, center of gravity Z) Unit: Kg, mm

0.0,0.0,0.0,0.0,0.0,0

.0,0.0

HNDHOLD*

* is 1 to 8

Integer 2 Set whether to grasp or not grasp the workpiece when HOpen

(or HClose) is executed.

(Setting for Open, setting for Close)

(No grasp/grasp = 0/1)

0,1

Maximum acceler-

ation/deceleration

setting

Refer to "5.16Hand

and Workpiece

Conditions (opti-

mum acceleration/

deceleration set-

tings)"

ACCMODE Integer 1 Sets the initial value and enables/disables the optimum acceler-

ation/deceleration mode. (Invalid/Valid=0/1)

1

Parameter

Parameter

name

No. of arrays

No. of characters

Details explanation Factory setting

Loading...

Loading...